Laser sintering powder, method for producing structure, apparatus for producing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0110]Next, a second embodiment of the method for producing a structure according to the invention will be described.

[0111]Hereinafter, a second embodiment will be described, however, in the following description, different points from the first embodiment will be mainly described, and the description of the same matter will be omitted. Further, in the drawings, the same components as in the above-described embodiment will be given the same reference numerals.

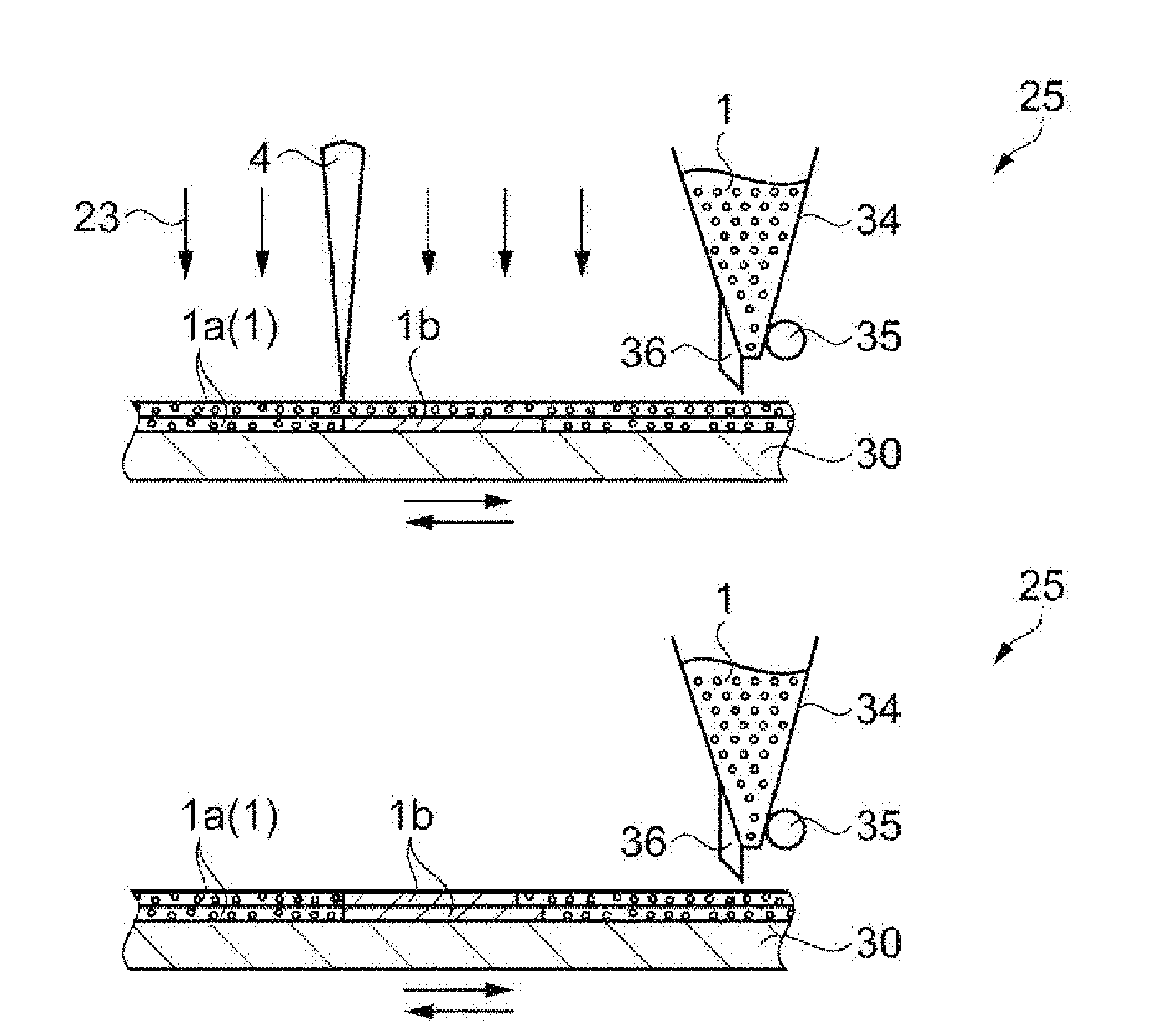

[0112]FIGS. 8A to 8F and FIGS. 9A to 9E are schematic views for explaining a method for forming a structure using a laser sintering powder (a second embodiment of the method for producing a structure according to the invention), respectively. Hereinafter, with reference to FIGS. 8A to 8F and FIGS. 9A to 9E, the method for forming a structure will be described. In this method, a laser sintering apparatus 25 (a second embodiment of the apparatus for producing a structure according to the invention) shown in FIG. 7 is used.

[0113]F...

third embodiment

[0133]Next, a third embodiment of the method for producing a structure according to the invention will be described.

[0134]Hereinafter, a third embodiment will be described, however, in the following description, different points from the second embodiment will be mainly described, and the description of the same matter will be omitted. Further, in the drawings, the same components as in the above-described embodiments will be given the same reference numerals.

[0135]FIGS. 10A to 10F and FIGS. 11A to 11E are schematic views for explaining a method for forming a structure using a laser sintering powder (a third embodiment of the method for producing a structure according to the invention), respectively. Hereinafter, with reference to FIGS. 10A to 10F and FIGS. 11A to 11E, the method for forming a structure will be described. Also in this method, the laser sintering apparatus 25 shown in FIG. 7 is used.

[0136]The third embodiment is the same as the second embodiment except that the timin...

modification example 1

[0179]In the embodiments described above, the powder layer 1a is sintered by irradiating the powder layer 1a with the laser light 4. However, the sintered layer 1b may be further heated. By doing this, a structure 49 having high peeling resistance strength can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com