Polymer grouting method for constructing gravel pile

a technology of gravel piles and polymer grouting, which is applied in the direction of bulkheads/piles, construction, foundation engineering, etc., can solve the problems of affecting the long-term stability of the roadbed, and dramatically reducing the foundation strength of the natural loess, so as to achieve high efficiency, high strength, and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention is further explained in detail with the accompanying drawings.

[0039]A polymer gravel pile grouting method comprises steps of:

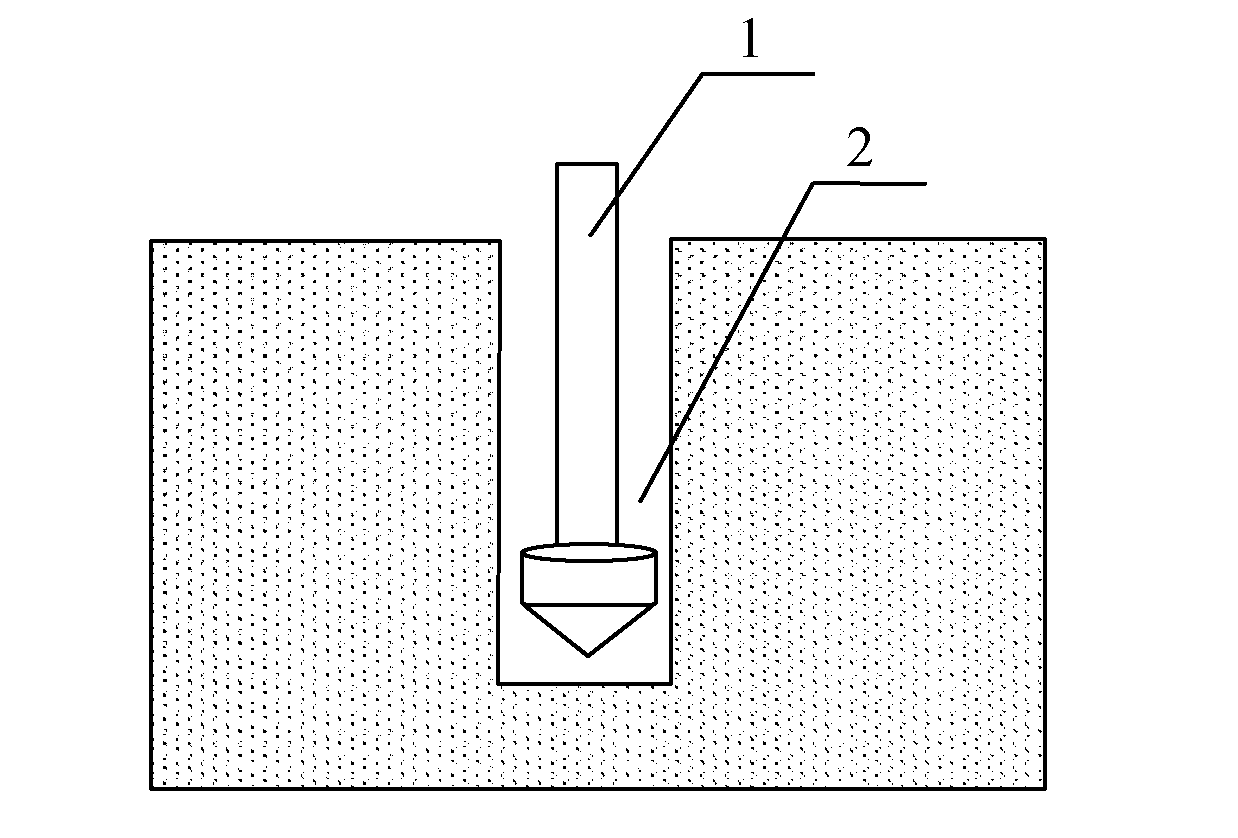

[0040](1) pile-position-pore-forming: according to design requirements, constructing a pile hole at a pile position by a drilling tool 1, whose depth reaches a design depth, as shown in FIG. 1;

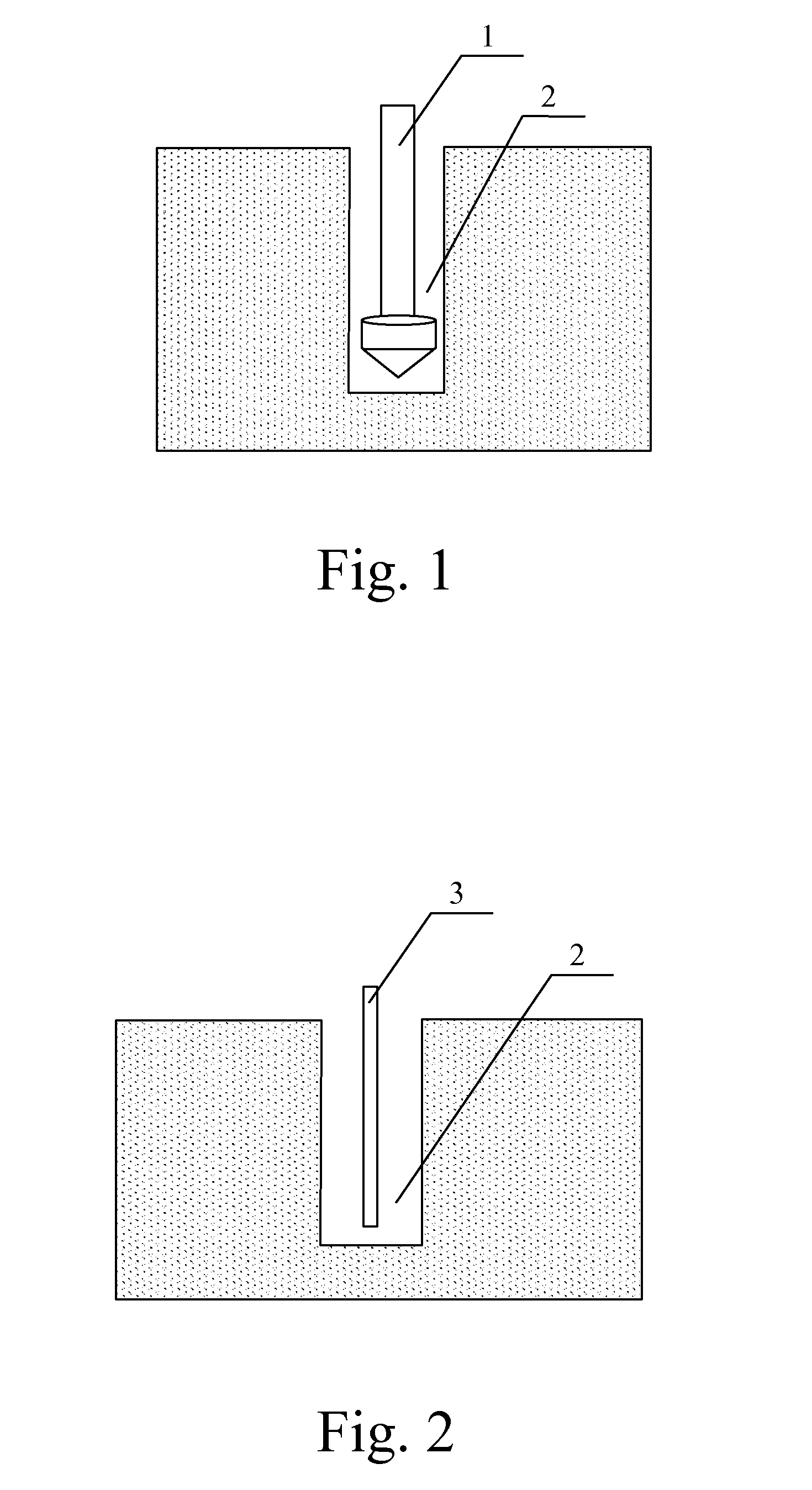

[0041](2) installing a grouting pipe: installing a grouting pipe 3 in the pile hole 2, wherein the grouting pipe 3 is located in a middle of the pile hole, and a grouting outlet of the grouting pipe 3 is close to a bottom of the pile hole 2, as shown in FIG. 2;

[0042](3) putting graded stones: according to different geological conditions, putting graded stones 4 into the pile hole, as shown in FIG. 3;

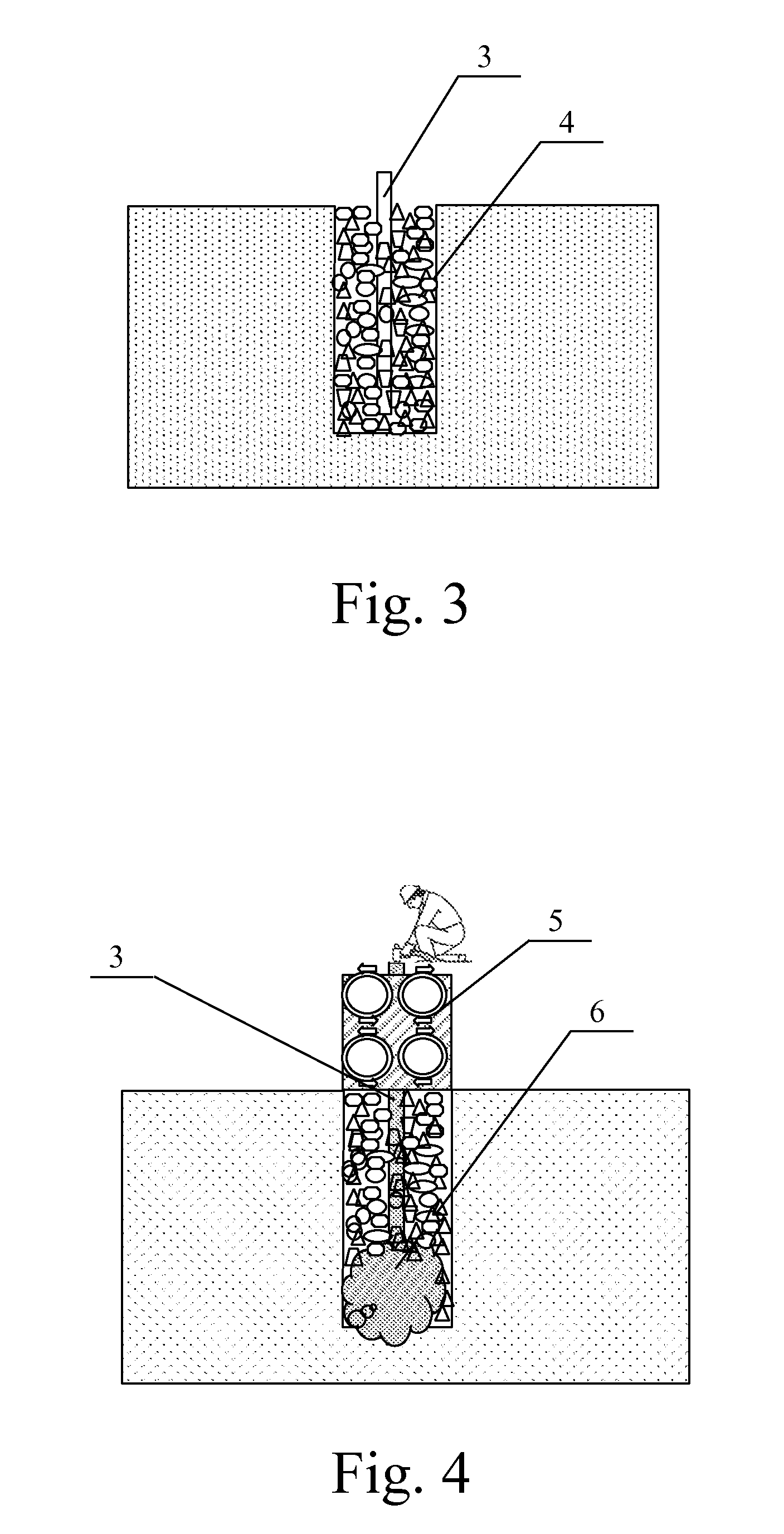

[0043](4) polymer lifting grouting: putting a polymer lifting grouting control equipment 5 on a hole of the grouting pipe 3; placing the grouting pipe 3 into a pipe fixing device of the polymer lifting grouting control equipment 5; injecting two-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com