Apparatus for acoustic damping and operational control of damping, cooling, and emissions in a gas turbine engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

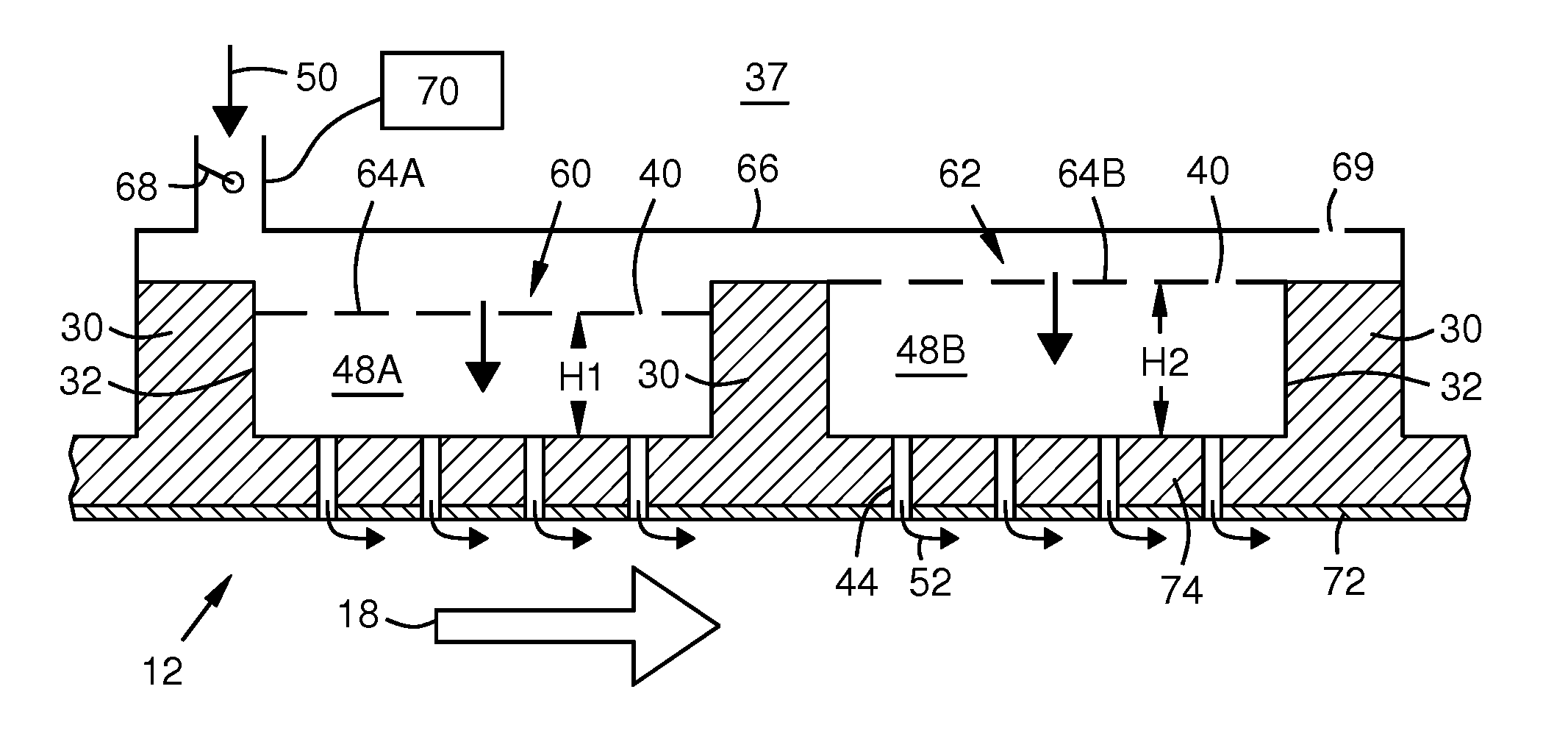

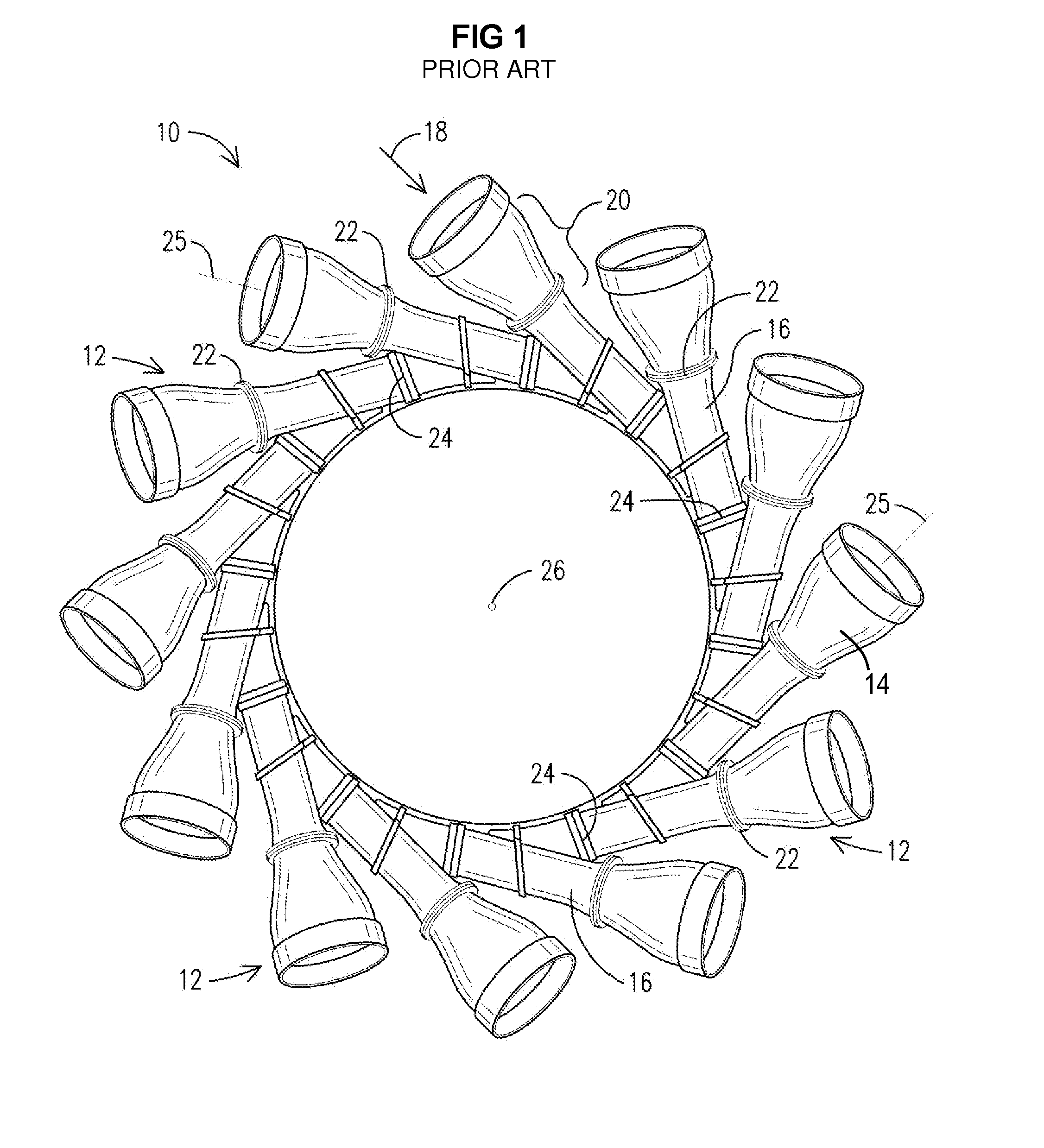

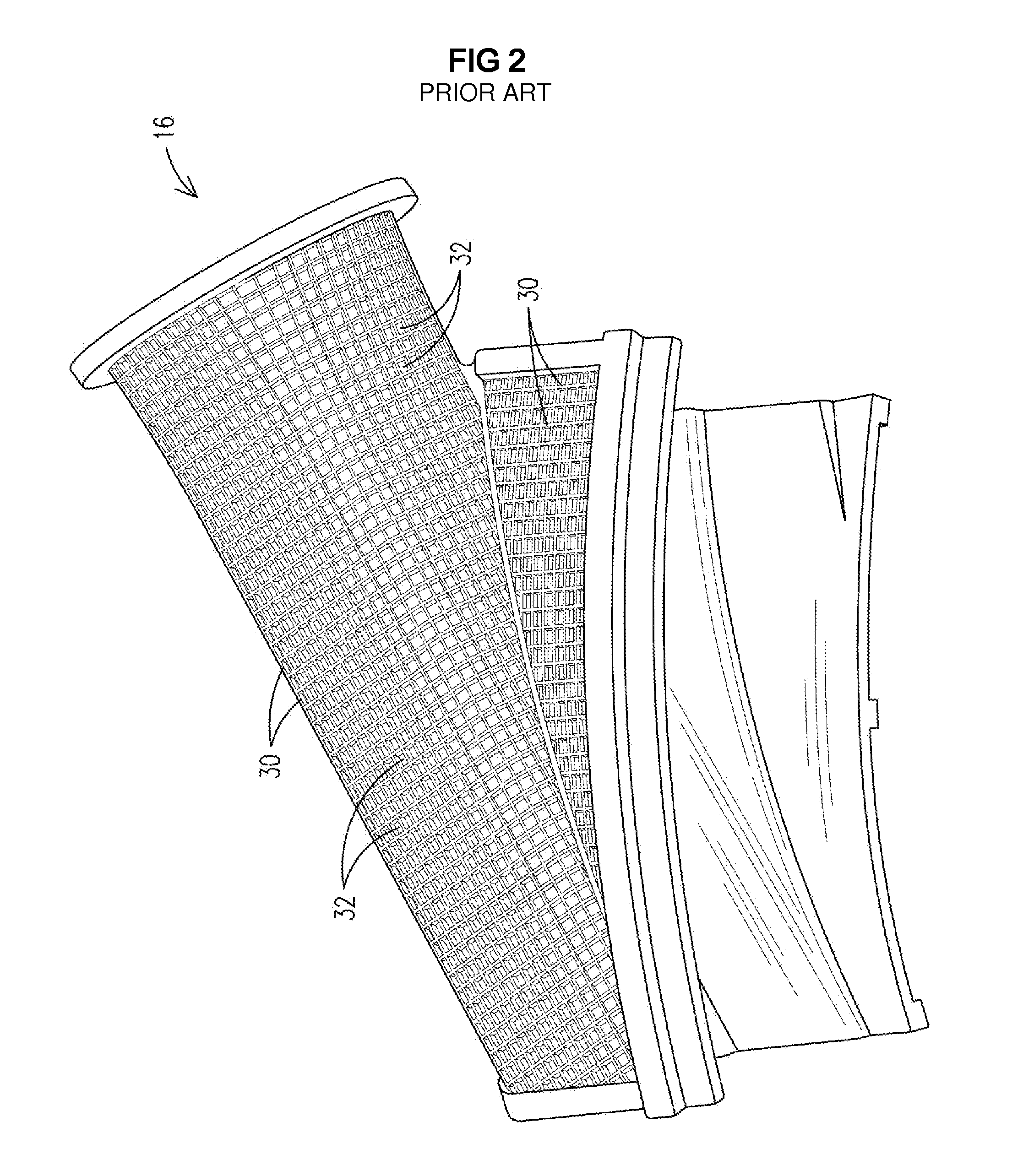

[0018]FIG. 1 shows an assembly 10 with a plurality of flow directing structures 12. Each flow directing structure 12 may include a cone 14 and an associated exit piece 16. Each cone 14 receives combustion gas 18 from a respective combustor (not shown), and begins accelerating the combustion gas 18 to a speed appropriate for delivery onto the first row of turbine blades (not shown). Acceleration of the combustion gas 18 is accomplished by an acceleration geometry 20 using flow cross section constriction based on the Bernoulli principle and the Venturi effect. In the example shown, this is embodied as a cone-shaped duct 14 with a centerline 25 oriented mainly tangentially and partly axially relative to the turbine axis 26. The cone 14 may abut the exit piece 16 at a joint 22. Adjacent exit pieces abut each other at joints 24. The exit pieces form an annular chamber immediately upstream of the first row of turbine blades (not shown). Combustion gas 18 enters each cone 14 and travels al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com