Oxygen-Deficient Thermally Produced Processed Biochar from Beneficiated Organic-Carbon-Containing Feedstock

a biochar and thermal processing technology, which is applied in the direction of gaseous fuels, combustible gas production, separation processes, etc., can solve the problems of increasing the cost of fuel obtained from crude oil, natural gas, coal, and increasing the world-wide demand for energy at the same time, so as to reduce the adverse corrosion wear and maintenance cleaning of the device, the effect of high energy density and low water conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

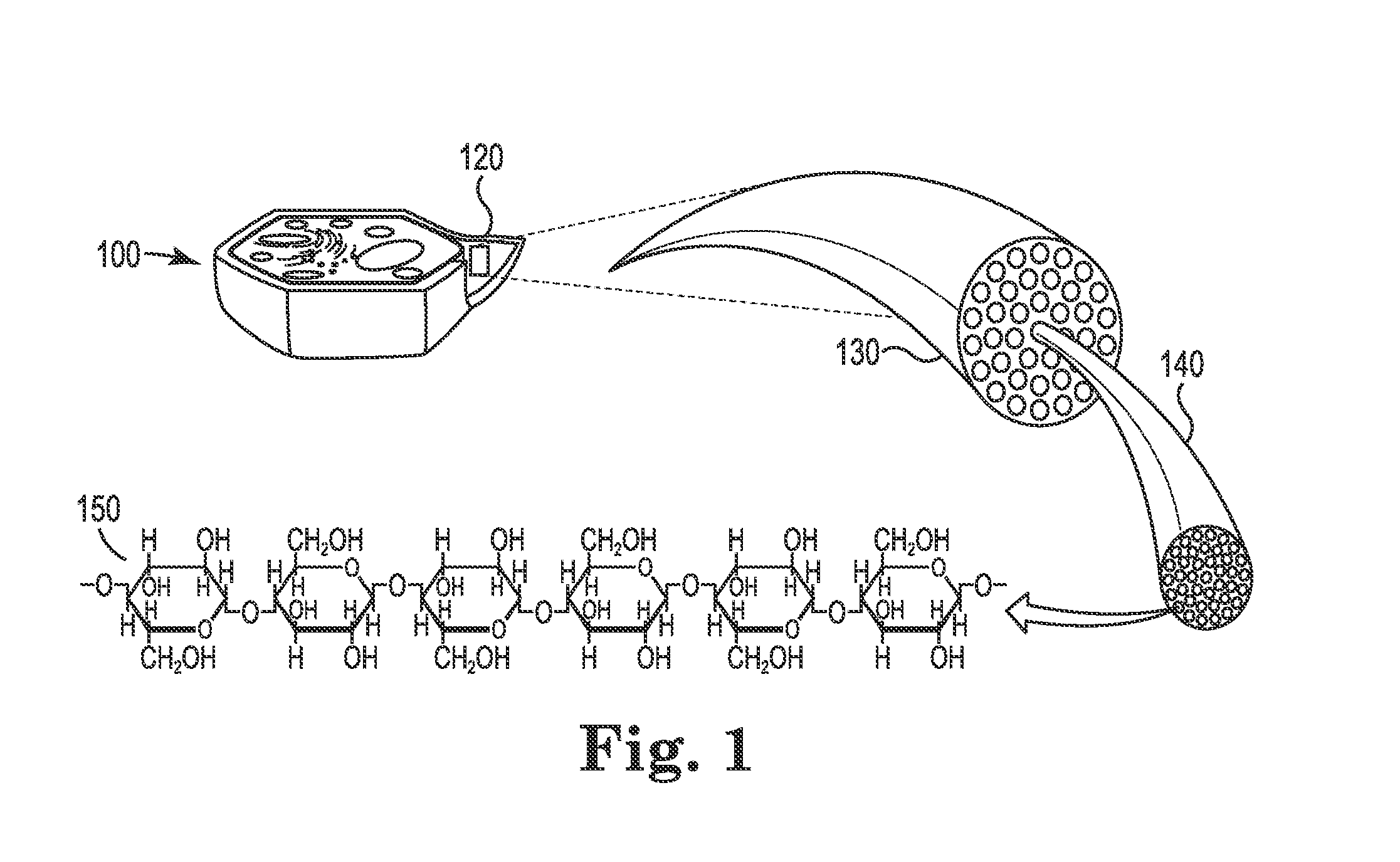

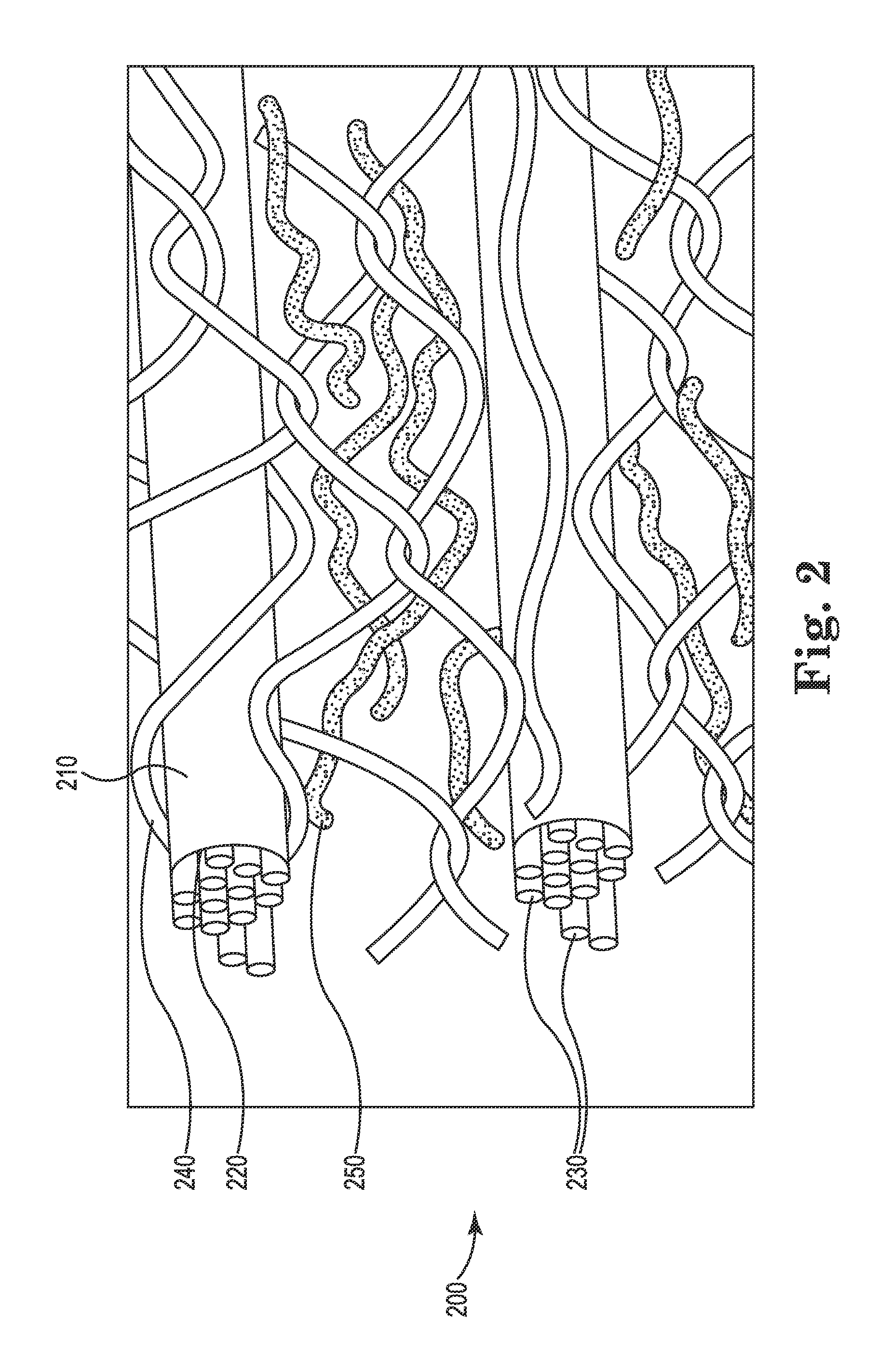

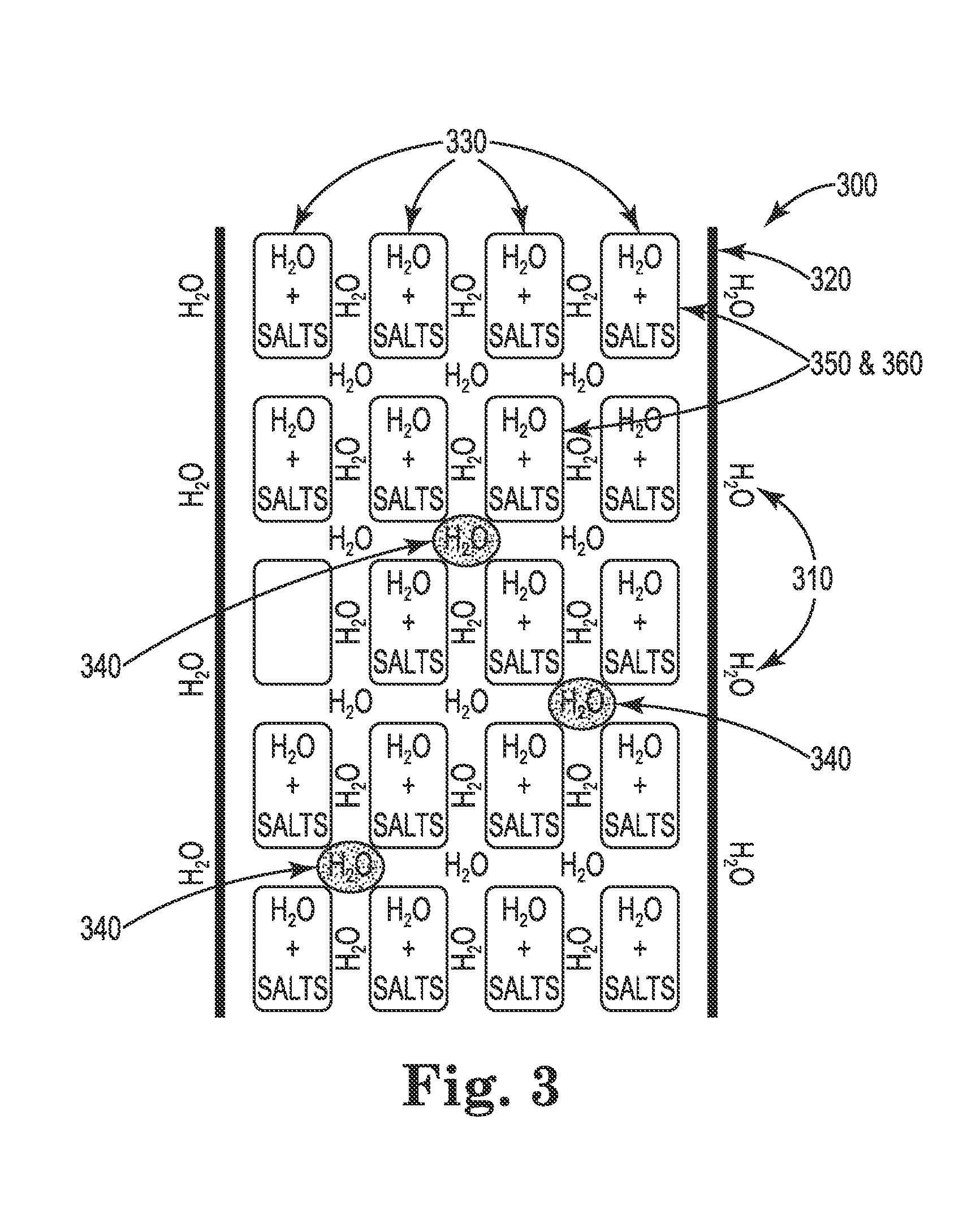

[0050]The processed biochar of the invention is a char made from passing beneficiated processed organic-carbon-containing feedstock through an oxygen-deficient thermal system. The processed biochar is similar to coal in energy density. The processed biochar of the invention has the advantages of coming from a renewable source, i.e., agricultural and plant materials, without the burdens of current biomass processes that are inefficient and remove less if any of the salt found in unprocessed renewable biomass. There are several aspects of the invention that will be discussed: biochar, unprocessed renewable organic-carbon-containing feedstock, beneficiation sub-system, oxygen-deficient thermal sub-system, beneficiation sub-system process, and oxygen-deficient thermal sub-system process.

[0051]Char made from renewable organic-carbon-containing feedstock is referred to as processed biochar in this document. The processed biochar of the invention comprises a solid carbon fuel compri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sublimation temperatures | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com