Protective film detecting method for laser processing

a technology of laser processing and protective film, which is applied in the direction of fluorescence/phosphorescence, instruments, semiconductor/solid-state device testing/measurement, etc., can solve the problems of reducing laser processing productivity, laser processing may be hindered by the protective film, and the wafer cannot be sufficiently protected, so as to accurately measure the thickness of the protective film and reduce laser processing productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

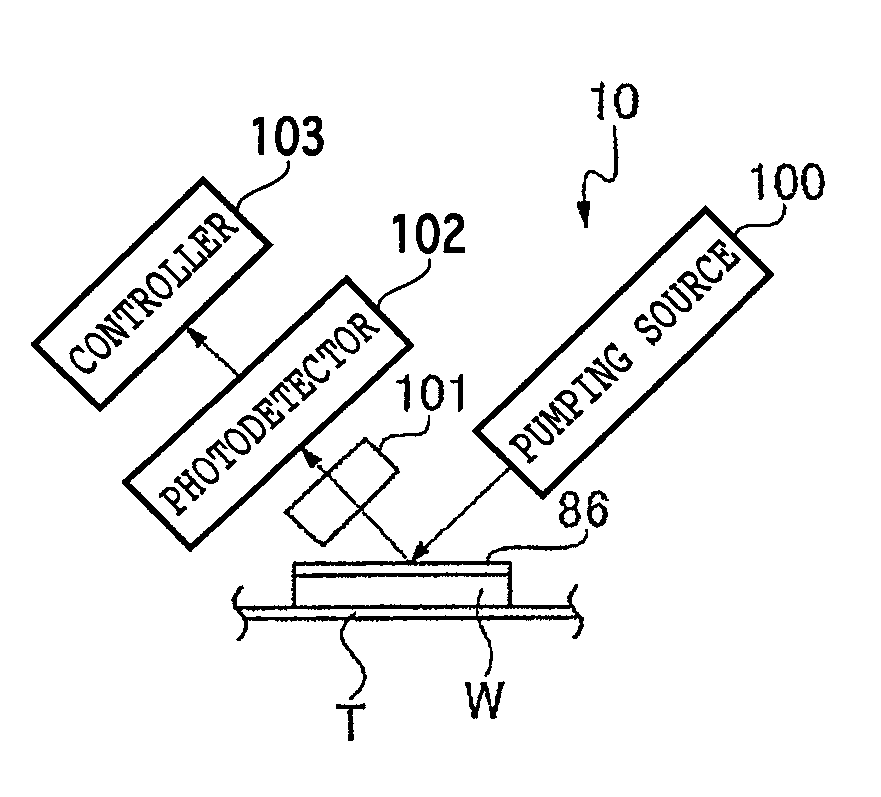

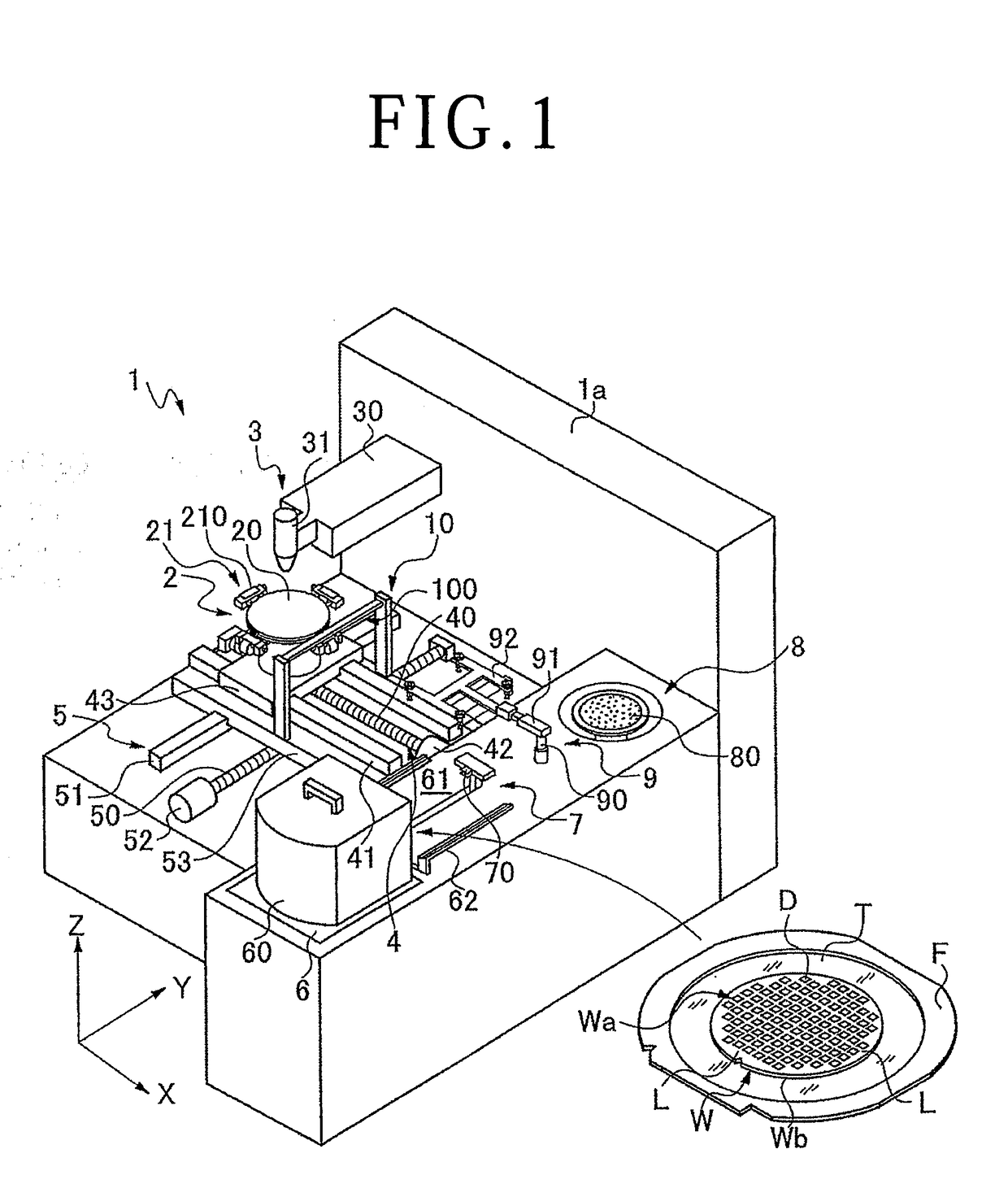

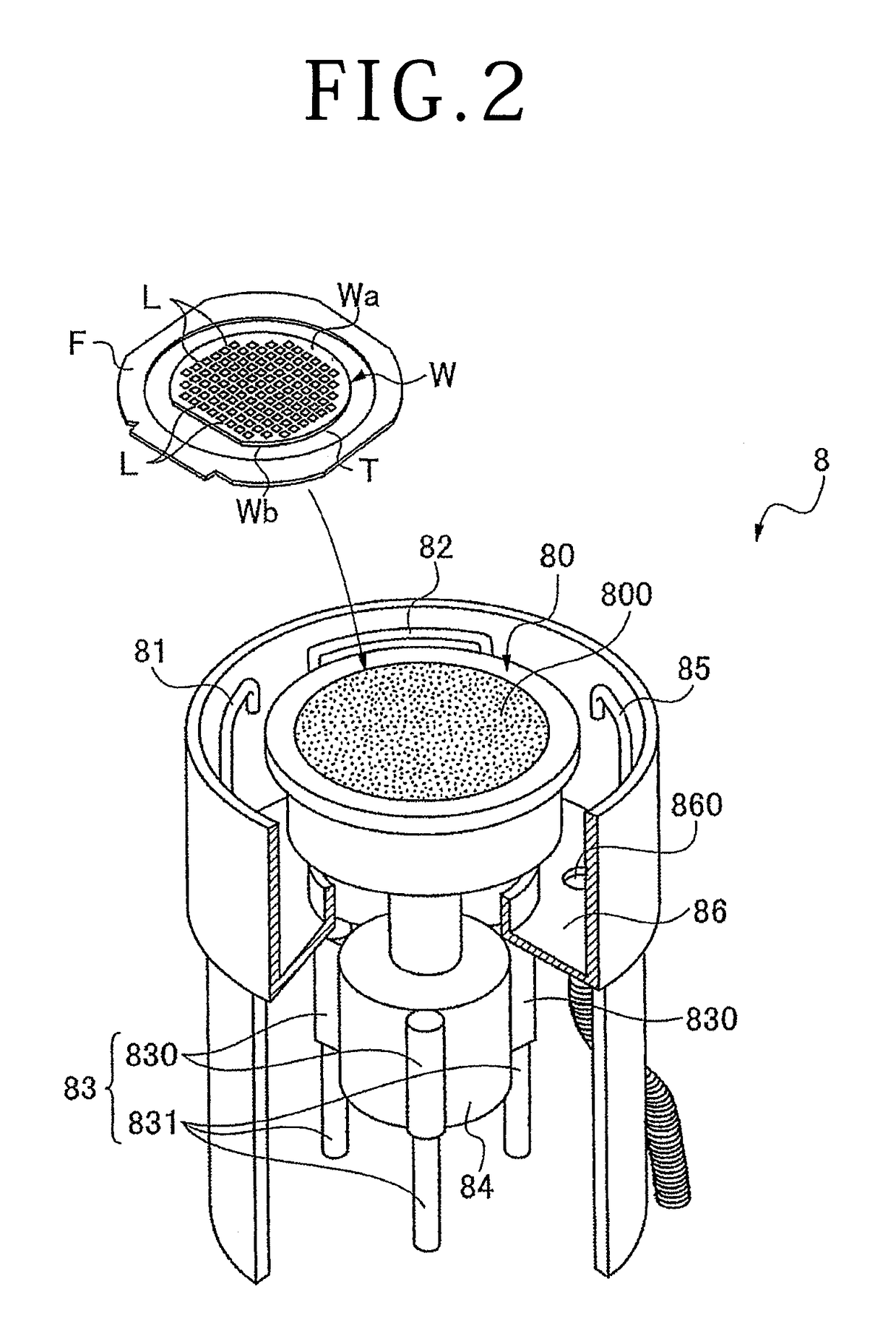

[0036]Referring to FIG. 1, there is shown a laser processing apparatus 1 for use in performing the present invention. The laser processing apparatus 1 shown in FIG. 1 has a function of forming a protective film on the front side Wa of a workpiece W, a function of determining whether or not the protective film formed has a desired thickness, and a function of laser-processing the workpiece W. The laser processing apparatus 1 includes a cassette mounting area 6 for mounting a cassette 60 storing the workpiece W as a target to be laser-processed, workpiece handling means 7 for handling the workpiece W to take it out of the cassette 60 before laser processing or store it into the cassette 60 after laser processing, protective film forming means 8 for forming a protective film on the front side Wa of the workpiece W taken out of the cassette 60, a chuck table 2 for holding the workpiece W on which the protective film has been formed, and laser beam applying means 3 for applying a laser b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| peak wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com