Dual Diaphragm Electrolysis cell assembly and method for generating a cleaning solution without any salt residues and simultaneously generating a sanitizing solution having a predetermined level of available free chlorine and PH

a technology of diaphragm electrolysis and assembly method, which is applied in the direction of electrolysis components, water/sludge/sewage treatment, chemistry apparatus and processes, etc., can solve the problems that the cathode water is not necessarily suitable for actual cleaning or surface treatment, and the anode water is not necessarily suitable for sanitizing hard surfaces. to achieve the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

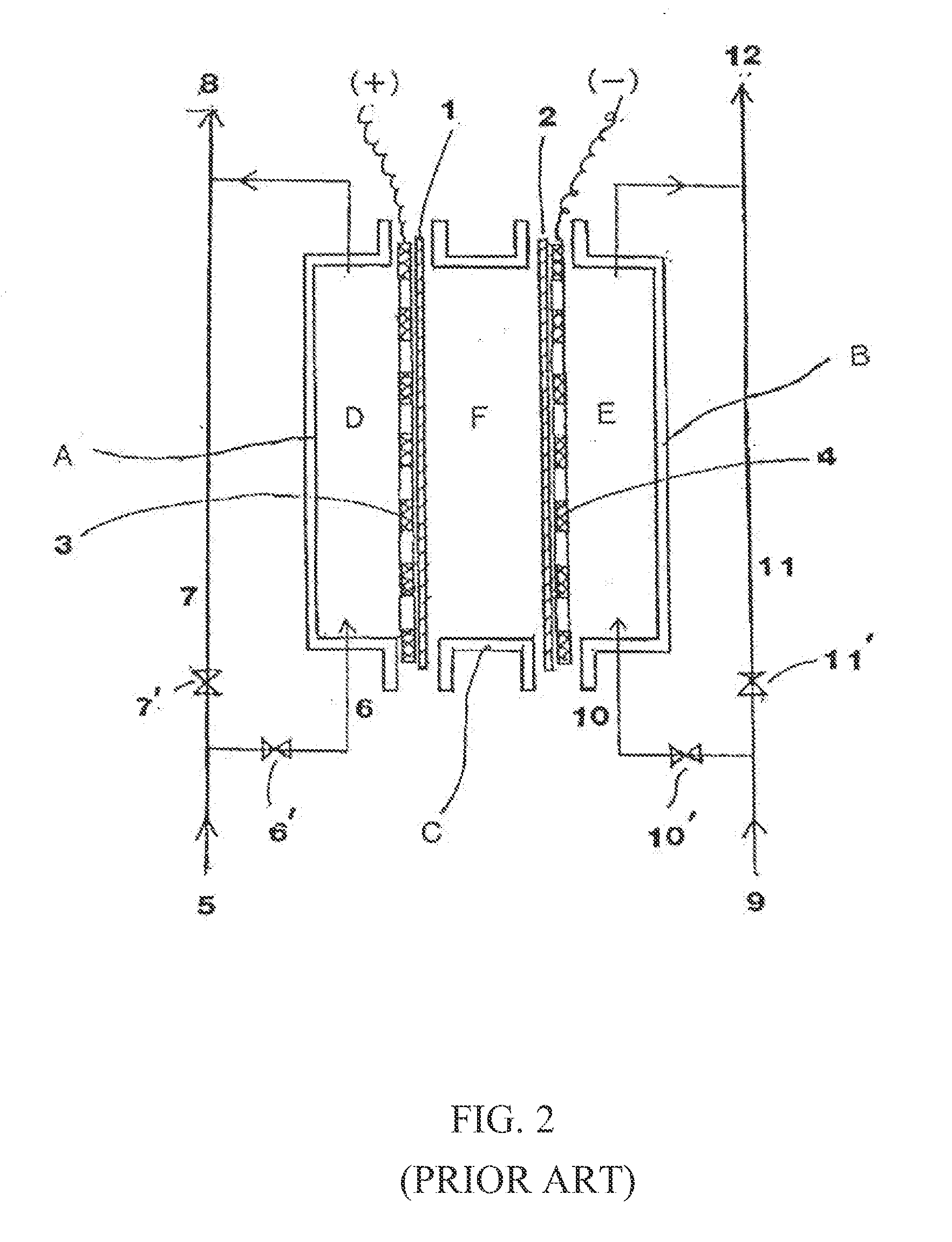

[0081]The present invention is directed to the construction of an optimized cylindrical electrolysis cell that produces a cleaning solution and simultaneously a sanitizing solution. The diluted Sodium Hydroxide solution is more alkaline, contains no salt residues and, therefore, the solutions can be used to clean any surface without rinsing the surface afterwards with distilled, RO water or tap water. The diluted Hypochlorous Acid solution contains no salt residues and its free available chlorine content as well as pH can be adjusted. As a result, surfaces can be effectively sanitized using a sanitizing solution which pH and free available chlorine is ‘tailored’ to sanitize a certain surface taking into account chlorine consumption and in line with various sanitizing procedures as set by regulatory agencies such as the FDA, EPA, USDA and CDC. Certain surfaces require a more acidic sanitizer whereas other surfaces are damaged by the acid nature of the sanitizer. In these cases, a mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com