Thermally expandable resin composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

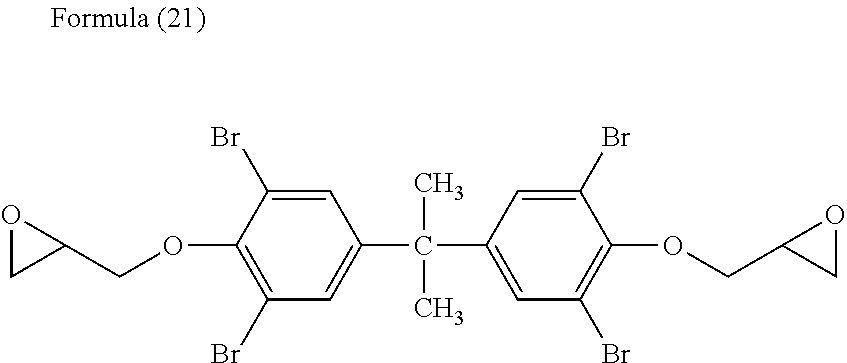

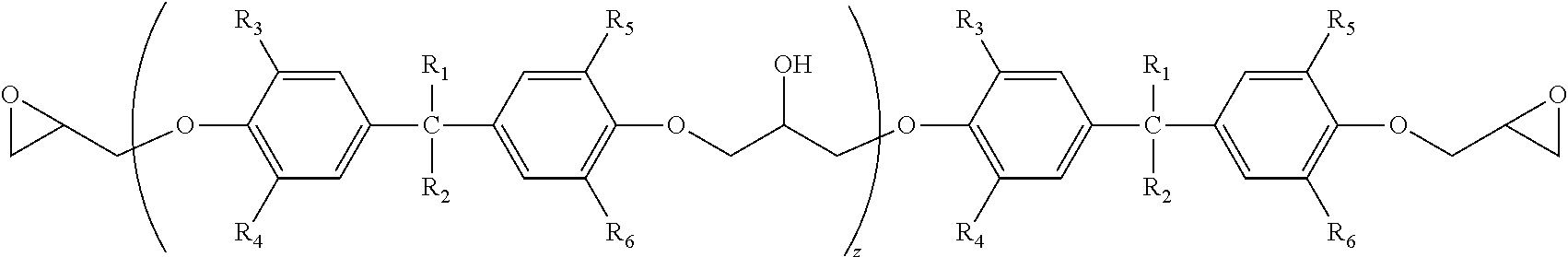

[0163][(Z) A Combination of Said Brominated Epoxy Epoxy Compound and at Least One of a Bisphenol-Type Epoxy Compound and an Aliphatic Epoxy Compound]

[0164](X is a repeating unit ranging from 1 to 100.)

[0165]10.9 parts by weight of tetrabromobisphenol-A-diglycidyl-ether (available from Nippon Steel Chemical Co., Ltd., trade name: YDB-400, an epoxy equivalent: 403.1 g / eq. Hereinafter referred to as “A-10”.) as the (Z-1),

[0166]45.4 parts by weight of bisphenol-F-diglycidyl-ether (available from Mitsubishi Chemical Corporation, trade name: E807, an epoxy equivalent: 168 g / eq. Hereinafter referred to as “A-1”.) as the (Z-3),

[0167]43.7 parts by weight of an amino compound which is prepared by mixing 3-lauryloxypropyl-1-amine with hexamethylenediamine derivative (available from Mitsubishi Chemical Corporation, trade name: FL052) at a weight ratio of 6:4 (an amine equivalent: 167.3 g / eq., on the basis of the active hydrogen. Hereinafter referred to as “B-1”.), as an epoxy curing agent, 90 p...

example 2

[0186]In the case of Example 1, 11.2 parts by weight of “A-10” are used, 39.3 parts by weight of “A-1” are used. Also, in addition to “A-10” and “A-1”, the (Z-6) is used.

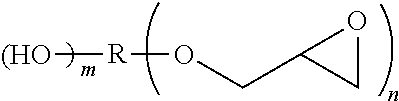

[0187](R7 is an alkylene group having 1 to 20 carbon atoms, alkenylene group having 1 to 20 carbon atoms or arylene group having 1 to 20 carbon atoms.)

[0188]As the (Z-6), 4.7 parts by weight of dimer-modified epoxy (an epoxy equivalent: 422 g / eq. Hereinafter referred to as “A-3”.) are used.

[0189]Also, 43.9 parts by weight of “B-1” are used. The formulation used in Example 2 and the results are shown in Table 1.

example 3

[0190]In the case of Example 1, 31.6 parts by weight of “A-10” are used; the (Z-5) is used instead of “A-1”.

[0191]As the (Z-5), 31.5 parts by weight of hexamethylene diglycidyl ether (an epoxy equivalent: 157 g / eq. Hereinafter referred to as “A-2”.)

[0192]Also, completely the same experiment as in Example 1 is carried out, except that 36.9 parts by weight of “B-1” are used.

[0193]The formulation used in Example 3 and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com