Method and system for realtime performance recovery advisory for centrifugal compressors

a centrifugal compressor and real-time performance recovery technology, applied in the direction of electric controllers, program control, instruments, etc., can solve the problems of difficult follow-up action (advisory), deterioration of the performance of these machines, and lack of detailed design information of known monitoring systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The following detailed description illustrates embodiments of the invention by way of example and not by way of limitation. It is contemplated that the invention has general application to analytical and methodical embodiments of monitoring equipment operation in industrial, commercial, and residential applications.

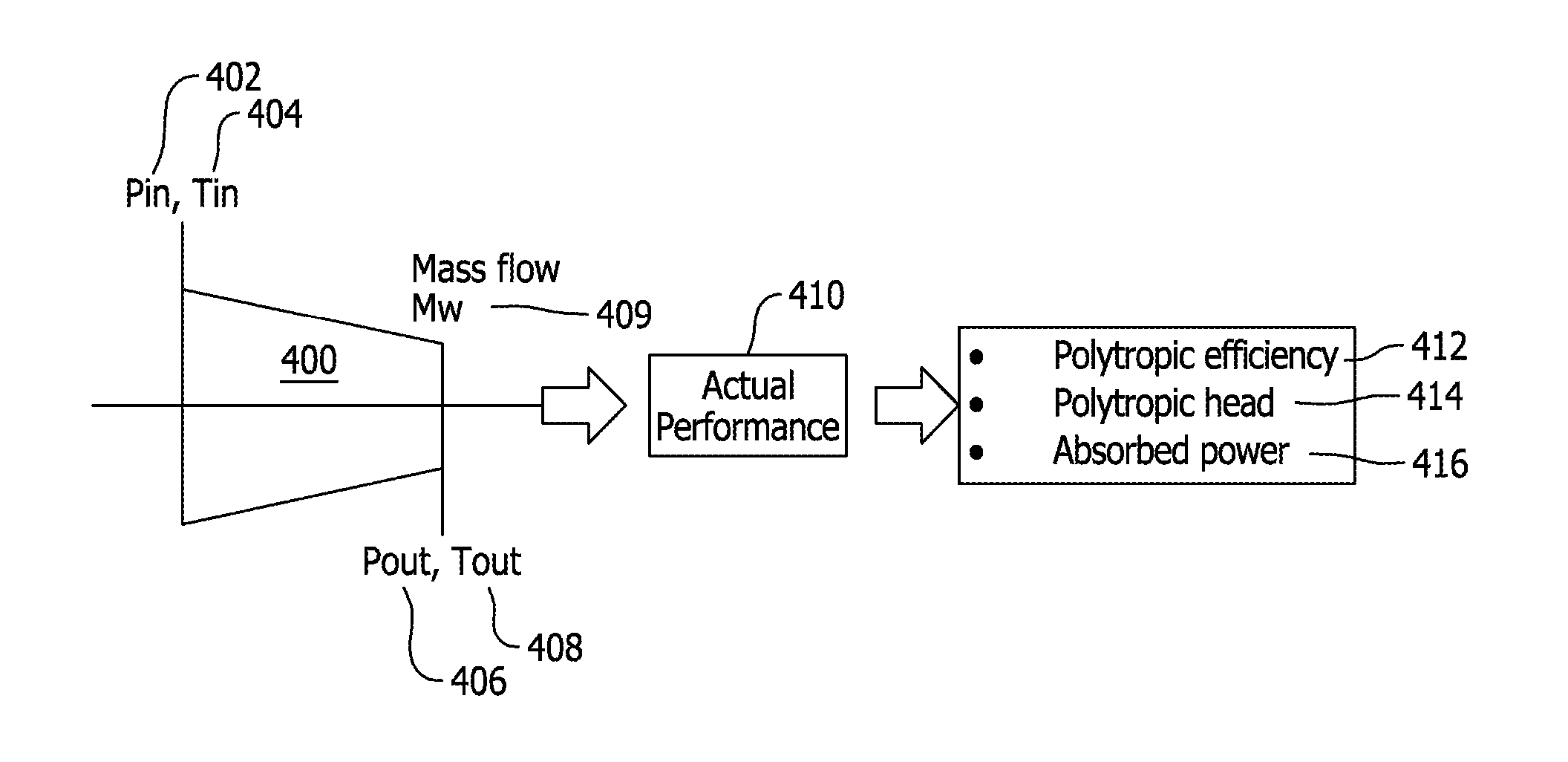

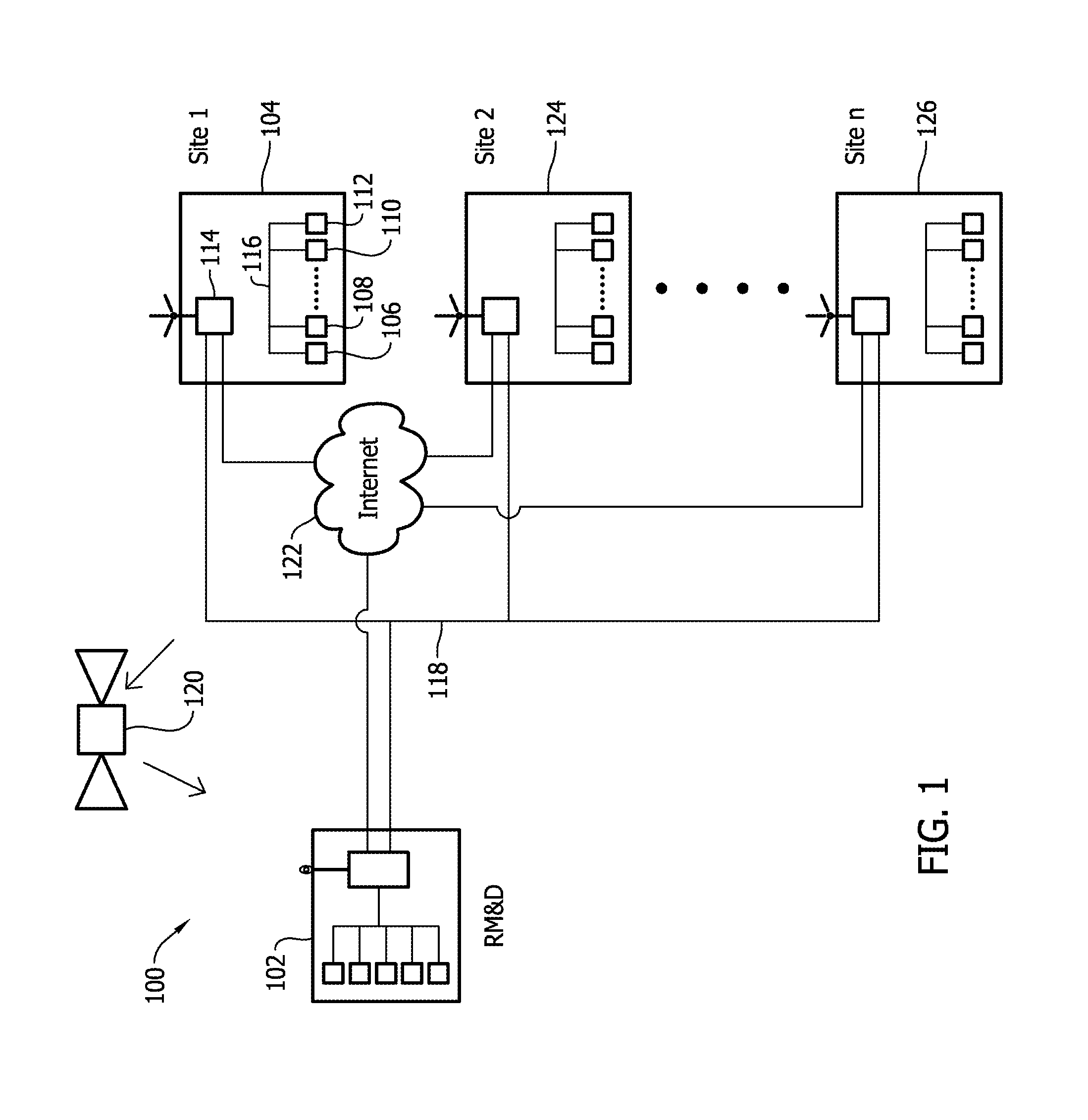

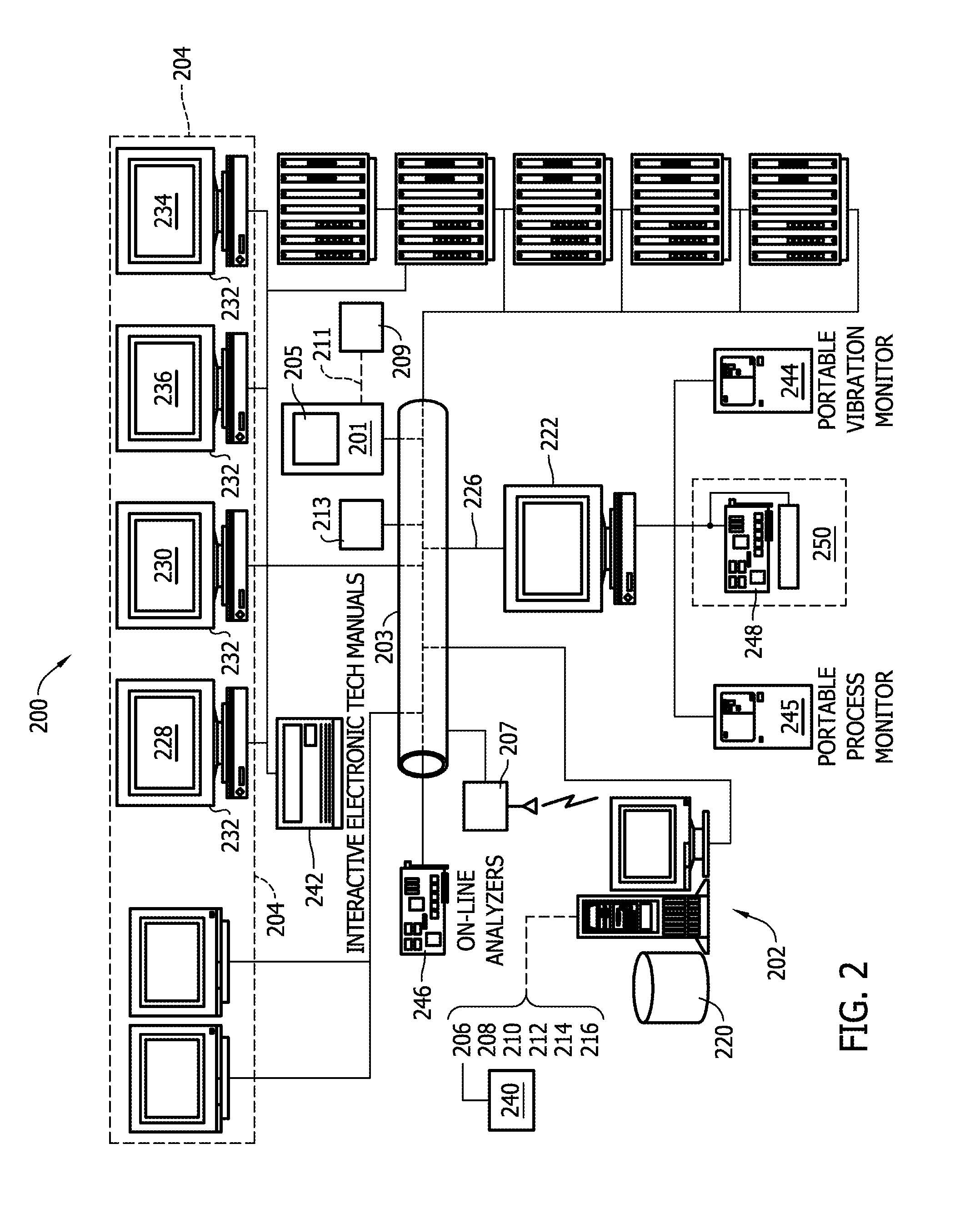

[0020]As described herein a centrifugal compressor performance recovery rule set provides a methodology that utilizes optimization techniques to provide performance recovery advisory information to operators of a centrifugal compressor. The operators can interface with the tool to provide new / existing operating conditions and request solutions that can improve operating margins of the centrifugal compressor. OEM design information and ‘as-new’ test data are embedded in the rule set to provide an accuracy of the evaluation that can not be obtained with the data. Moreover, to improve computational speed only a subset of the OEM design information relevant to the parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com