Semiconductor structure having a center dummy region

a technology of dummy region and semiconductor, which is applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problem that current planar fets no longer meet the requirements of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]To provide a better understanding of the presented invention, preferred embodiments will be made in detail. The preferred embodiments of the present invention are illustrated in the accompanying drawings with numbered elements.

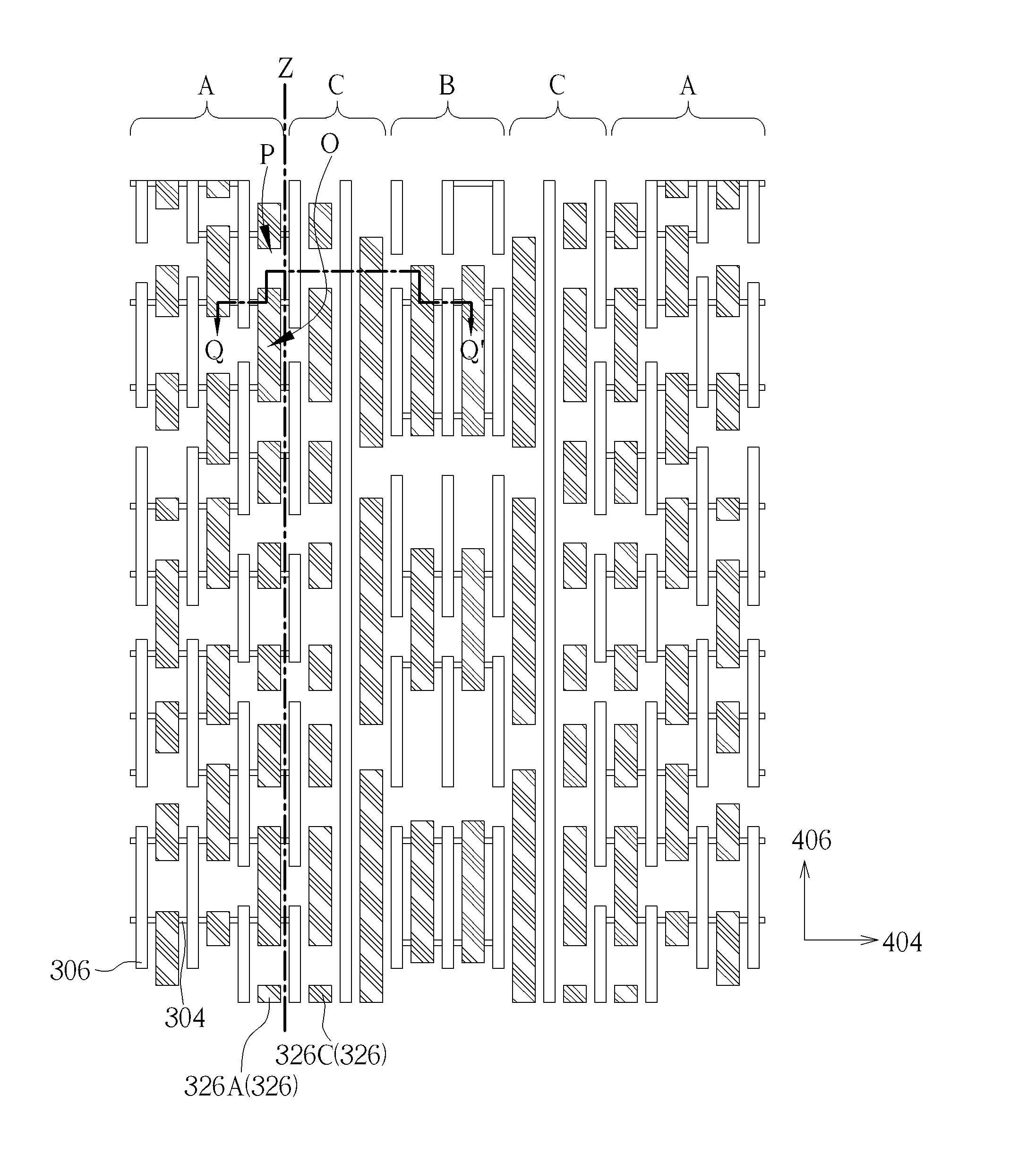

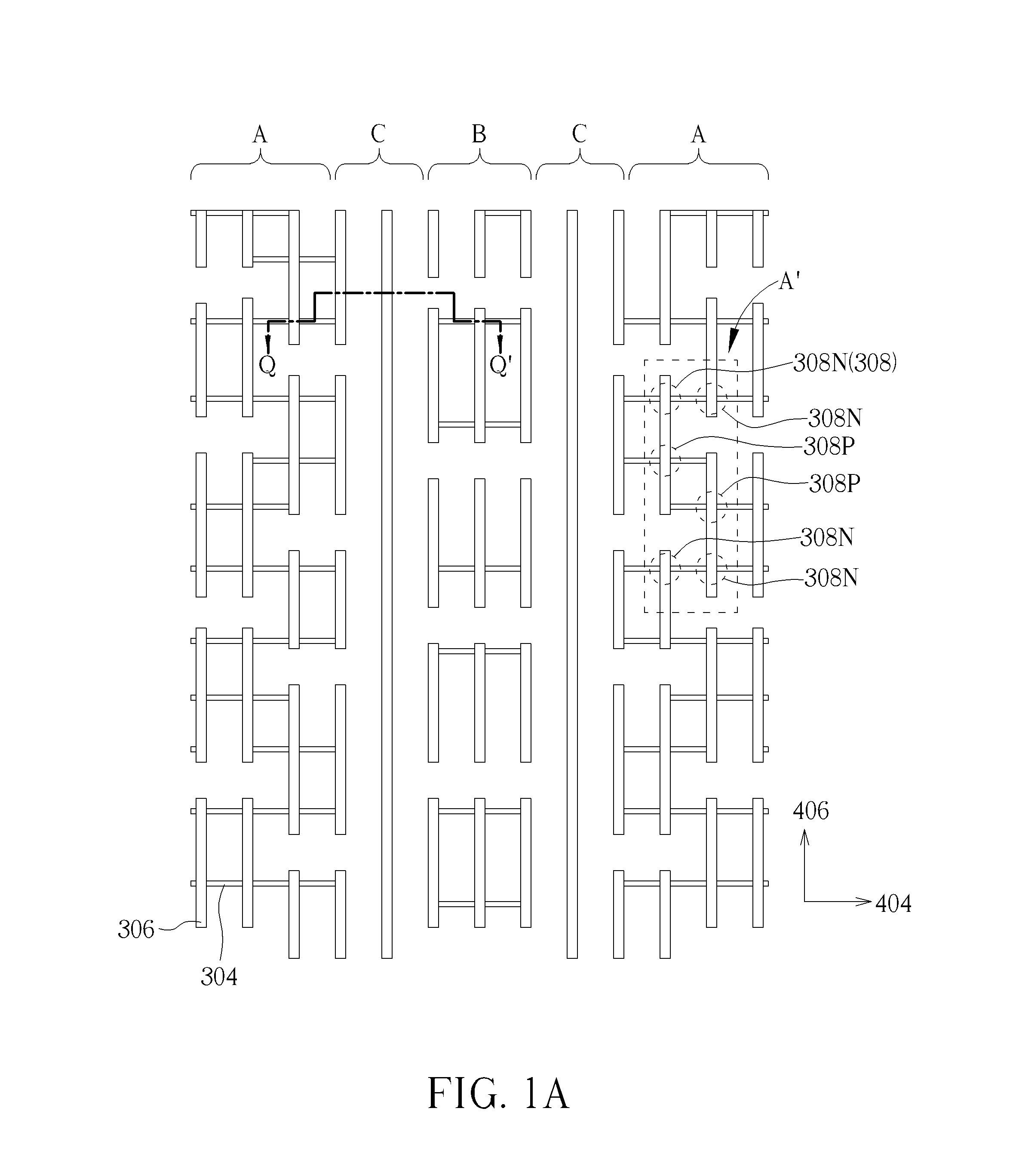

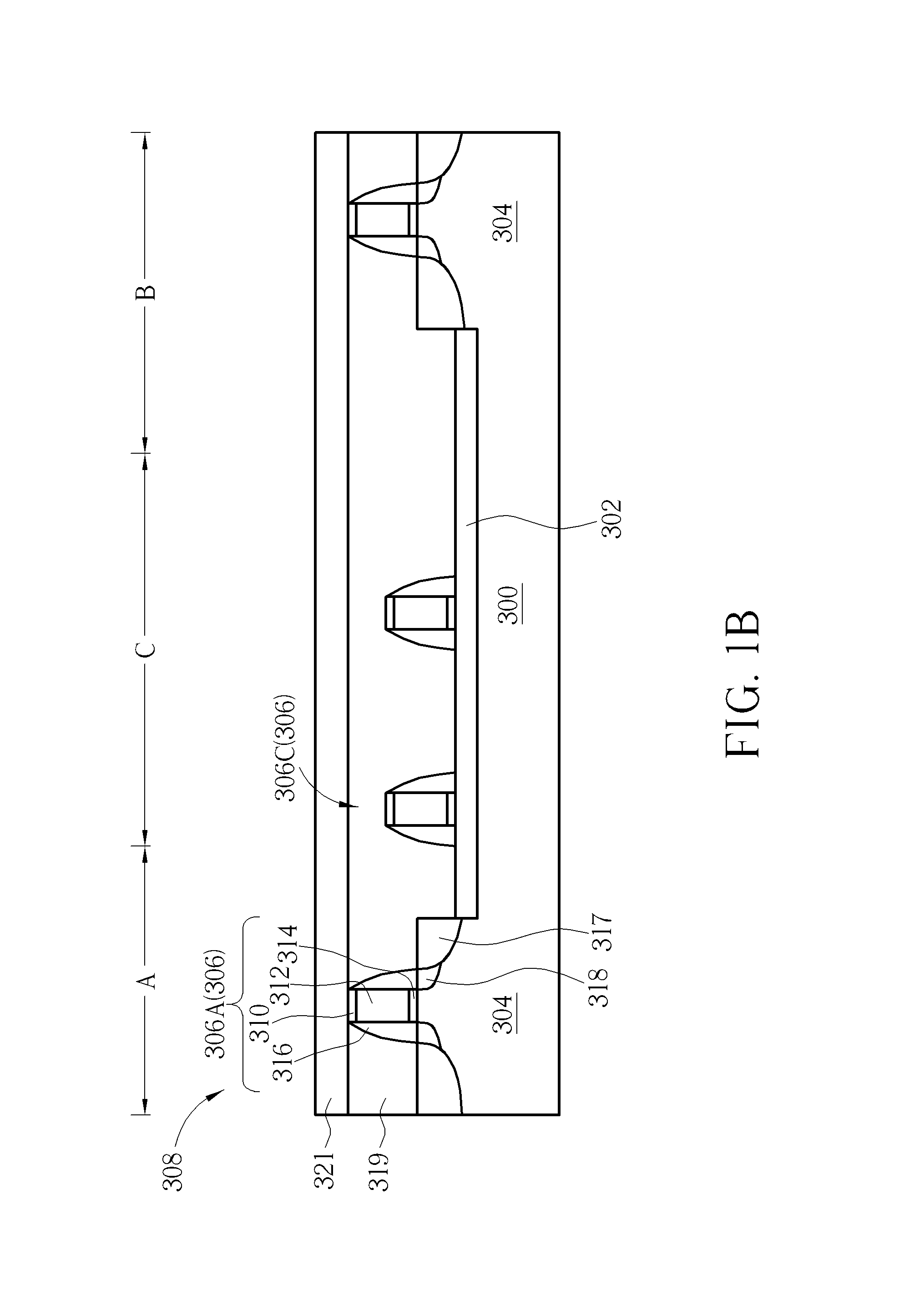

[0017]Please see FIG. 1A, FIG. 1B, FIG. 2A, FIG. 2B, FIG. 3A, FIG. 3B, FIG. 4A and FIG. 4B showing schematic diagrams of the semiconductor structure and method for forming the same according to the first embodiment of the present invention, wherein FIG. 1A, FIG. 2A, FIG. 3A, FIG. 4A are top view, and FIG. 1B, FIG. 2B, FIG. 3B, FIG. 4B are cross-sectional view taken along line QQ′ of FIG. 1A, FIG. 2A, FIG. 3A, FIG. 4A, FIG. 5A, respectively.

[0018]Please see FIG. 1A and FIG. 1B first. A substrate 300 is provided to serve as a base for forming devices, components, or circuits. The substrate 300 is preferably composed of a silicon containing material. Silicon containing materials include, but are not limited to, Si, single crystal Si, polycrystalline Si, SiG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com