Combined heat and power (CHP) system

a heat exchanger and heat exchanger technology, applied in the direction of heat exchanger fastening, machines/engines, light and heating apparatus, etc., can solve the problems of reduced heat exchanger efficiency, increased exhaust of small particles by exhaust, contamination of filters and catalysts, etc., to achieve high reliability and efficiency, less prone to contamination, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

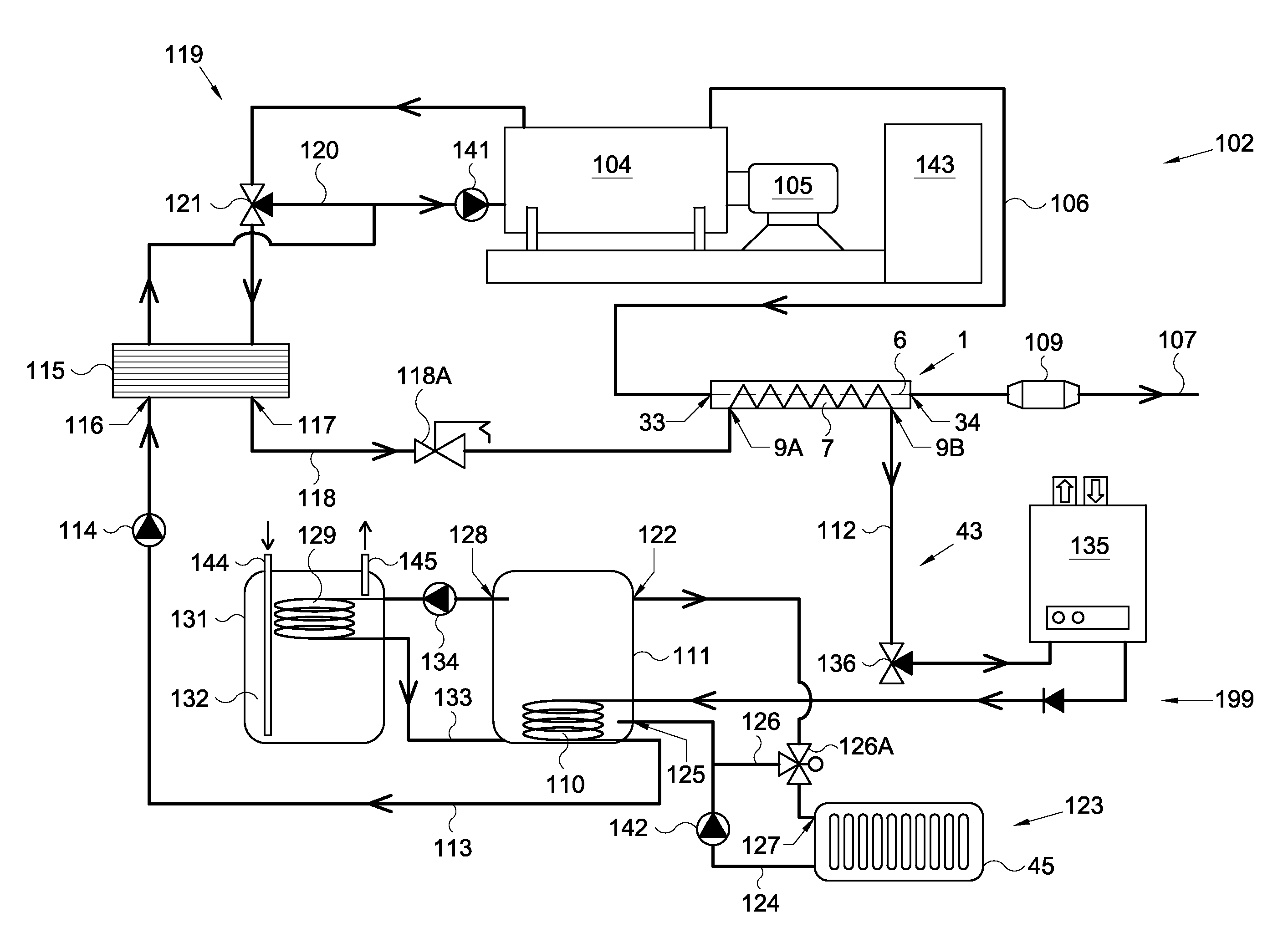

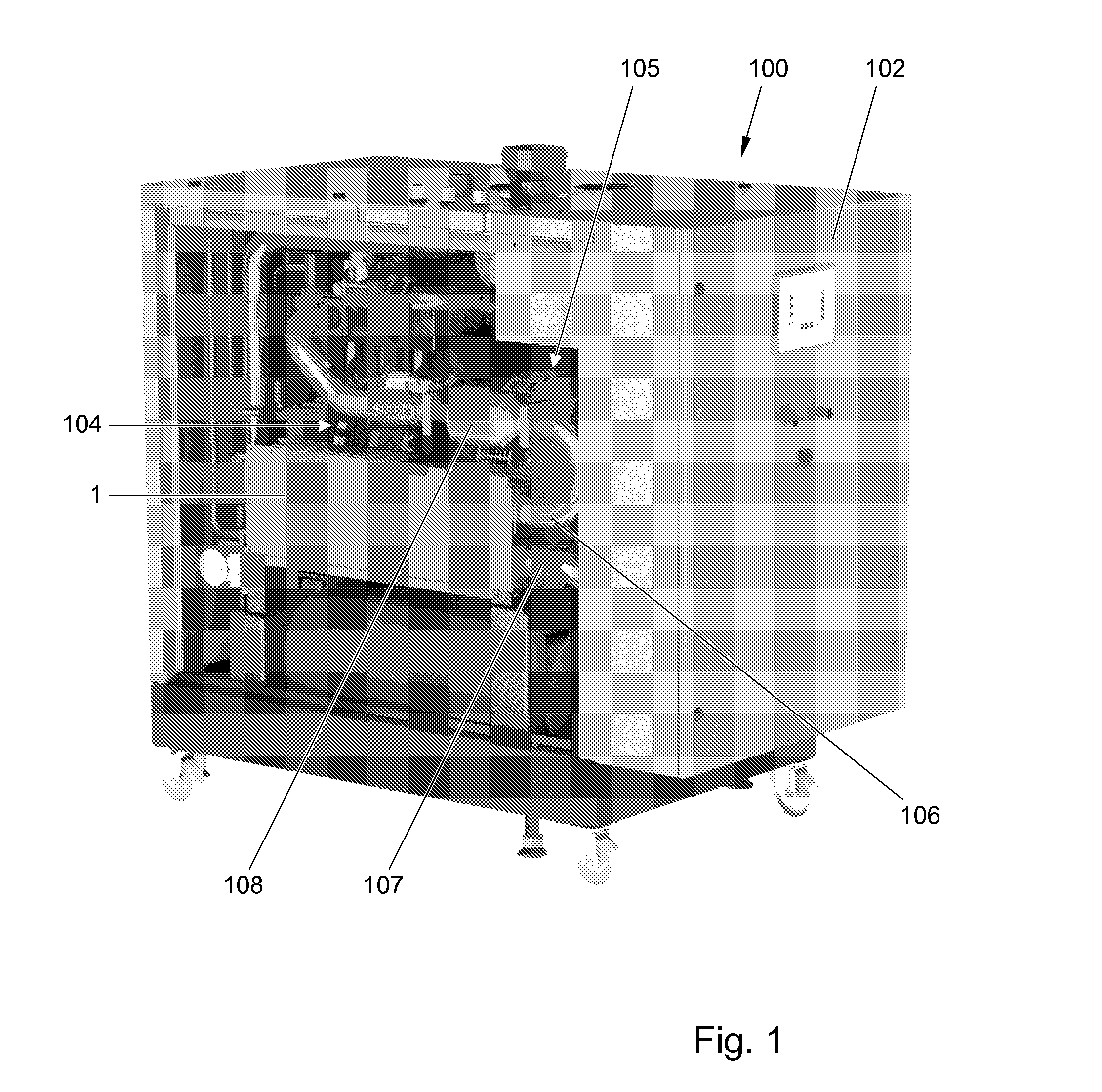

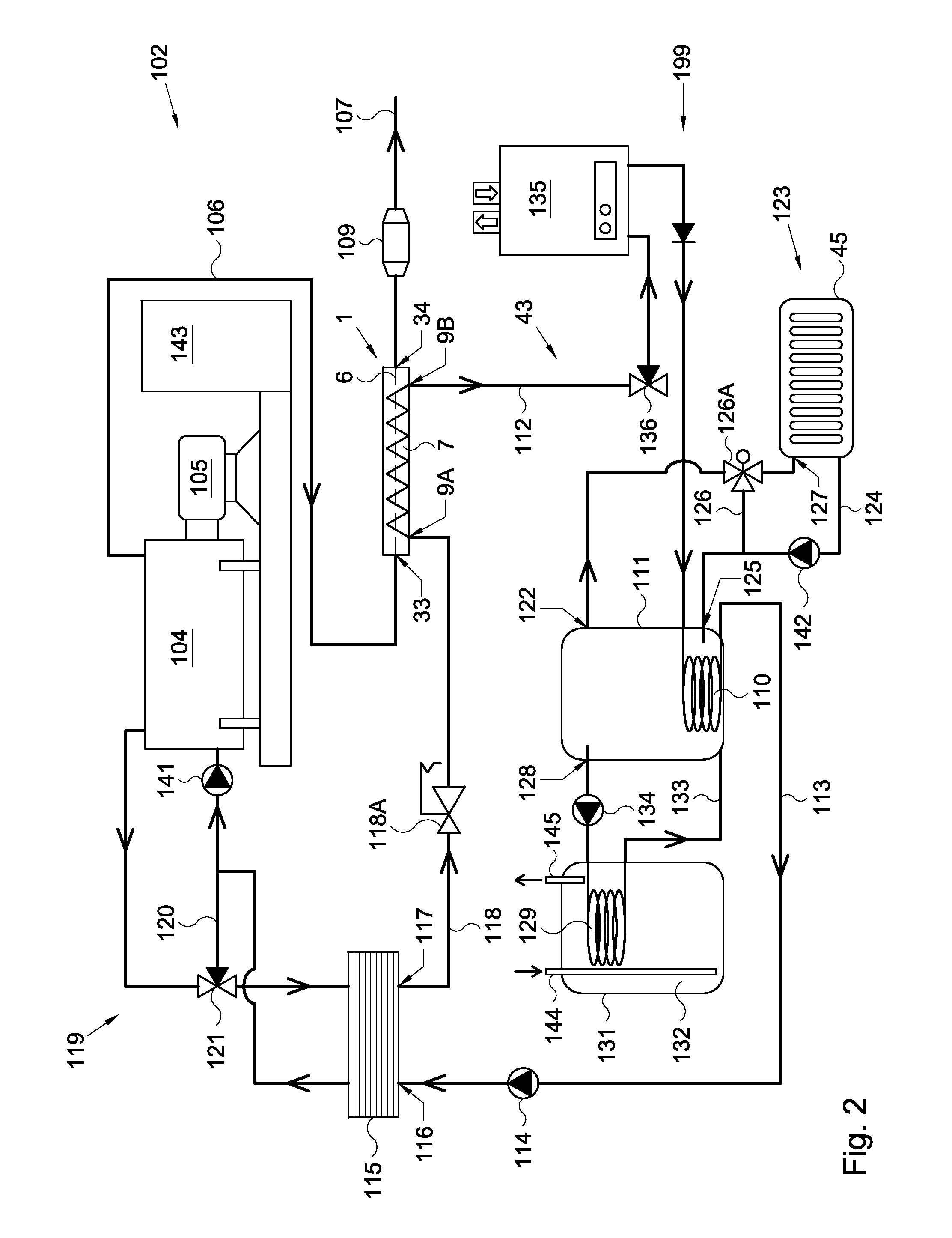

[0032]In this description different embodiments of a CHP system and parts thereof are disclosed and described. Moreover, in this description different embodiments of heat exchangers and parts thereof for such CHP systems, as well as heating circuits equipped therewith are disclosed and described by way of example only. In these embodiments the same or similar parts have the same or similar reference signs. Combinations of parts of the embodiments shown are also considered to have been disclosed herein. In this description a heat exchanger as to be understood as an exchanger for exchanging heat between heated flue gasses from an engine or turbine and possibly additionally a burner and water flowing through one or more water channels within said heat exchanger. Such CHP systems are especially, but not exclusively suitable in domestic and commercial heating systems such as for sanitary (tap) water and central heating systems, such as for space heating and / or tap water heating systems.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com