Process for producing a highly transparent impact-resistant glass ceramic

a technology of impact-resistant glass and ceramics, which is applied in the direction of chemistry apparatus and processes, weapons, protective equipment, etc., can solve the problems of interference fringe patterns, time-consuming and cost-intensive linkage of individual layers and plastic materials to each other, and the inherent color of transparent glass ceramics is too strong, etc., to achieve high bullet penetration resistance, high transparency, and high resistance to bullet penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

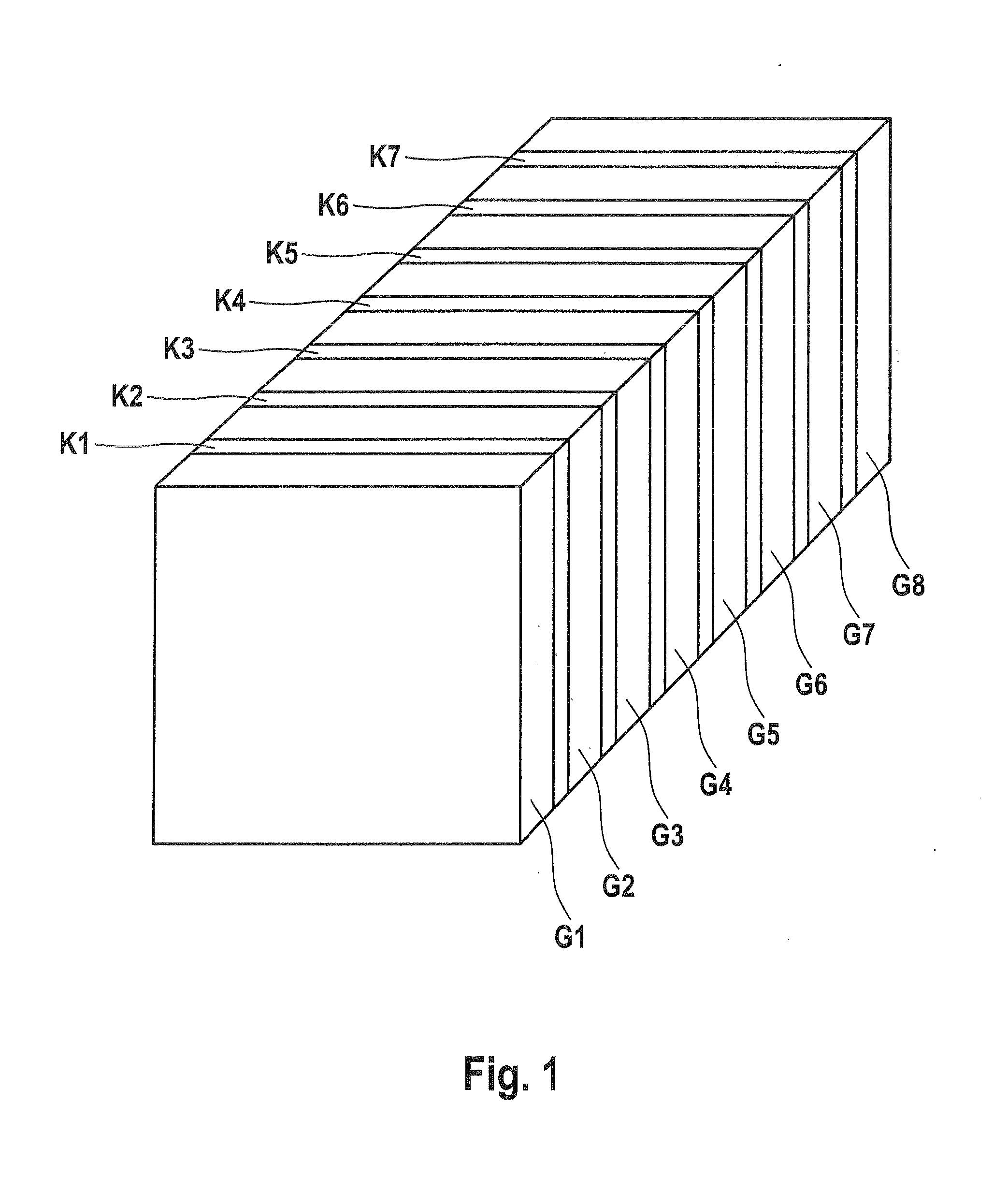

Image

Examples

examples

[0073]Four different glass ceramics of different composition, examples 1 to 4 in Table 1 here below, were prepared (data are given in wt. % based on oxides). The brightness value YA,2° Is GIVEN for a glass thickness of 4 mm and the linear thermal expansion coefficient (CTE) is given for the range between 30 and 700° C. The linear thermal expansion coefficient CTE was determined in the 30 to 700° C. temperature range in accordance with DIN ISO 7991 by use of a Thermal Dilatometric Analyzer, Harrop Model TD 710.

[0074]To prepare the glass ceramics, first a green glass of the same composition was prepared in the usual manner. From this green glass, glass plates of the desired thickness were then made. The glass plates were then ceramized in the known manner to form glass ceramic plates, the nucleating agents having been formed in the glass at a temperature of 750° C. and a residence time of 20 minutes. The glass was then heated to the crystallization temperature of 830° C. The crystalli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com