Dual-textured snack with fiber blend

a fiber blend and snack technology, applied in baking, food shaping, baking products, etc., can solve the problems of reducing the moistness of the filling and the crispness of the outer shell, affecting the dual texture quality of the product, and difficult to achieve, so as to achieve the effect of high moisture conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

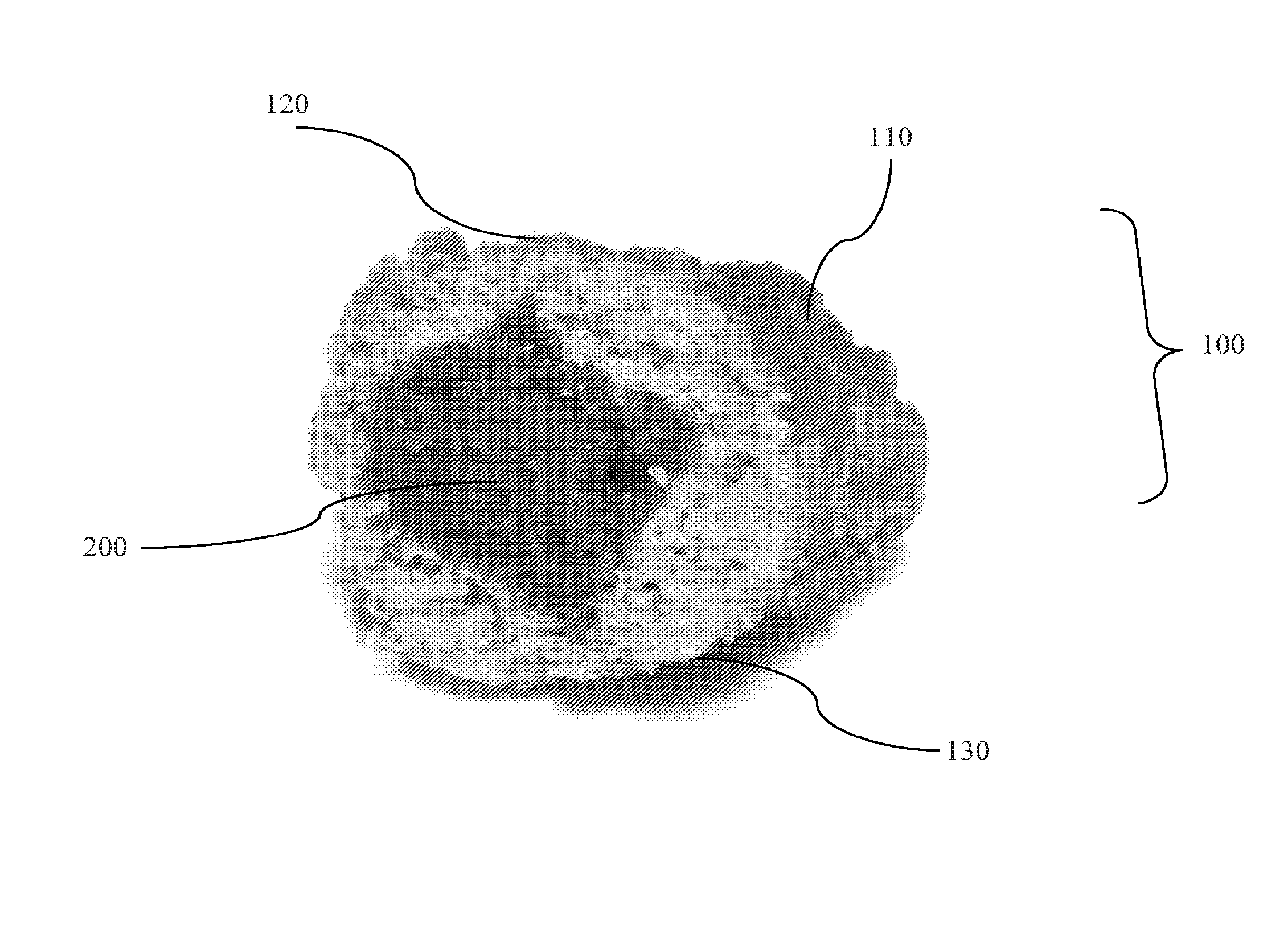

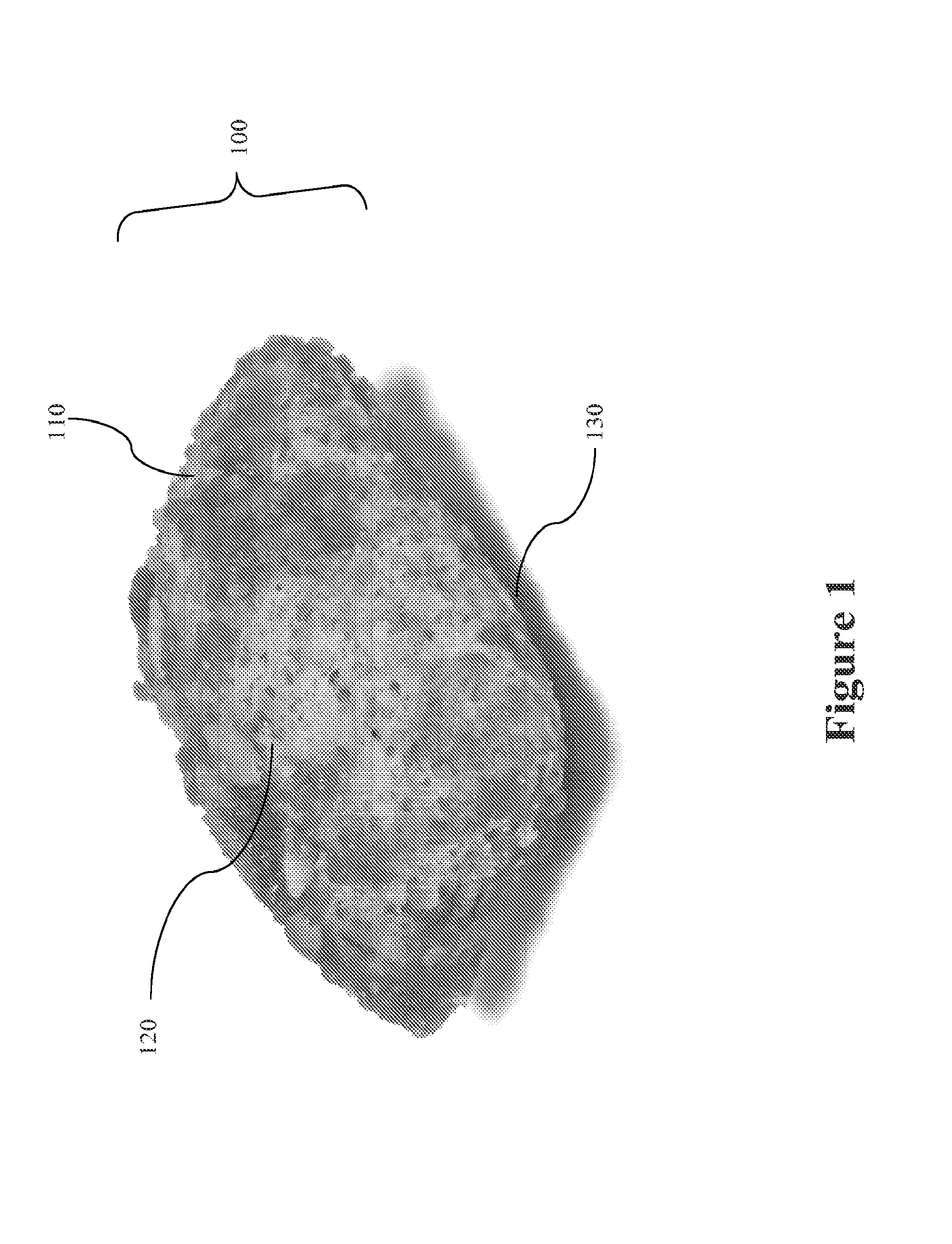

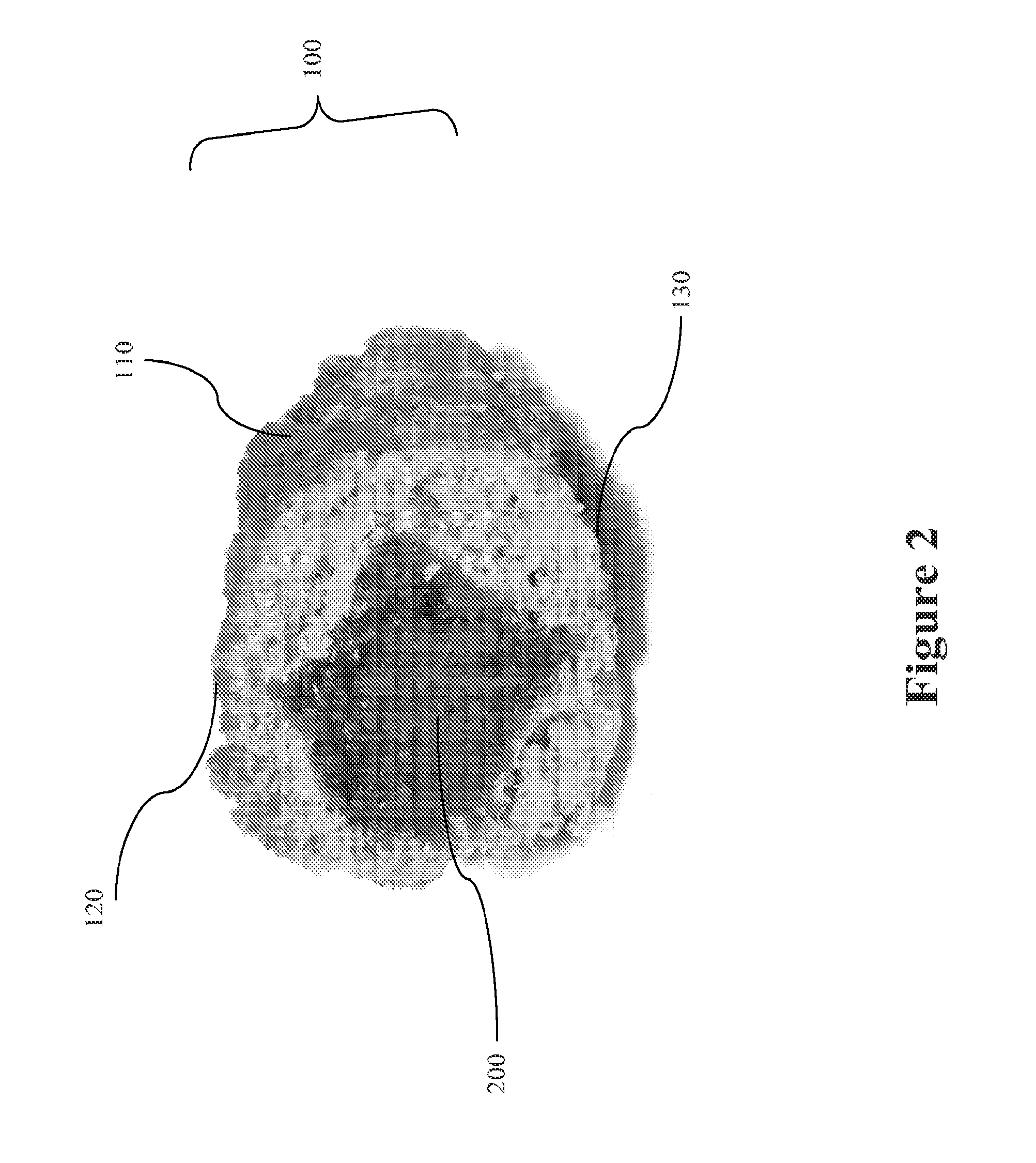

Image

Examples

example 1

[0066]A dough was prepared from the following formulation:

INGREDIENTSWt %Flour65% to 95%Granulated sugar 0% to 20%Dough salt0% to 2%Calcium carbonate0% to 2%Soluble corn fiber5% Resistant maltodextrin1% Oat fiber2% Water 5% to 50%100.00%

[0067]A filling was prepared according to the following formulation:

IngredientsWt (lb)Sugar (including syrups)200 to 700Fruit (powder, puree, fiber) 10 to 200Soluble corn fiber53.4Water15 to 100starch20 to 100Oat fiber23.4Texturizers, acidulants,10 to 50preservativesResistant maltodextrin12.1Natural / artificial color and 0 to 20flavorsSalt5.6

[0068]The dough and filling were coextruded in a ratio of 55% dough and 45% filling to product an unbaked foodstuff. The baked product displayed desirable dual texture (having a soft moist filling and a crispy dough-based casing) that resisted moisture migration.

example 2

[0069]Dough-based portions were prepared and tested with different fiber blends, according to the formulations below:

Ratio ofSoluble toInsolubleFormula 1% of FibersFiberSoluble corn fiber613Resistant maltodextrin14Oat fiber251

Formula 2RatioSoluble corn fiber909Oat fiber101

Formula 3RatioSoluble corn fiber300.43Oat fiber7011.00

[0070]The ratios listed in the table above represent the ratio of soluble fiber to insoluble fiber. Formula 1 included soluble fiber (soluble corn fiber and resistant maltodextrin) in a ratio of 3:1. Formula 2 included soluble fiber to insoluble fiber in a ratio of 9:1, and Formula 3 included soluble fiber to insoluble fiber in a ratio of 0.43:1.

[0071]Products for formulae 1, 2 and 3 described above were analyzed in a qualitative panel. The panel found that the texture of the foodstuffs prepared with the fiber blends of Formulae 1, 2, and 3 were each deemed acceptable, as they exhibited a dual texture having a crispy dough-based portion and a soft filling.

[0072]...

example 3

[0073]Foodstuffs were prepared with varying fiber blend levels in the filling and in the dough, and with varying amounts of filling in the foodstuff, as follows:

Filler FiberCasing FiberFiller LevelRun(%)(%)(%)13.6050203.23534435417505005062.52.5507603582.543590450100835116250121.8035

[0074]It was observed that the foodstuffs with less filling had crispier dough-based portions and less taste from the filling, while the foodstuffs with more filling had less crispy dough-based portions and fuller flavor from the filling. Additionally, the foodstuffs including fiber in both the filling and the dough-based portion demonstrated a crispier texture, which remained crispier over time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com