Electric Oil Pump

a technology of electric oil pump and electric motor, which is applied in the direction of liquid fuel engines, rotary/oscillating piston pump components, machines/engines, etc., can solve the problems of short breakage, and affecting the heat resistance of the oil cooler. , to achieve the effect of improving the heat resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

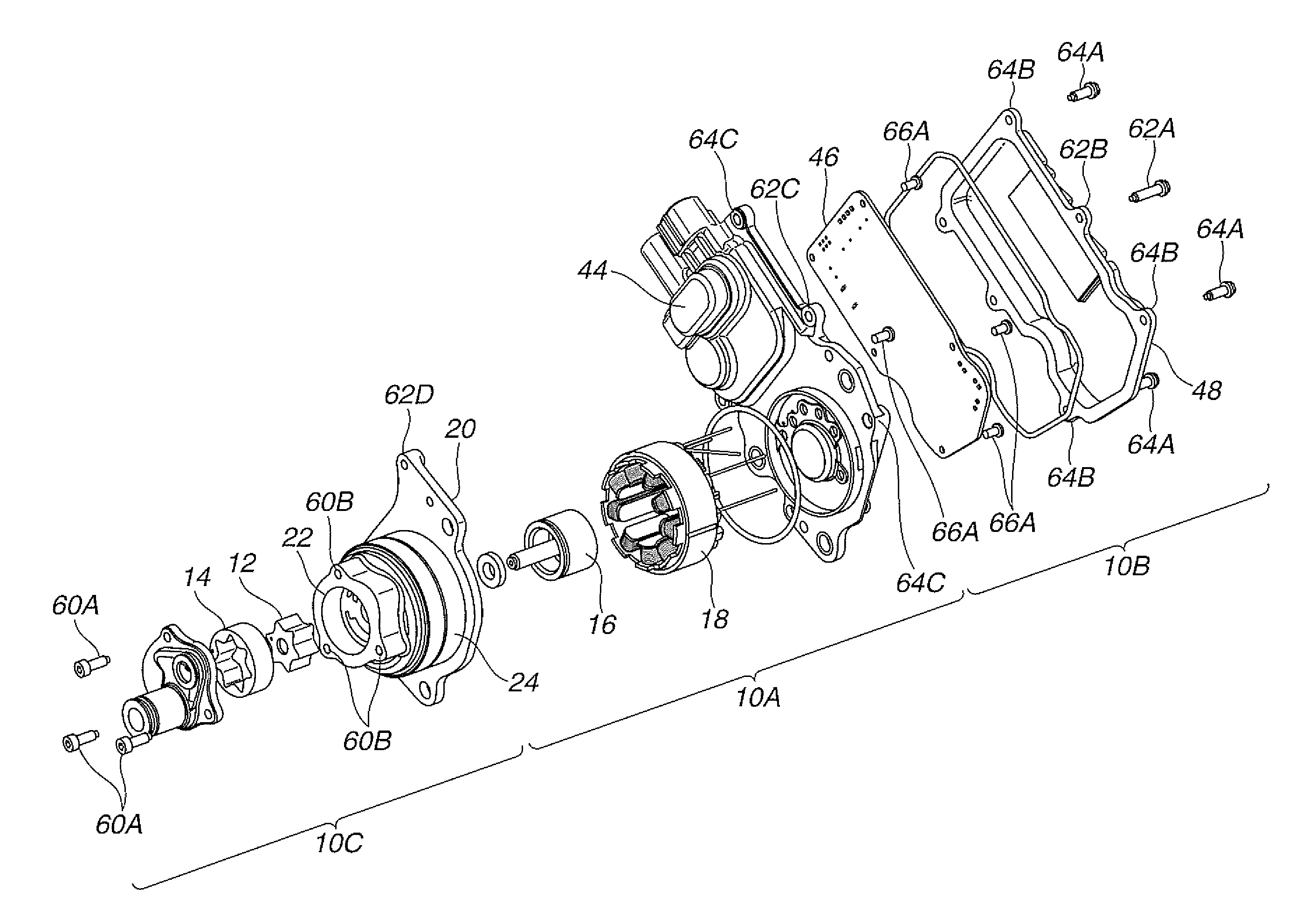

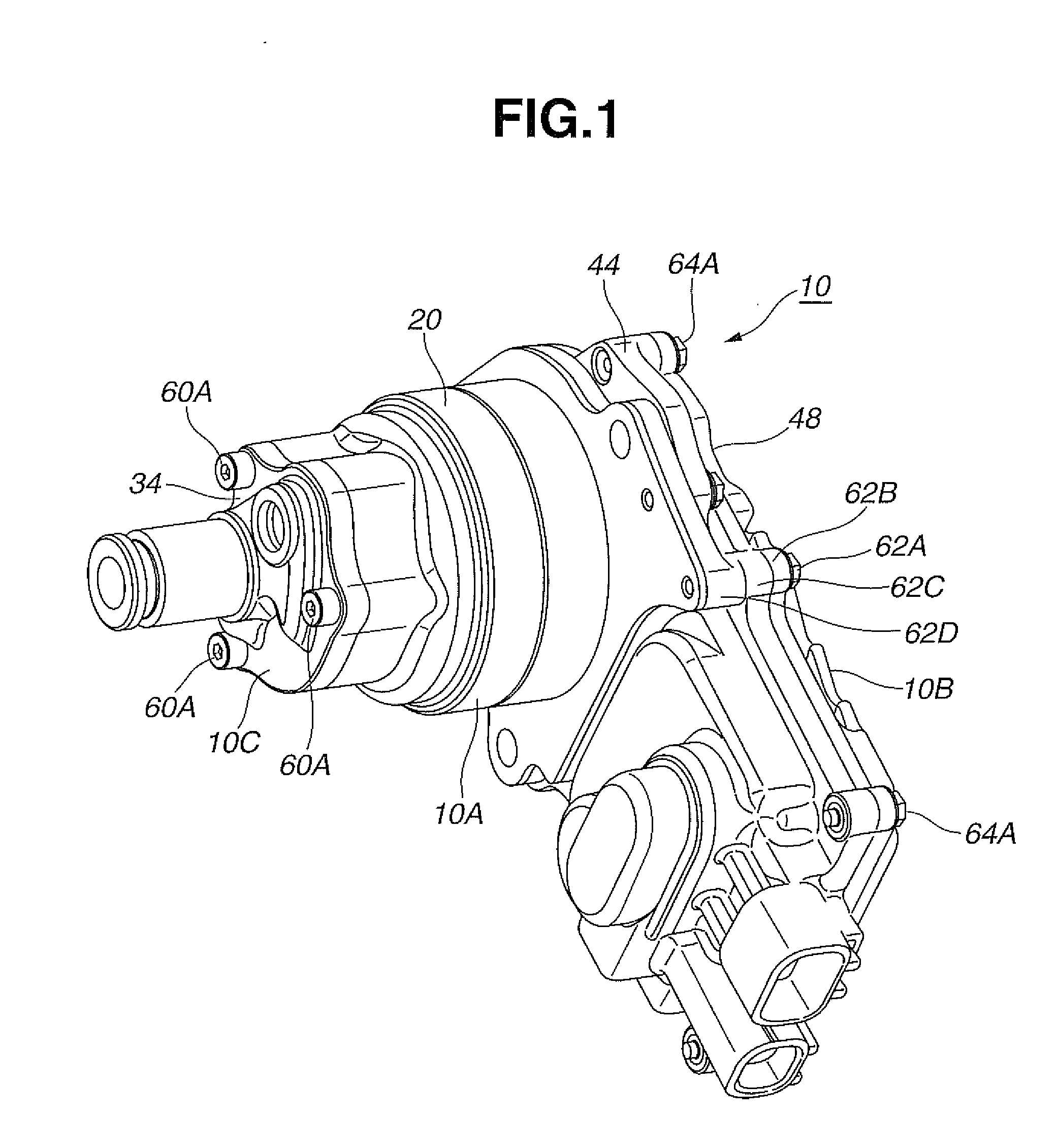

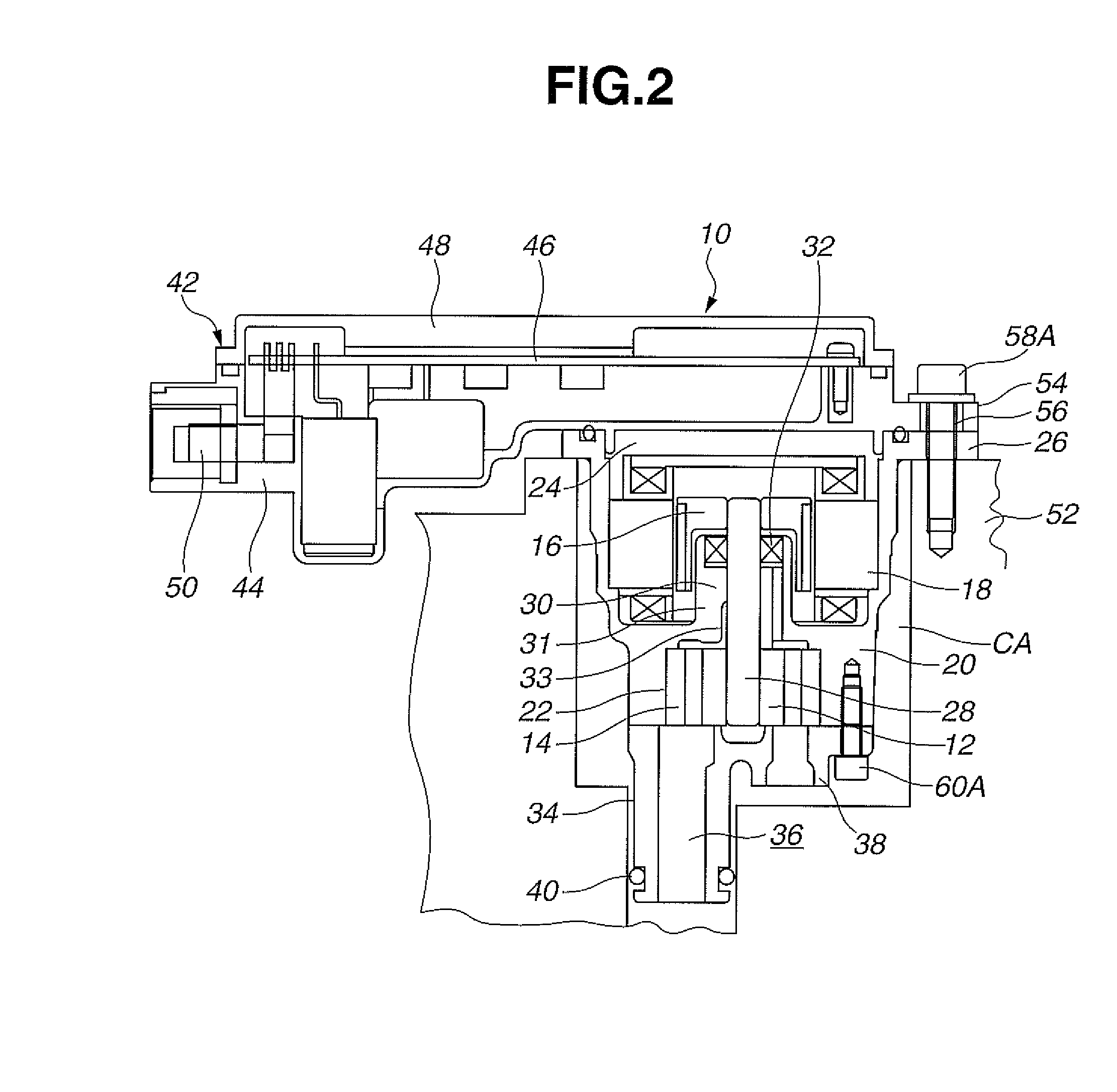

[0019]Referring now to the accompanying drawings, an embodiment of an electric oil pump according to the present invention will specifically be discussed; however, the invention is not limited to the illustrated embodiment, and modifications and variations of the illustrated embodiment will occur to those skilled in the art.

[0020]An electric oil pump is, for example, a pump to be mounded for automatic transmission of a vehicle having an idle stop function. The automatic transmission refers to a belt-type continuously variable transmission (hereinafter referred to as CVT) equipped separately with a mechanical pump driven by an engine. In the embodiment of the present invention, the electric oil pump is used as a hydraulic pressure supply source for automatic transmission and therefore fixed to a casing for automatic transmission.

[0021]At the time of stopping the engine under an idle stop control, the mechanical pump cannot ensure a hydraulic pressure. Additionally, if a hydraulic pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| driving current | aaaaa | aaaaa |

| corrosion resistance | aaaaa | aaaaa |

| heat resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com