Composite engineered floor board having an oriented strand board (OSB) stabilizing base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

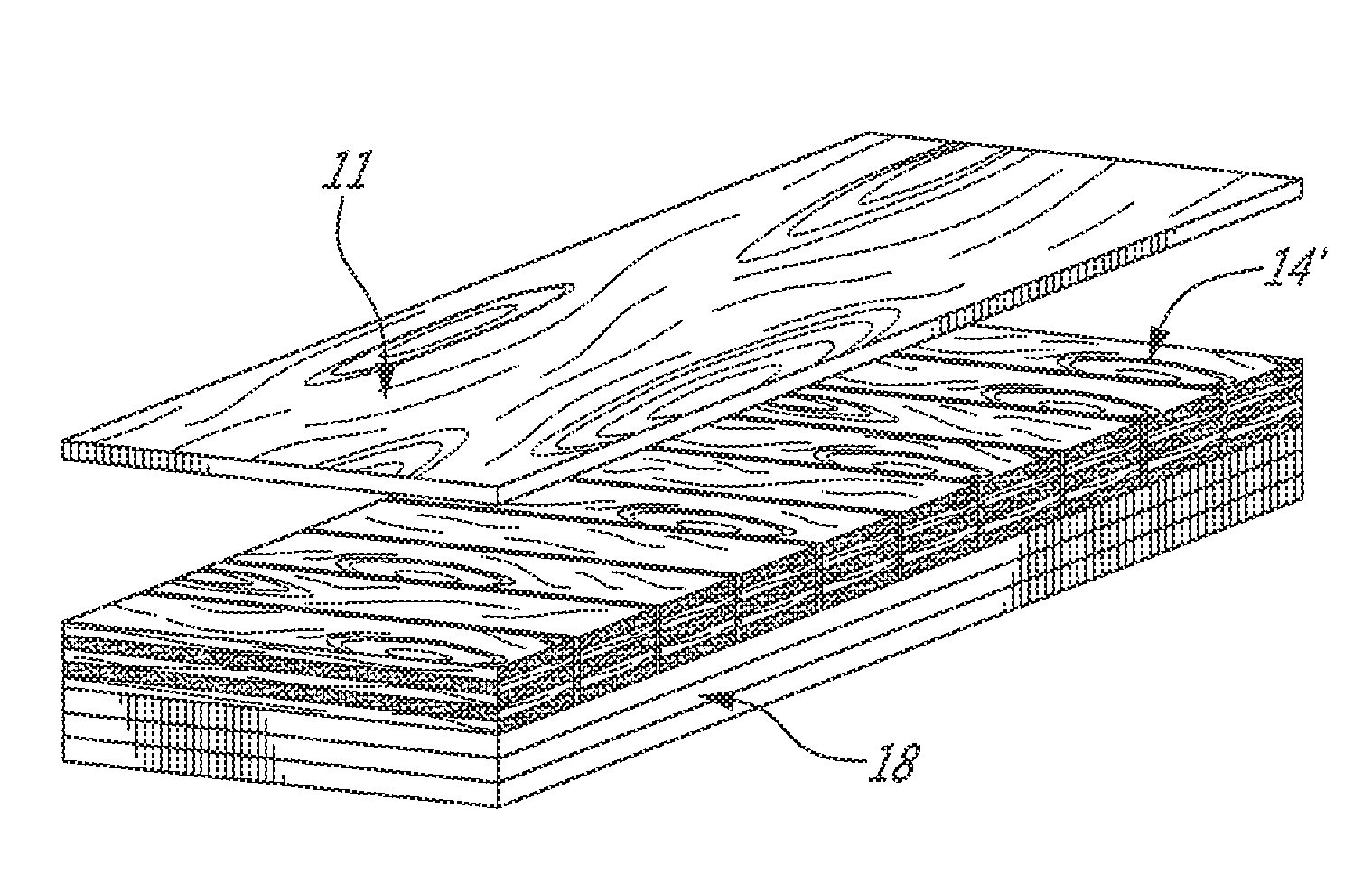

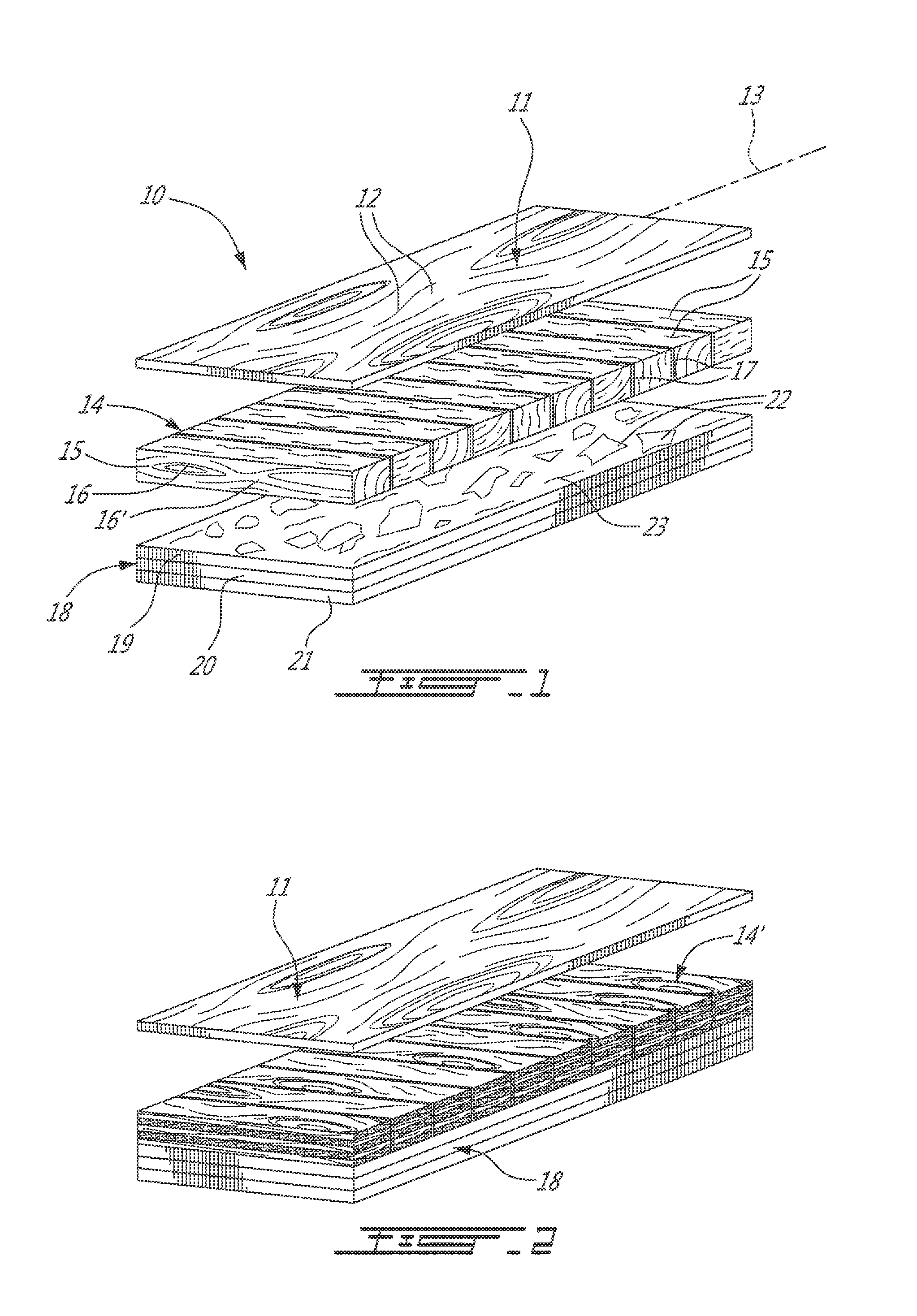

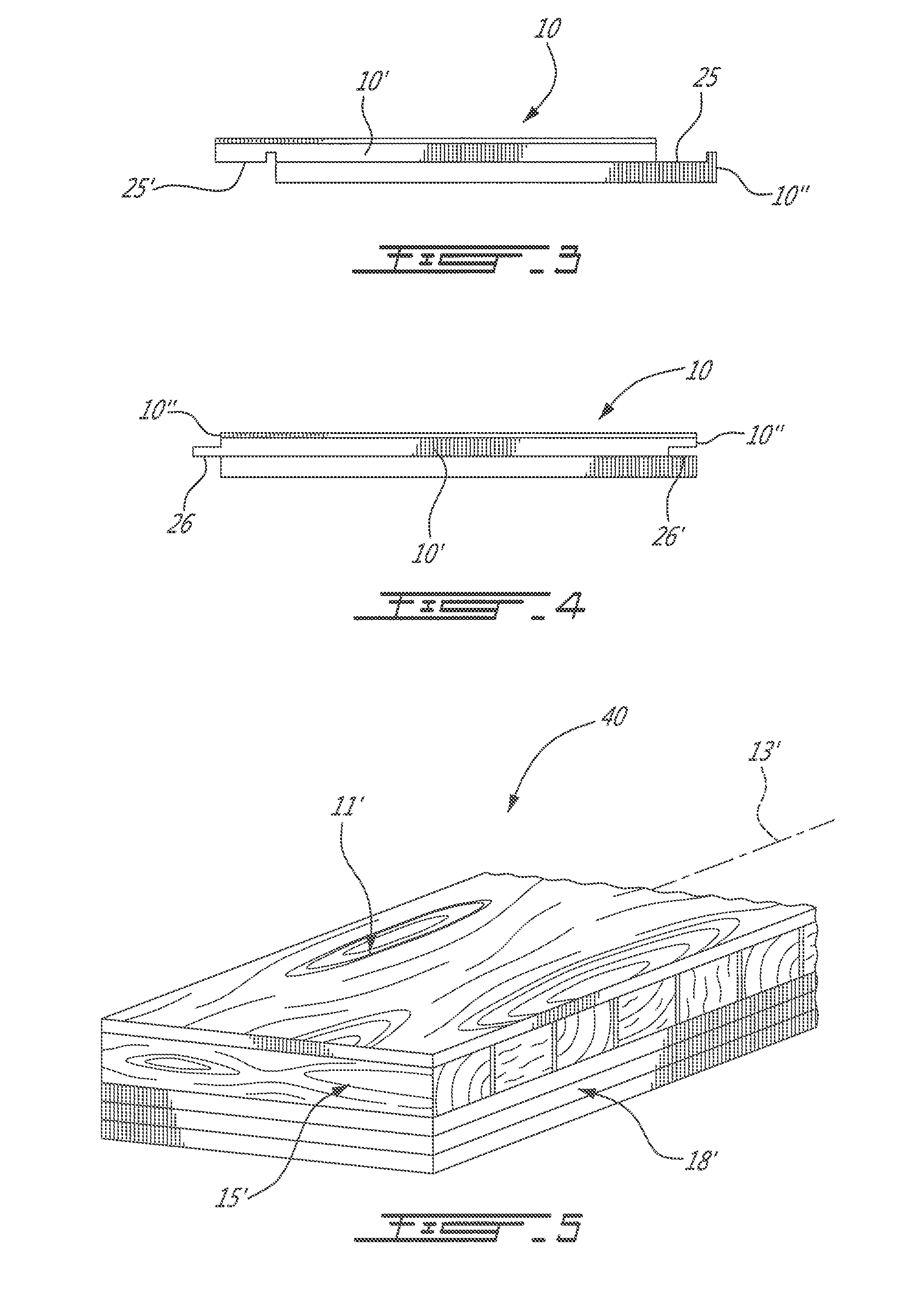

[0015]Referring to the drawings and more particularly to FIGS. 1 and 2 there is shown generally at 10 the engineered floor board of the present invention and comprised of a thin top wood layer 11 fabricated from a quality wood material such as oak, maple or many other quality wood product as is wellknown to a person skilled in the art. Preferably, the top wood layer 11 has its wood grain 12 oriented along the longitudinal axis 13 of the top wood layer 11 or the floor board 10.

[0016]The top wood layer 11 is glued to a core layer 14 which is shown in FIG. 1 as constituted by a plurality of rectangular wood slats 15 disposed in side-by-side relationship and extending transverse to the longitudinal axis 13 of the top wood layer 11. The core layer 14 is fabricated from an inferior wood product such as spruce material which is a resinous material and which may contain imperfections 16 therein. The wood slats 15 may be disposed in abutting relationship or in space relationship as herein sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com