Pwm rectifier including capacitance calculation unit

a capacitance calculation and rectifier technology, applied in resistance/reactance/impedence, power supply testing, instruments, etc., can solve the problems of harmonics or reactive power of power lines, ripple current flowing through dc links, increasing dc voltage fluctuation, etc., to achieve accurate measurement of the capacitance of smoothing capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]A PWM rectifier including a capacitance calculation unit will be described below with reference to the accompanying drawings. However, it should be understood that the present invention is not limited to the drawings or embodiments which will be described below.

[0031]In the following description, a case in which a PWM rectifier is disposed in a motor control device which is connected to an inverter through a DC link having a smoothing capacitor will be described as an embodiment. However, the PWM rectifier is not particularly limited to use as a rectifier in a motor control device, and the PWM rectifier may be applied to any device that has a configuration in which a PWM rectifier and an inverter are connected through a DC link having a smoothing capacitor. A load connected to the configuration is also not particularly limited to a motor.

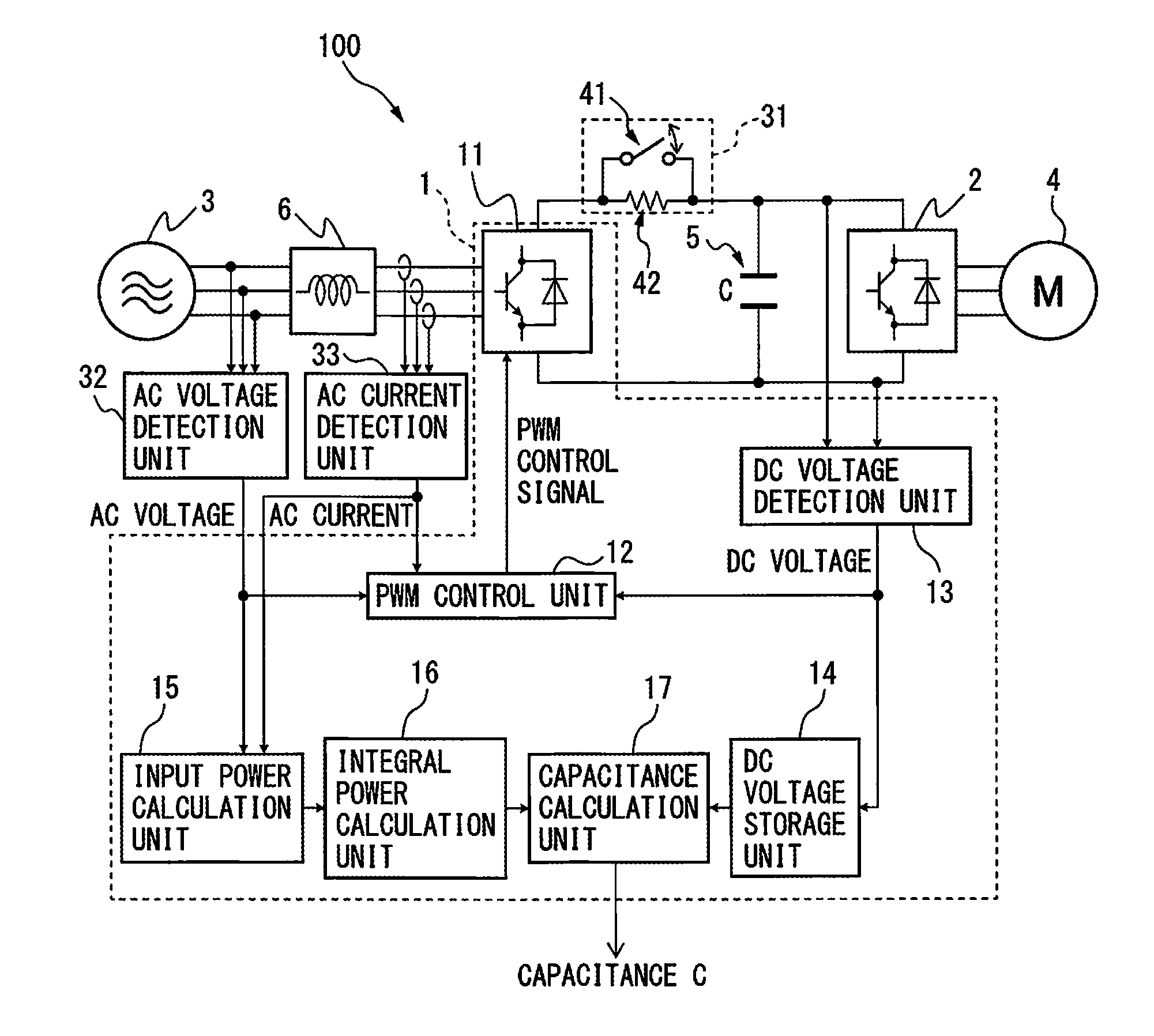

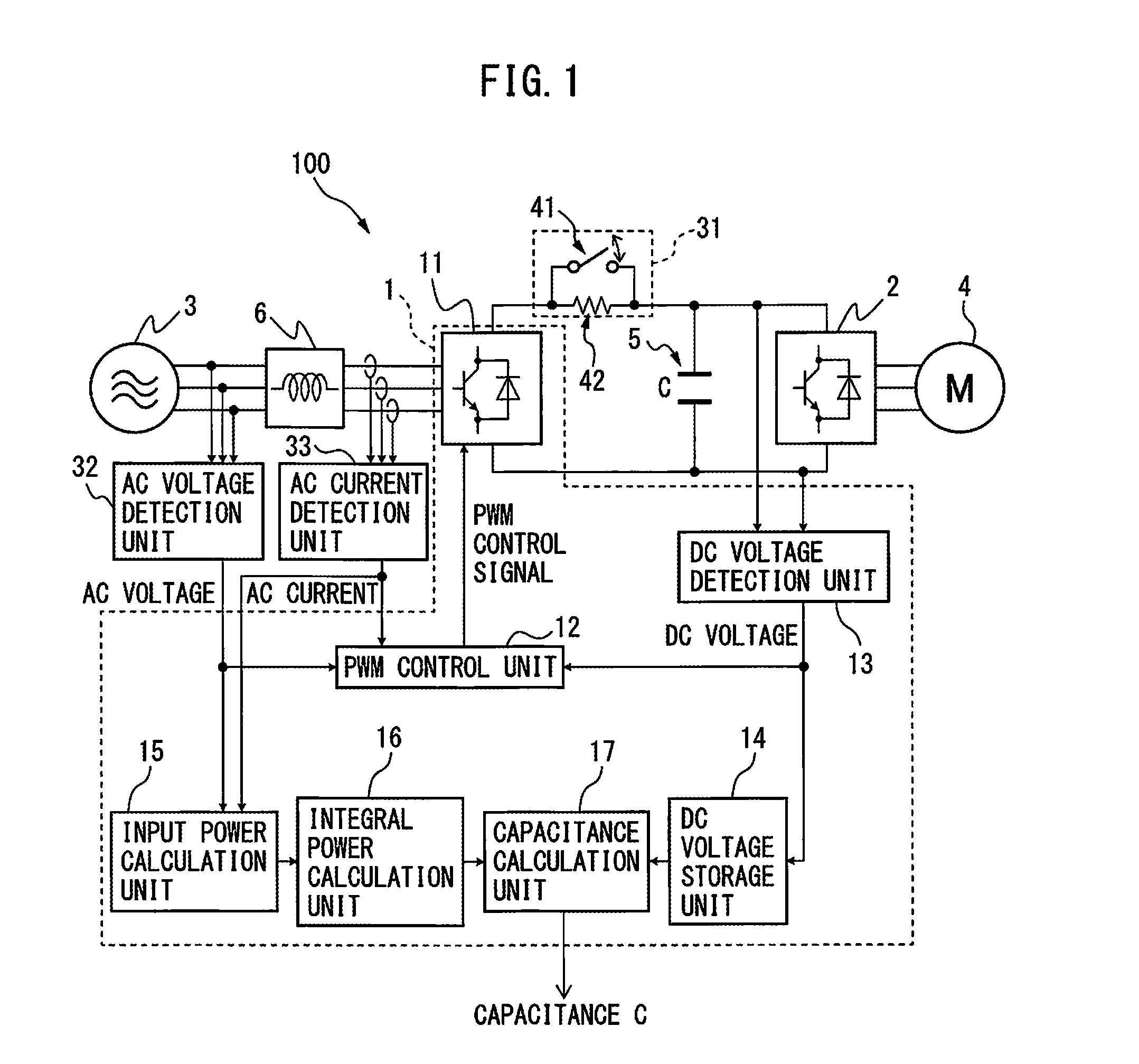

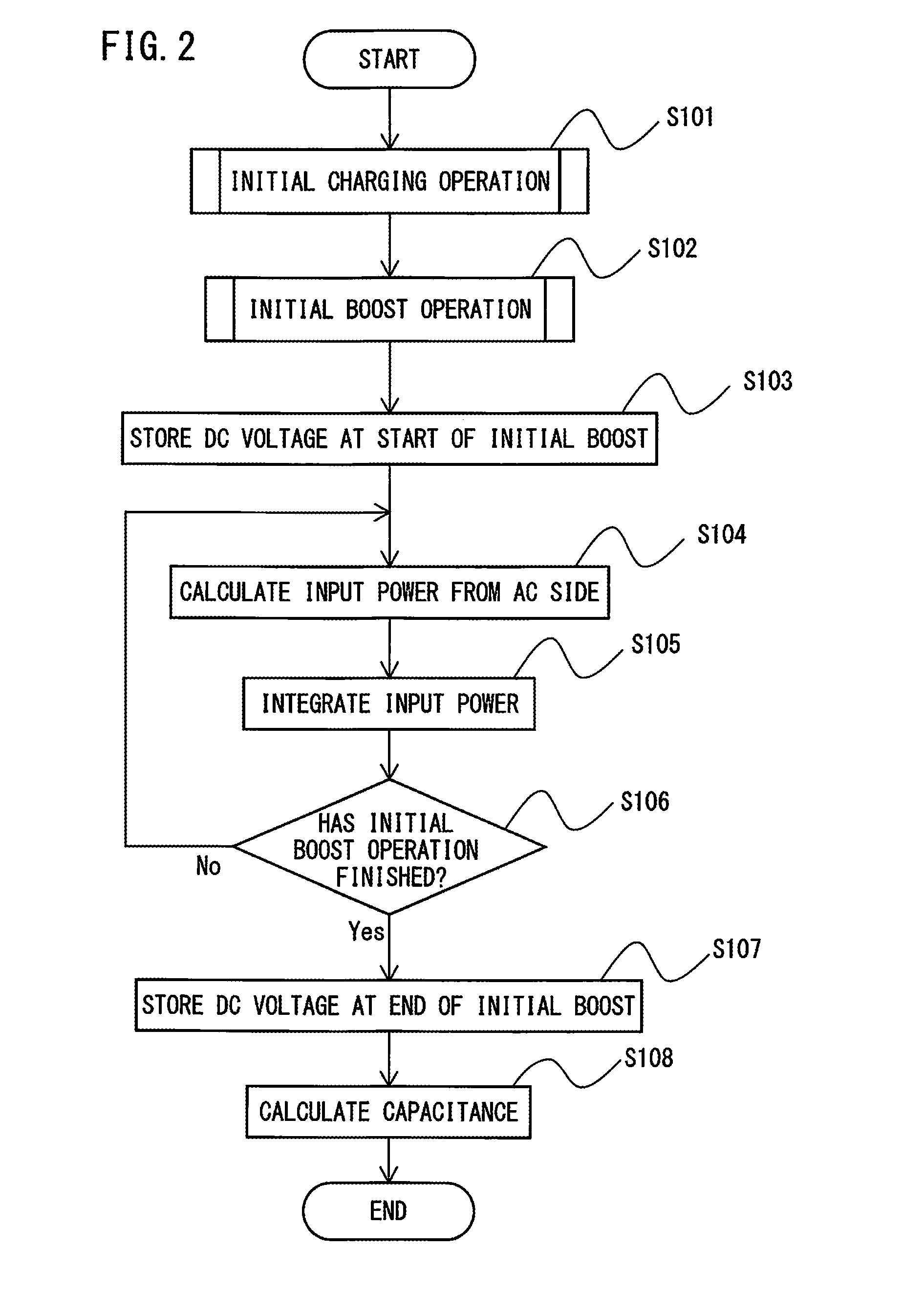

[0032]FIG. 1 is a principle block diagram illustrating a PWM rectifier according to an embodiment. A motor control device 100 includes a PWM ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com