Integrated fluidic flow network for fluid management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 700

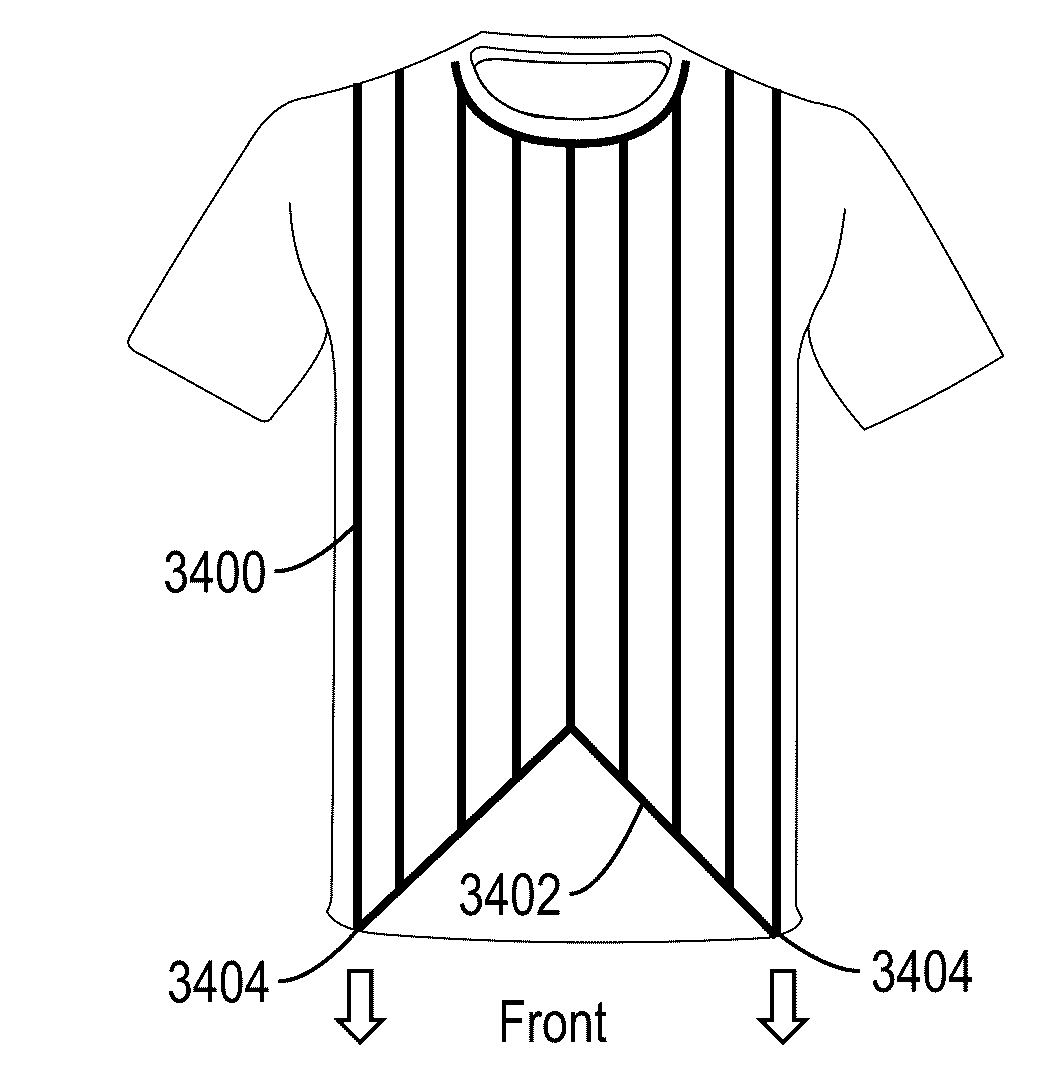

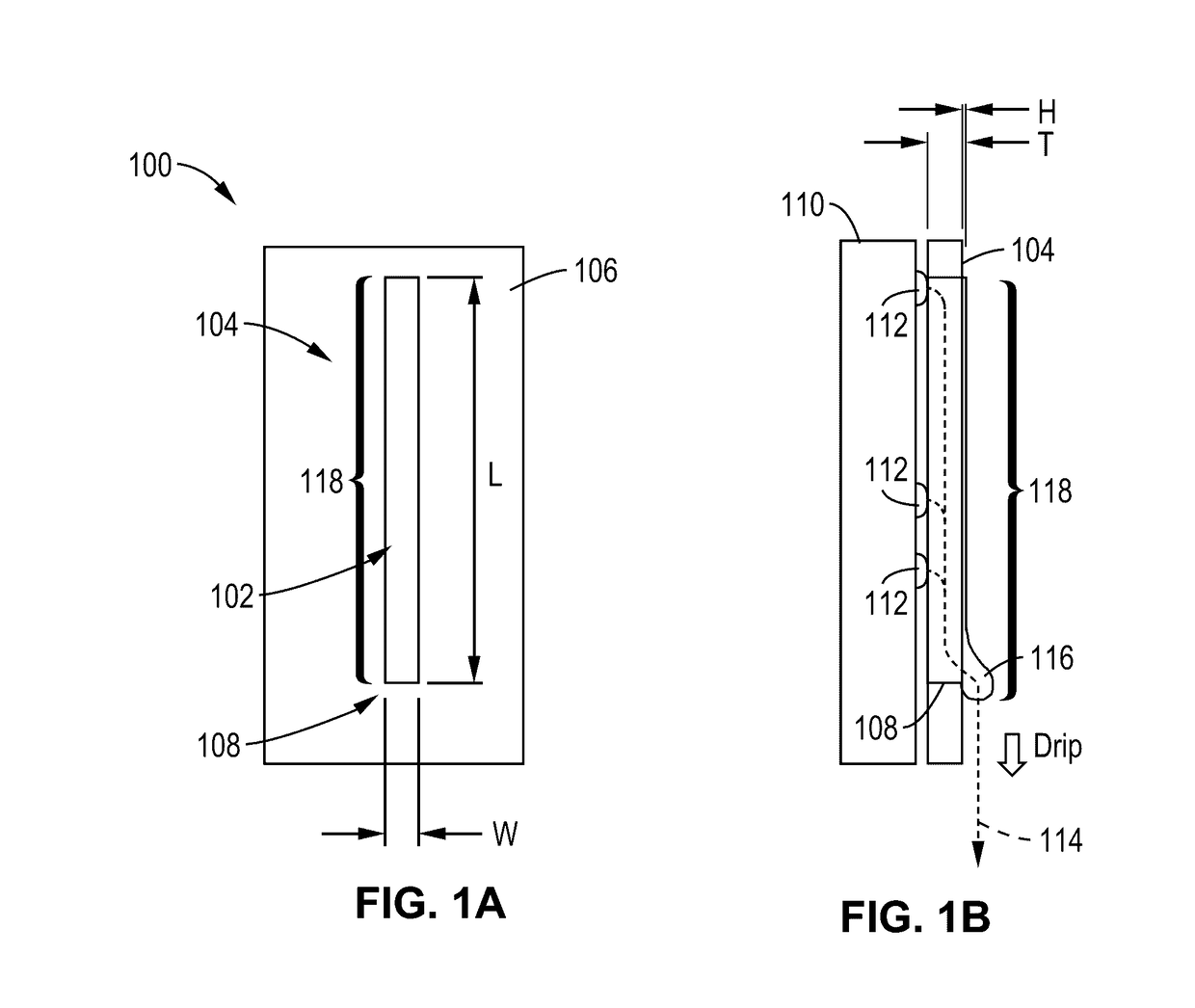

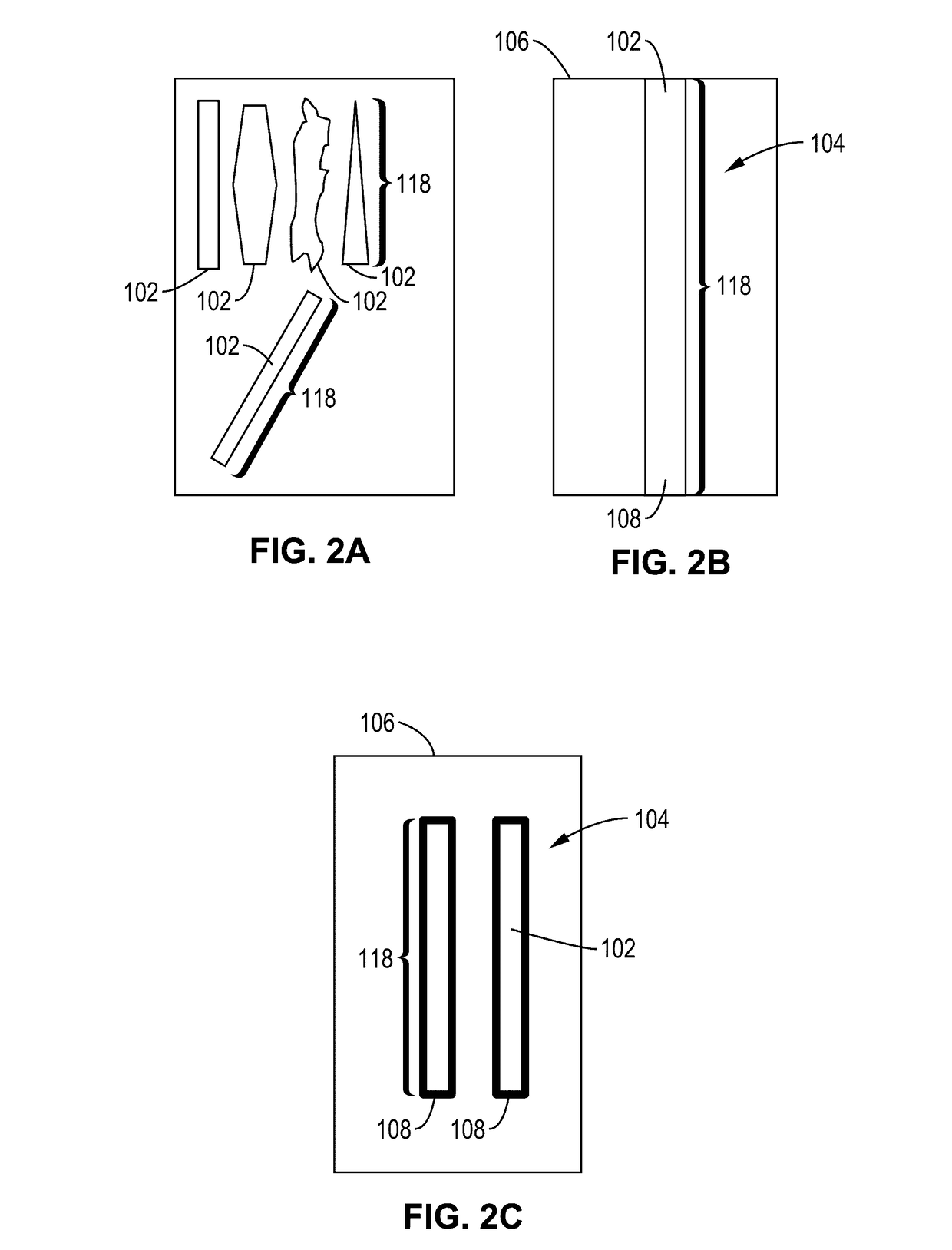

[0123]FIG. 7A through FIG. 7C are diagrams that illustrate an embodiment 700 in which the inner surface layer of the material 106, shown in FIG. 7A, has more liquid-repellent region 104 area coverage than the outer surface layer of the material, shown in FIG. 7C. The inner surface layer (in contact with the liquid-producing surface) of the material has a discontinuous liquid-absorptive region 102 in a pattern 702 made up of small circles (or any other shape). These liquid-absorptive regions 102 on the inner surface of the material are connected through liquid-absorptive paths 704 to the outer layer liquid-absorptive channels 118 of the material, as shown in the cross-section view in FIG. 7B. The liquid-absorptive regions 102 forming the pattern 702 on the inner surface layer of the material serve as small inlets that suck moisture to the outer siphon networks (liquid-absorptive channels 118). The moisture removal rate of this structure from an inner surface layer to an outer layer i...

embodiment 800

[0125]In the embodiment 800 shown in FIG. 8A through FIG. 8C, the inner layer of the material, shown in FIG. 8A, has 5 mm liquid-absorptive circles 802 with a 5 mm space between each circle 802. The uniformly distributed liquid-absorptive pattern ensures an efficient capture of moisture. The liquid-absorptive circles penetrate through the material substrate and connect to the outer layer of the material which has a fluidic channel network design that connects the entire liquid-absorptive circle pattern on the inner layer of the material. The channel design uses a minimum number of channels 118 to connect all of the liquid-absorptive circles so that the overall wet area on the material is minimized. The outside layer channel patterns are also designed so that they can be repeated over the entire material substrate. FIG. 8B shows a cross-sectional view of the design. FIG. 8C shows the outer surface of the material. The outer layer channels 118 are mainly vertical (5.5 mm in width and ...

embodiment 1100

[0129]Similarly, the diagrams in FIG. 11A through FIG. 11C show an embodiment 1100 in which the outer surface layer (FIG. 11C) of the fluidic channel network pattern is completely covered by a liquid-repellent coating, as shown in the cross-sectional view in FIG. 11B. The inner surface layer of the pattern can remain constant from the top of the material to the dripping point 108 as shown here or can resemble any of the embodiments previously shown or any other patterns suited for a particular need. This provides a region where moisture can contact the channel 118 and flow inside the material but is not visible from the outside of the material, as shown in FIG. 11C. This embodiment can be particularly useful when made into a compression garment, which will generate contact pressure that pushes the moisture towards the liquid-absorptive region 102 patterns. The accumulated moisture can be kept or transported away by the liquid-absorptive channel 118 structure. Furthermore, this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com