Low Energy Gasifier-Liquefier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

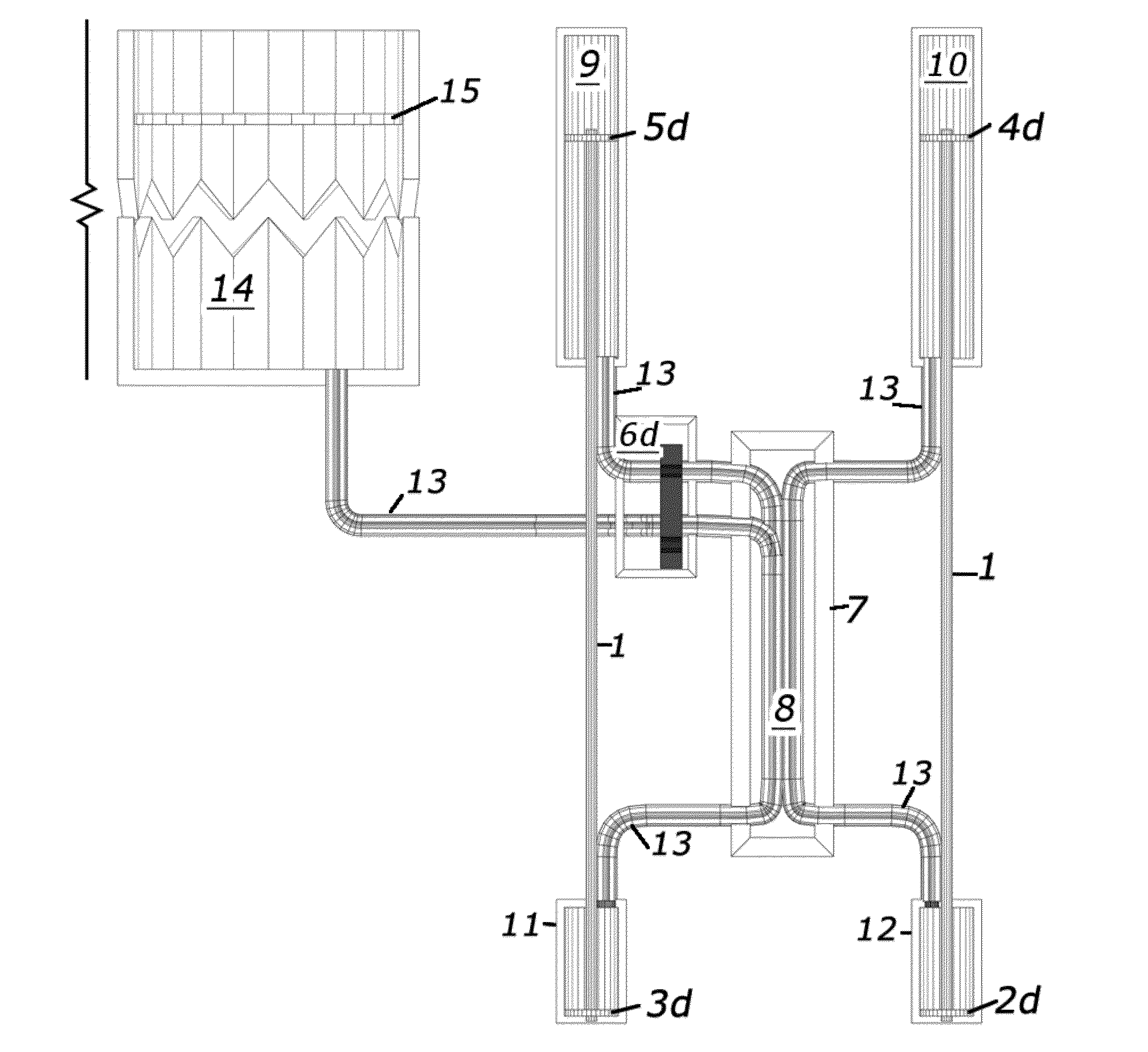

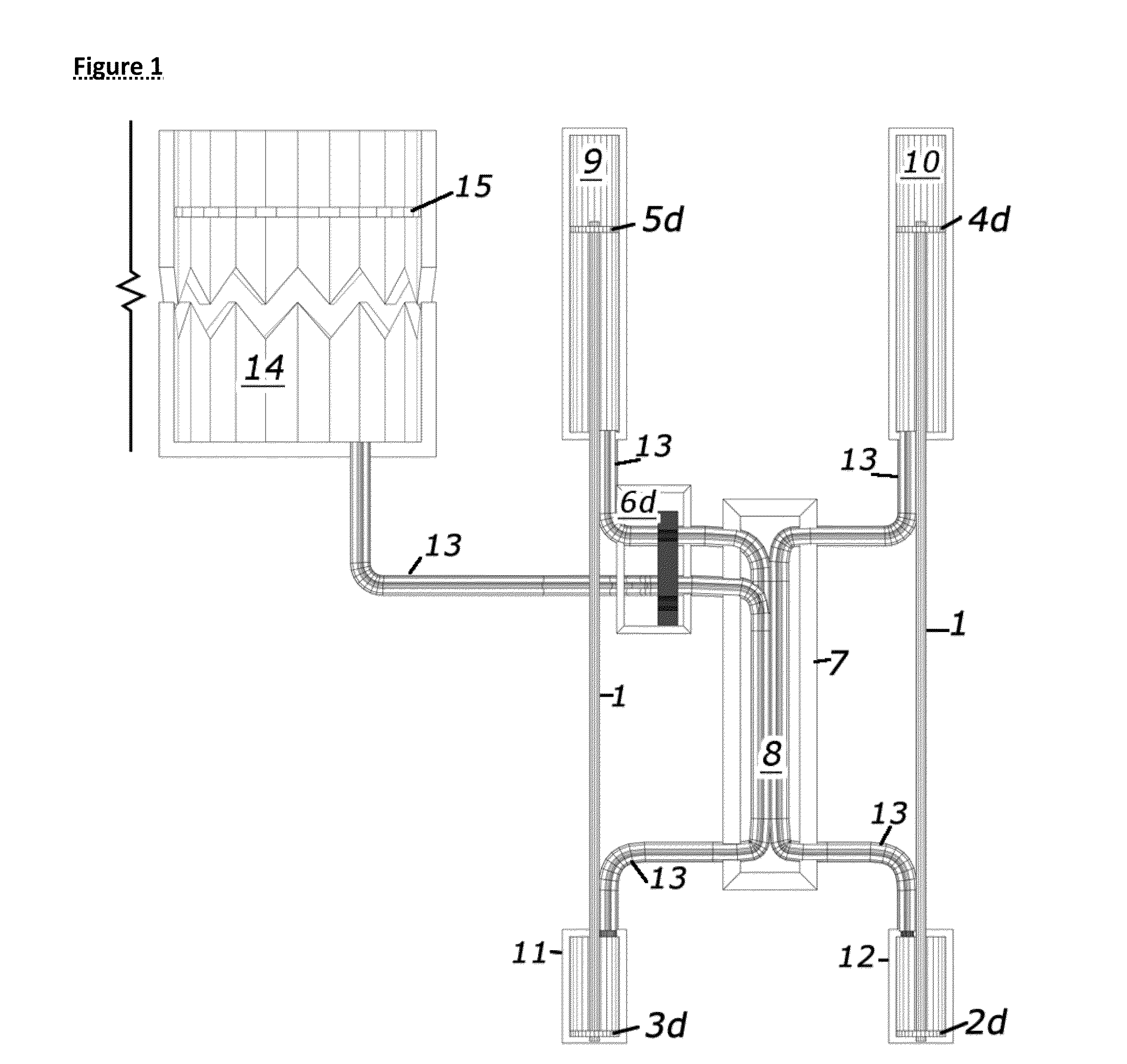

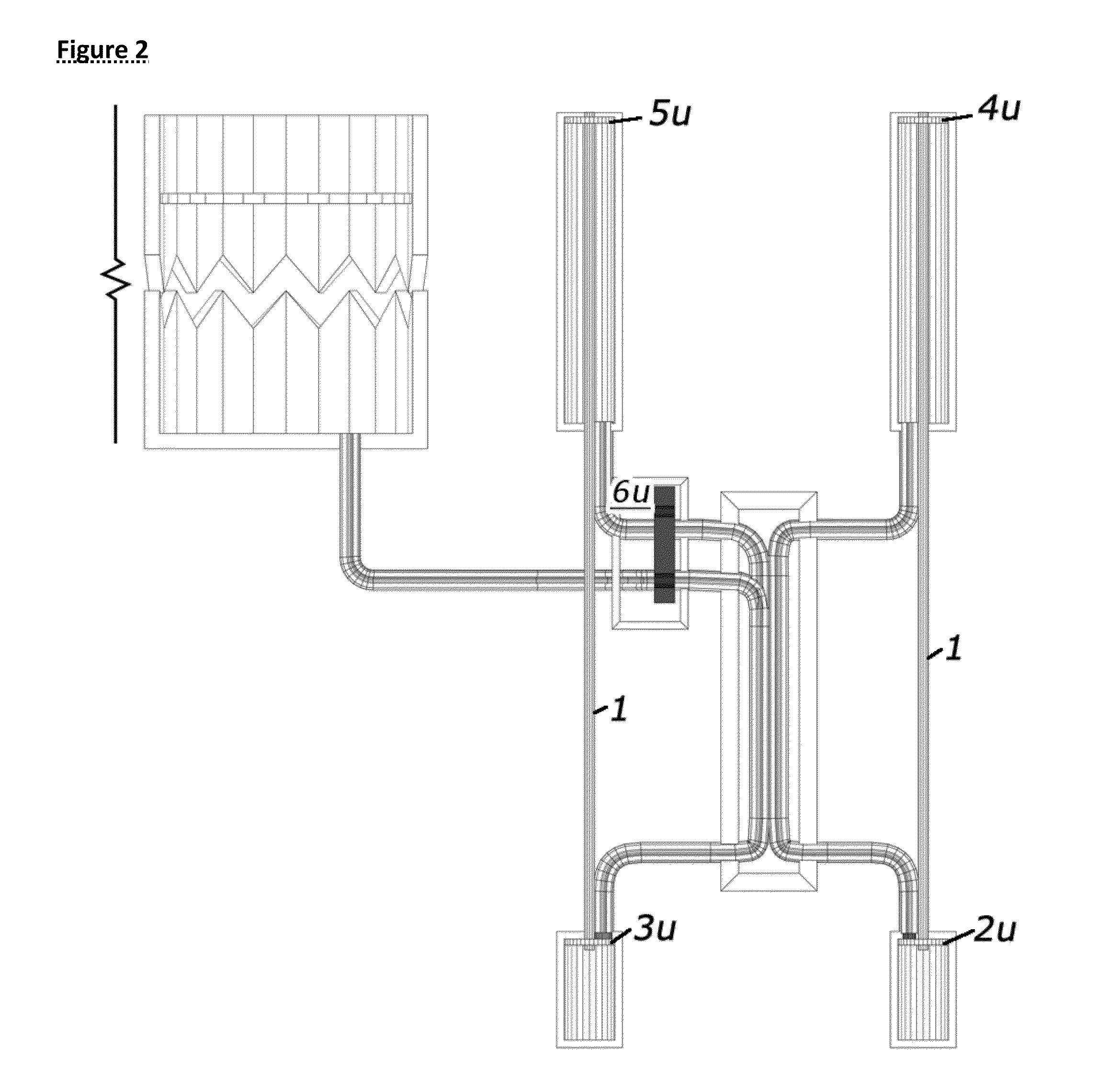

[0047]Both devices are based on a combination of counter flow heat exchangers (Patent A) and reservoirs of heat or cold. (Technically a cold reservoir is more accurately described as having less heat).

[0048]The fluids should be matched in thermal capacity. With the same type of material in both chambers, this simply means an equal mass of fluid. It would simplify the system to have a reservoir that remains in liquid state, if a material is available that is liquid over the required temperature range.

[0049]If liquid is to be cycled to gas and back to liquid, a hot fluid reservoir is required.

[0050]If a gas (vapor) is to be cycled to liquid and back to gas, a cold fluid reservoir is required.

[0051]In either case, optimal efficiency will be when the reservoir temperatures are just above or just below the boiling point.

[0052]The reservoir temperature is independent of the temperature of the fluid to have phase changed. It simply must have enough heat or cold capacity to supply or exhaus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com