Rail cum road vehicles (RCRV) and economy rail track-cum-corrugated concrete track to engage with corrugated tread rubber wheels on all roadways.

a technology of cum road vehicles and corrugated concrete, which is applied in the direction of locomotives, retractable wheels, transportation and packaging, etc., can solve the problems of high construction cost of rail tracks, inability to accommodate more passenger coaches or wagons, and inability to meet the needs of such costly rail net work in all developing and poor countries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

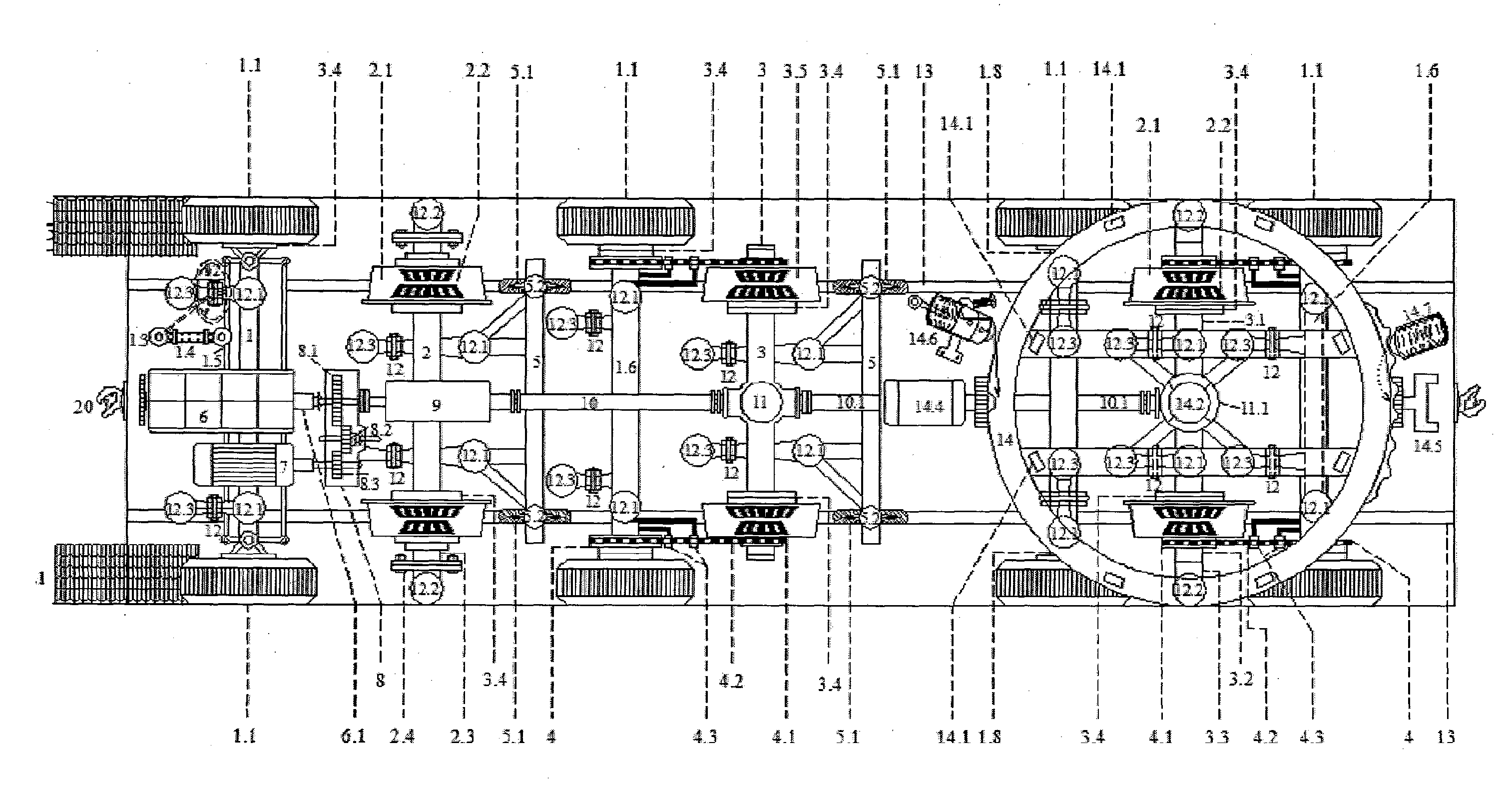

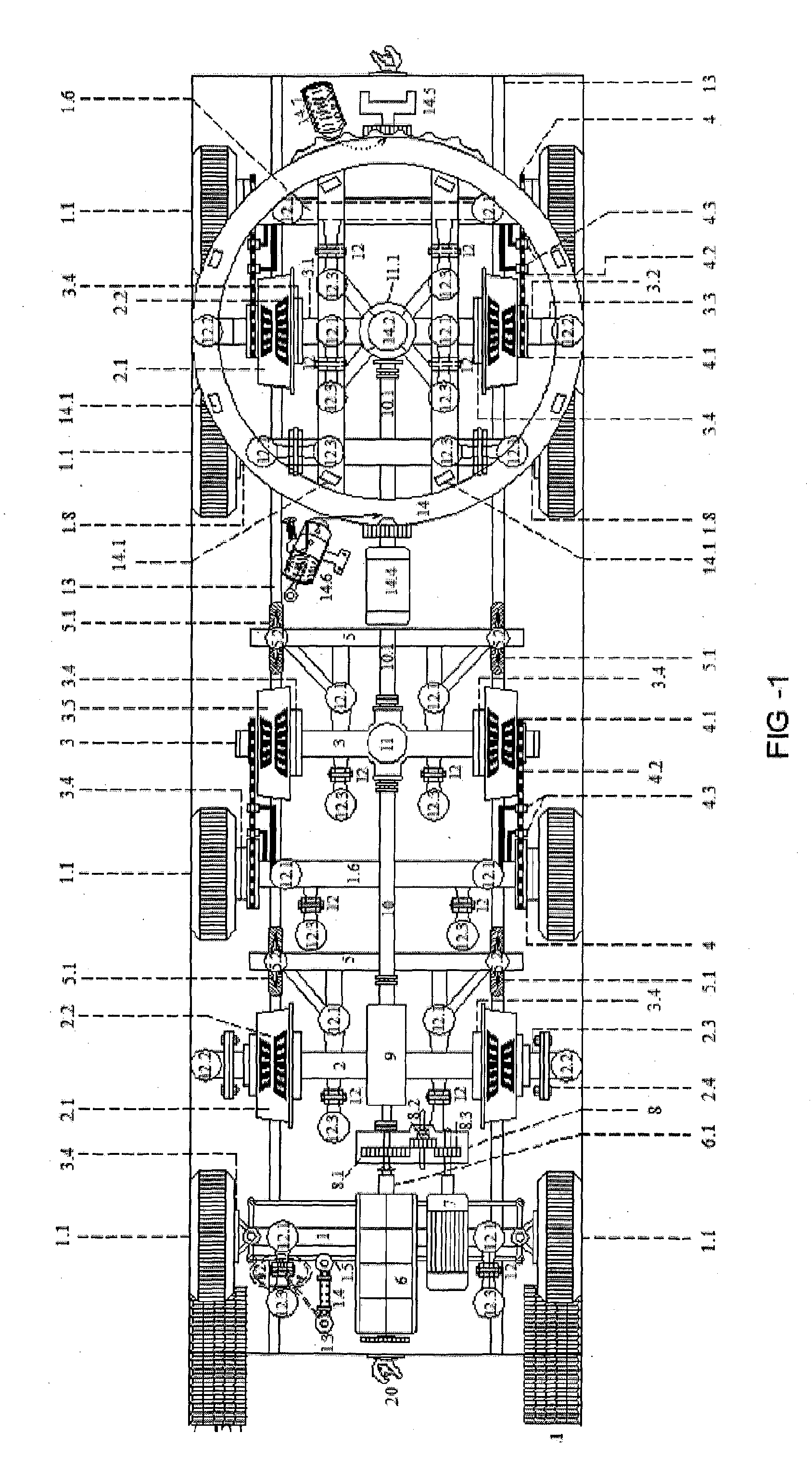

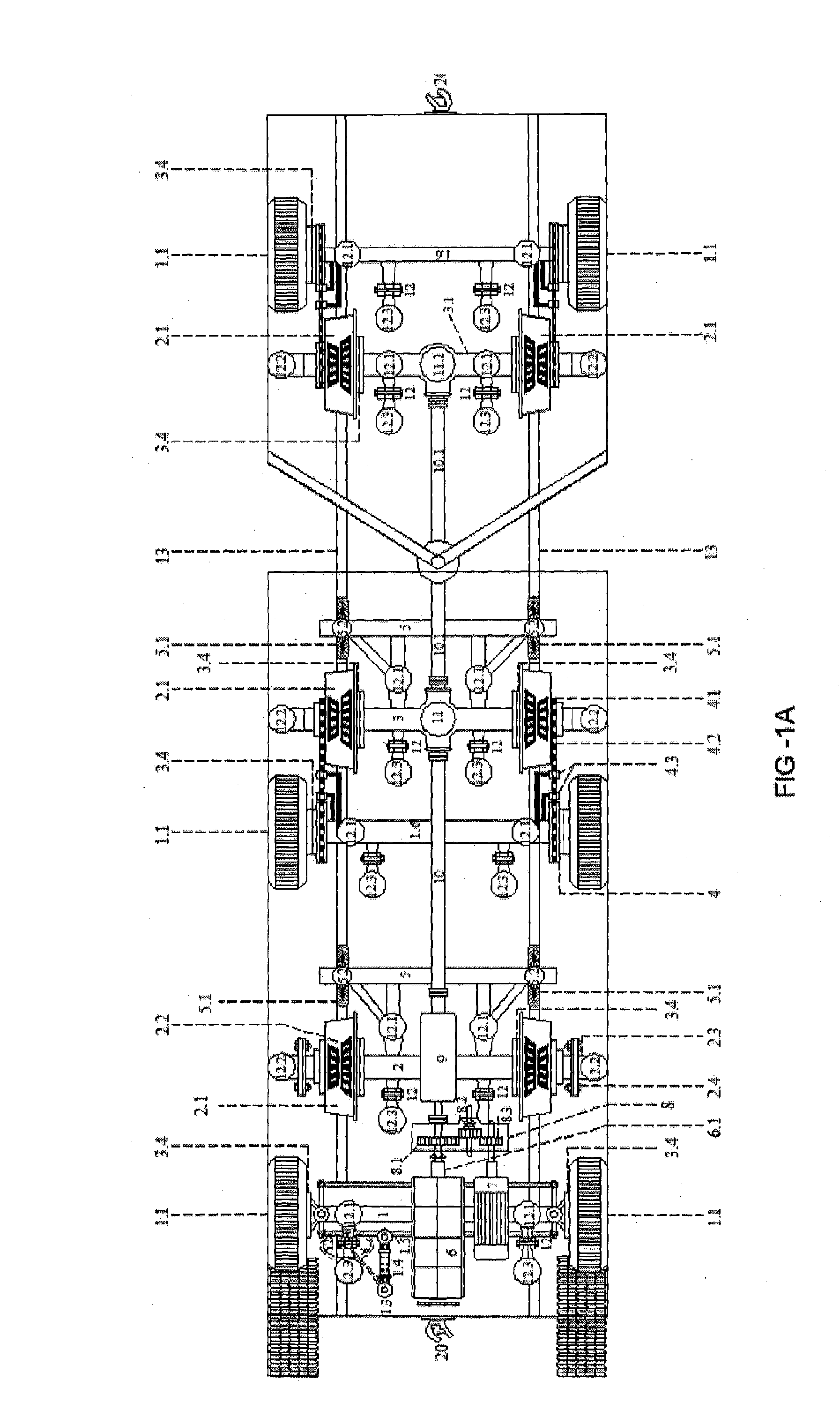

[0086]The FIG. 1 is a Rail cum Road Vehicle of the invention being a “Hybrid Engine Coach” totally an independent prime mover on rails or on all roadways. It has 4 pairs of rubber wheels 1.1 and 2 pairs of flanged steel wheels 2.1 and one pair of FLANGELESS steel wheels 3.5. The solid axle 1 is the front axle with normal size rubber wheels 1.1 and controlled by steering and pinion 1.3 which is connected to steering end arm 1.4 and tied to the tie rod 1.5.

[0087]Solid axle 2 with flanged steel wheels 2.1 fitted with taper roller bearings 2.2 supported by threaded bush with end flange 2.3 to hold steel wheel 2.1. To prevent loosening or tightening of the threaded bush 2.3, a square holed bush with flange 2.4 is bolted to the flange of the threaded bush 2.3. This square bush also hold the air bag 12.2 on it at solid steel wheel axle's both the ends. Crowned hollow axle with flanged steel wheels is fitted with axle's end flange with long bush 2.5 and overlaid square bush 2.6. In between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com