Multijunction photovoltaic device having sige(SN) and gaasnsb cells

a photovoltaic device and multi-junction technology, applied in photovoltaic energy generation, electrical equipment, climate sustainability, etc., can solve the problems of limited pattern matching and introduce defects into the structure, and achieve good absorption coverage of the spectral wavelengths longer, small band gap, and high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

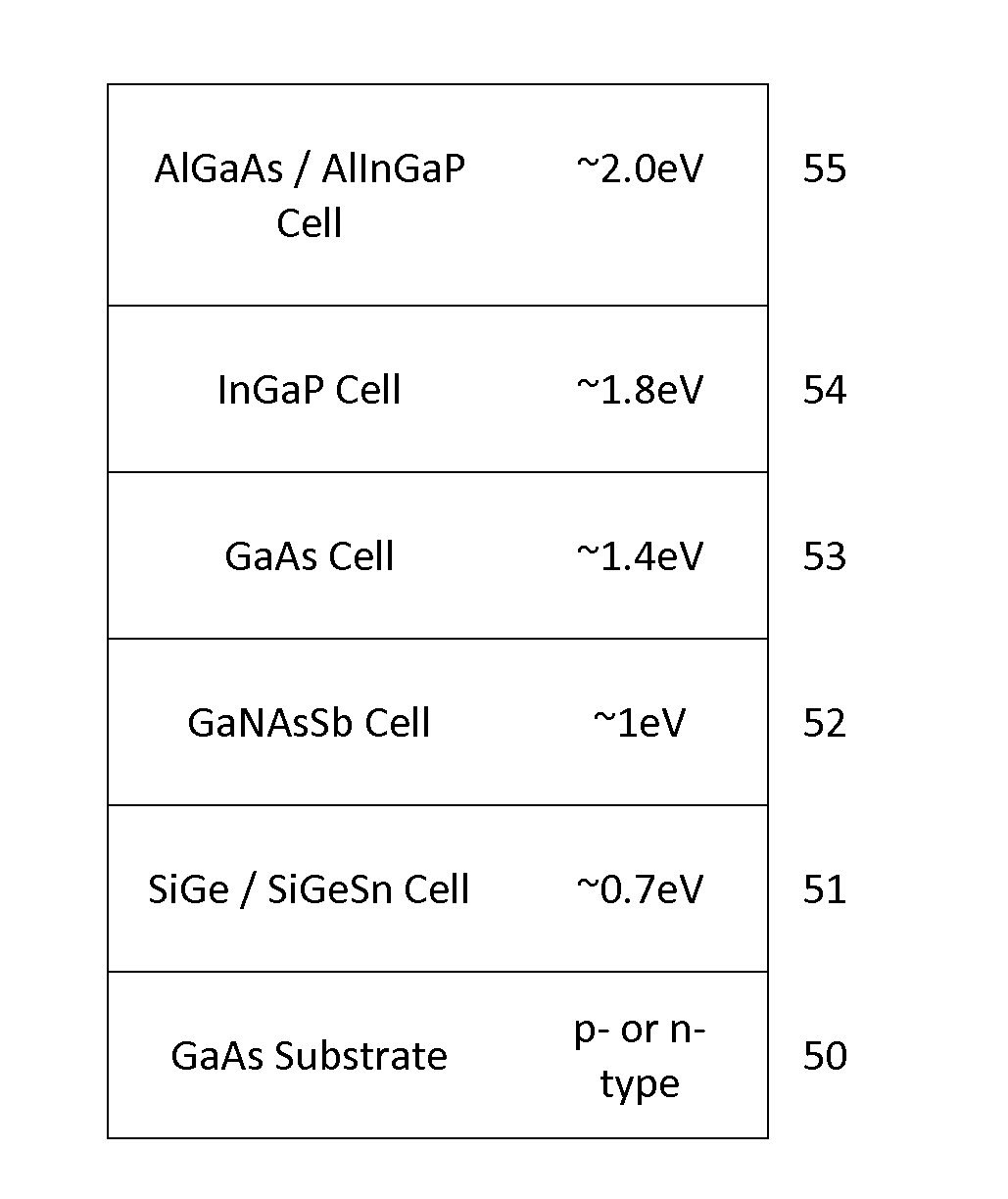

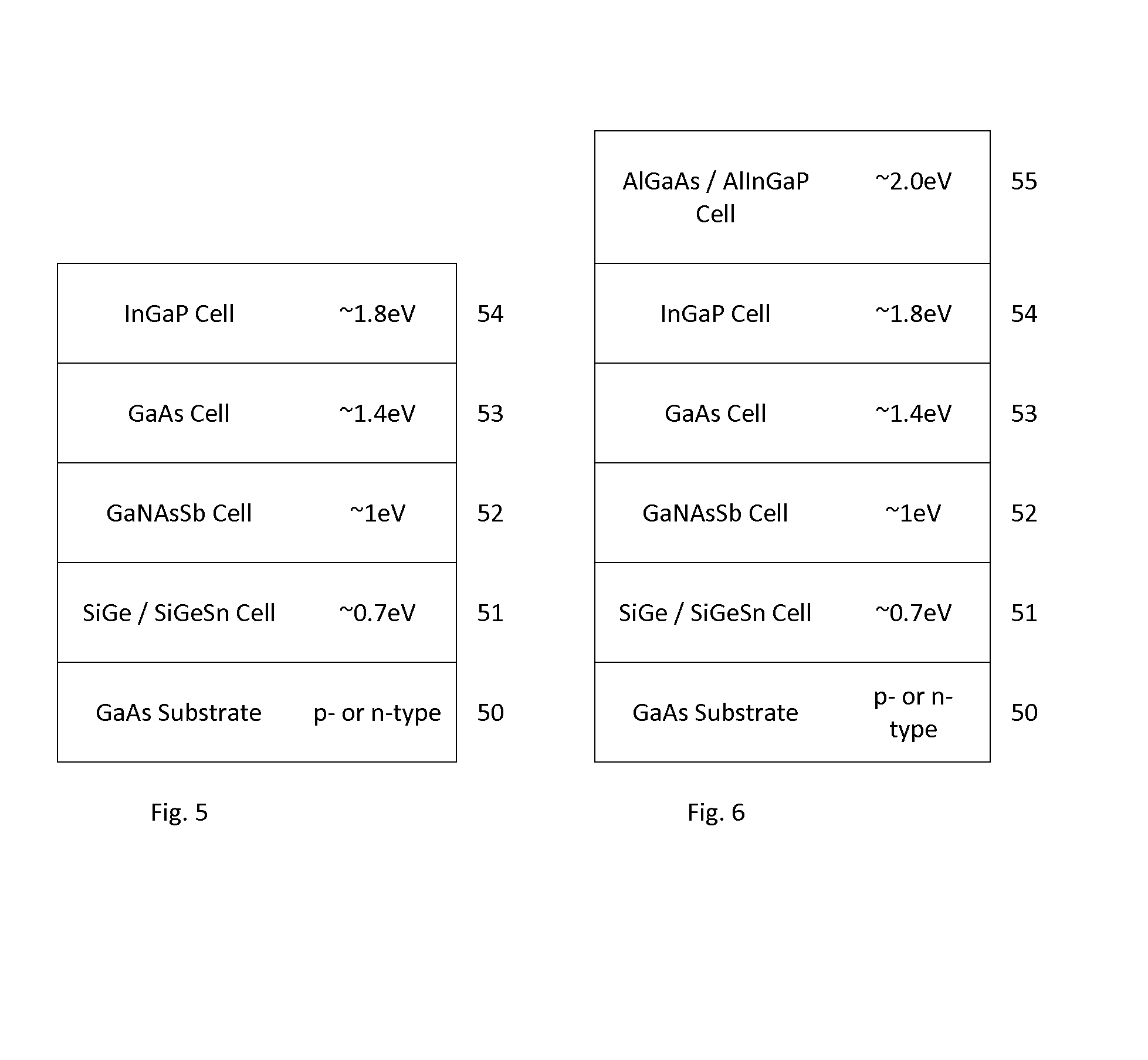

[0045]FIG. 5 shows the subcells of first example of a multijunction photovoltaic device, in particular a solar cell, in accordance with the invention. This comprises a series of subcells to absorb incident light, formed on a GaAs substrate 50. The light is first incident on the subcell 54, which in this example is furthest from the substrate, with light not absorbed by each subcell passing to the next. In this example there are a top subcell 54 comprising a light absorbing layer of InGaP material, an upper middle subcell 53 comprising a light absorbing layer of GaAs 52 and a lower middle subcell comprising a light absorbing layer of GaNAsSb material and a bottom subcell 51 comprising a light absorbing layer of SiGe material, all of which are lattice matched to a GaAs substrate 50. The light absorbing material layer of each of these subcells contains a p-n junction to separate the photocarriers generated. Preferably the cells are connected in series (tandem cell).

[0046]In this exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice matched | aaaaa | aaaaa |

| lattice | aaaaa | aaaaa |

| spectrum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com