Construction Machine

a construction machine and connector technology, applied in the direction of machines/engines, mechanical equipment, transportation and packaging, etc., can solve the problems of affecting the operation of the construction machine, the difference of elevation between and the discharge pressure of the urea water supply device to the urea water injection valve could vary significantly, so as to achieve the effect of effective use of the connection frame, favorable warming, and promotion of defrosting of ur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

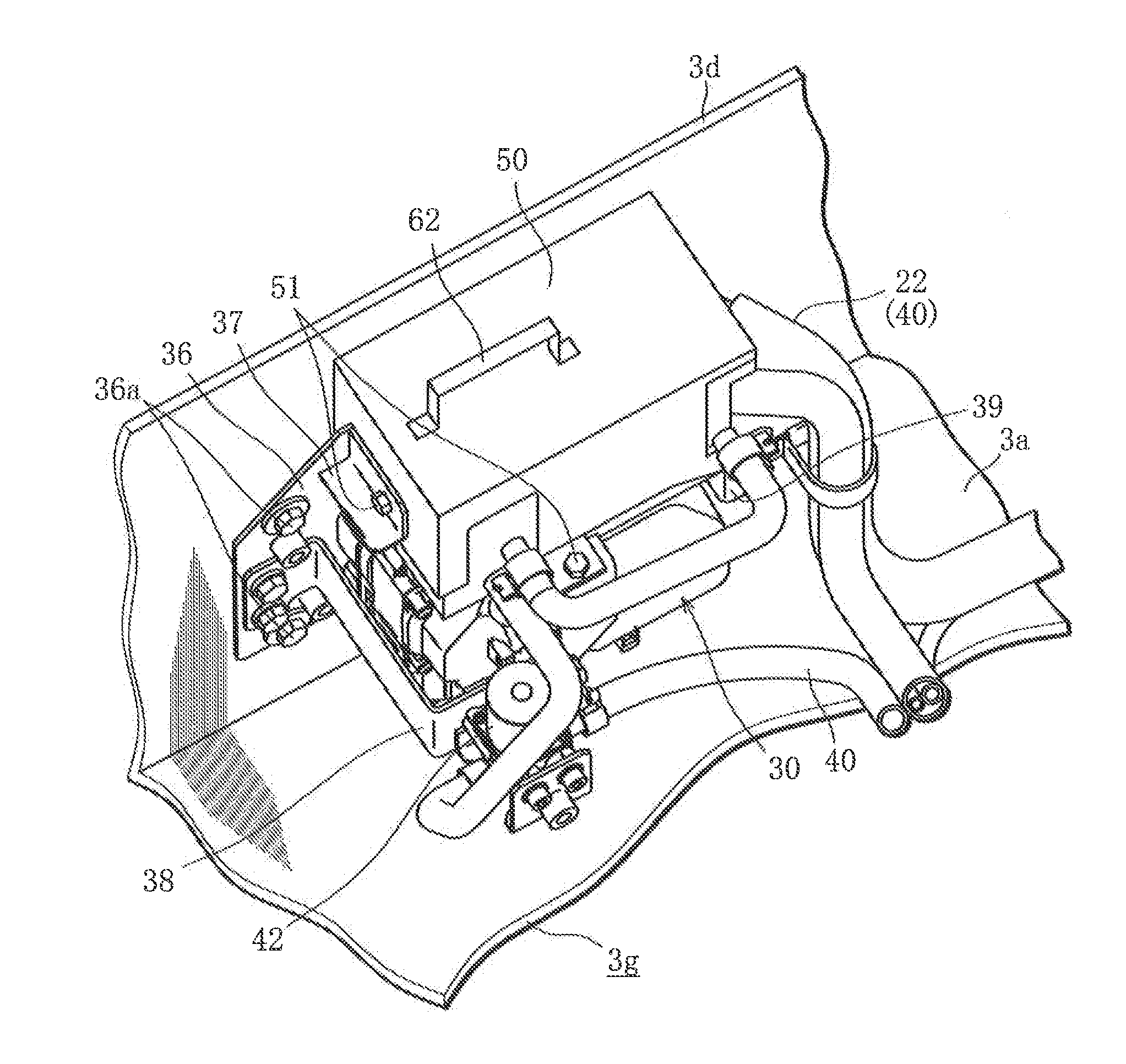

[0038]Hereinafter, one embodiment of a construction machine according to the present invention will be described based on the drawings.

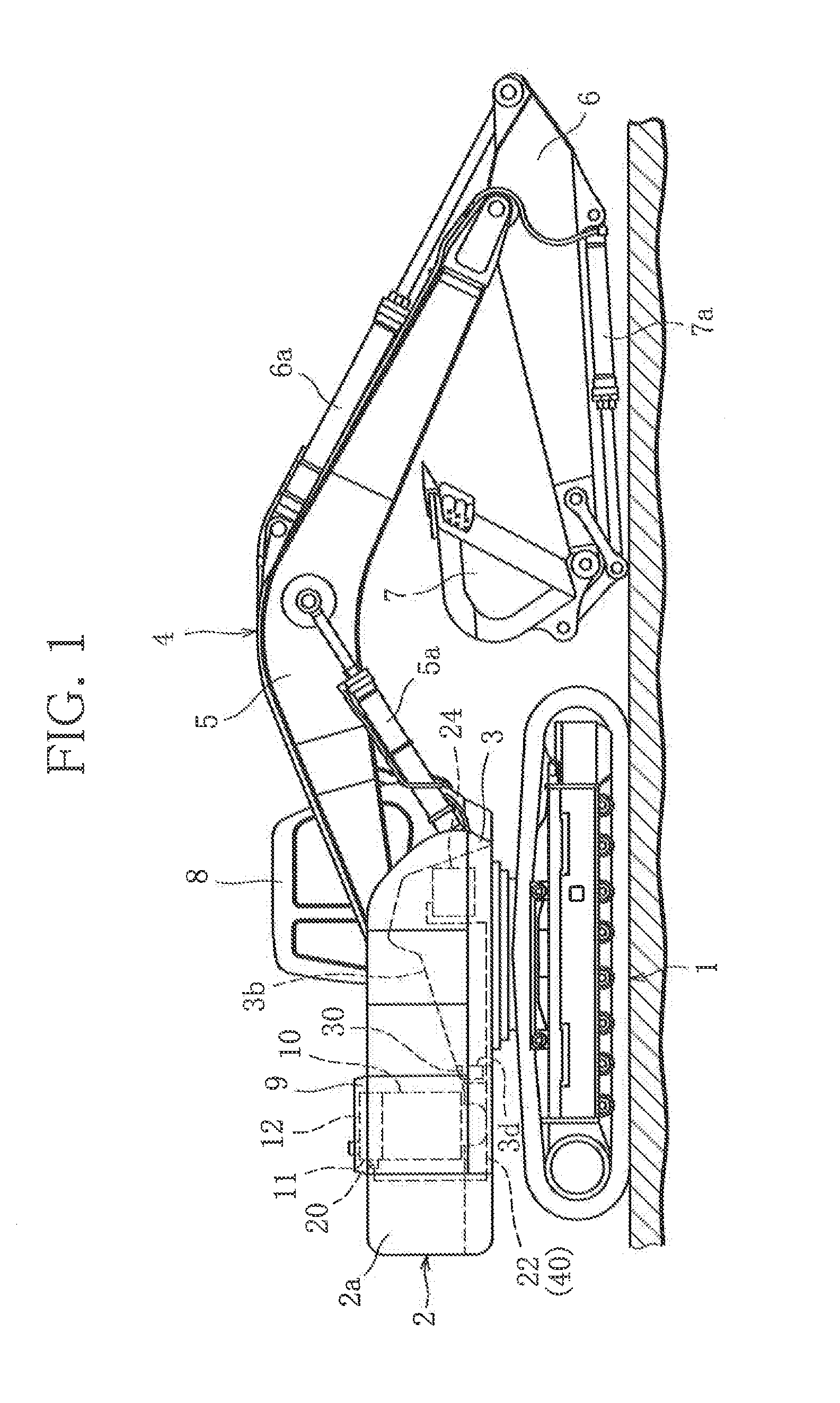

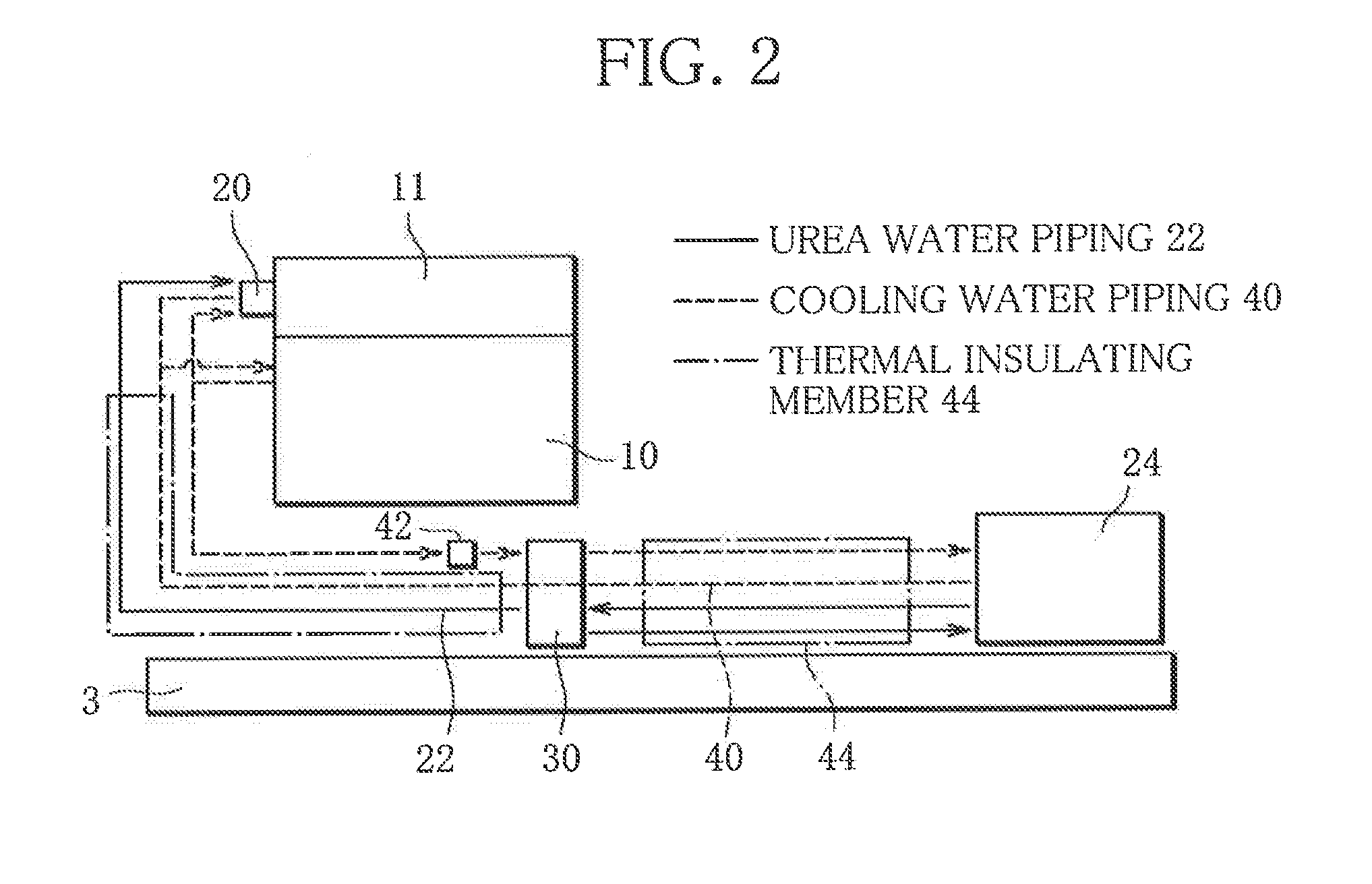

[0039]FIG. 1 shows the construction machine including a urea water supply system according to the present invention. In the present embodiment, as the construction machine, a crawler type hydraulic shovel will be described by being cited as an example.

[0040]As shown in FIG. 1, the hydraulic shovel is constructed by including a traveling structure 1, a revolving superstructure 2 that is disposed on the traveling structure 1 and is mainly constituted of a revolving frame 3, and a working device 4 that is mounted to the revolving superstructure 2 and performs excavating work of earth and sand, and the like.

[0041]The working device 4 is constructed by including a boom 5 that is mounted to the revolving frame 3 rotatably in a vertical direction, an arm 6 that is mounted to a tip end of the boom 5 rotatably in the vertical direction, and a bucket 7 that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com