Floor drain

a floor drain and drain pipe technology, applied in the field of floor drains, can solve the problems of inability to inspect the connection between the feed of the heat exchanger tube the conduit for cold mains water, significant amount of unused energy loss, and undesirable discharge of hot waste water without recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

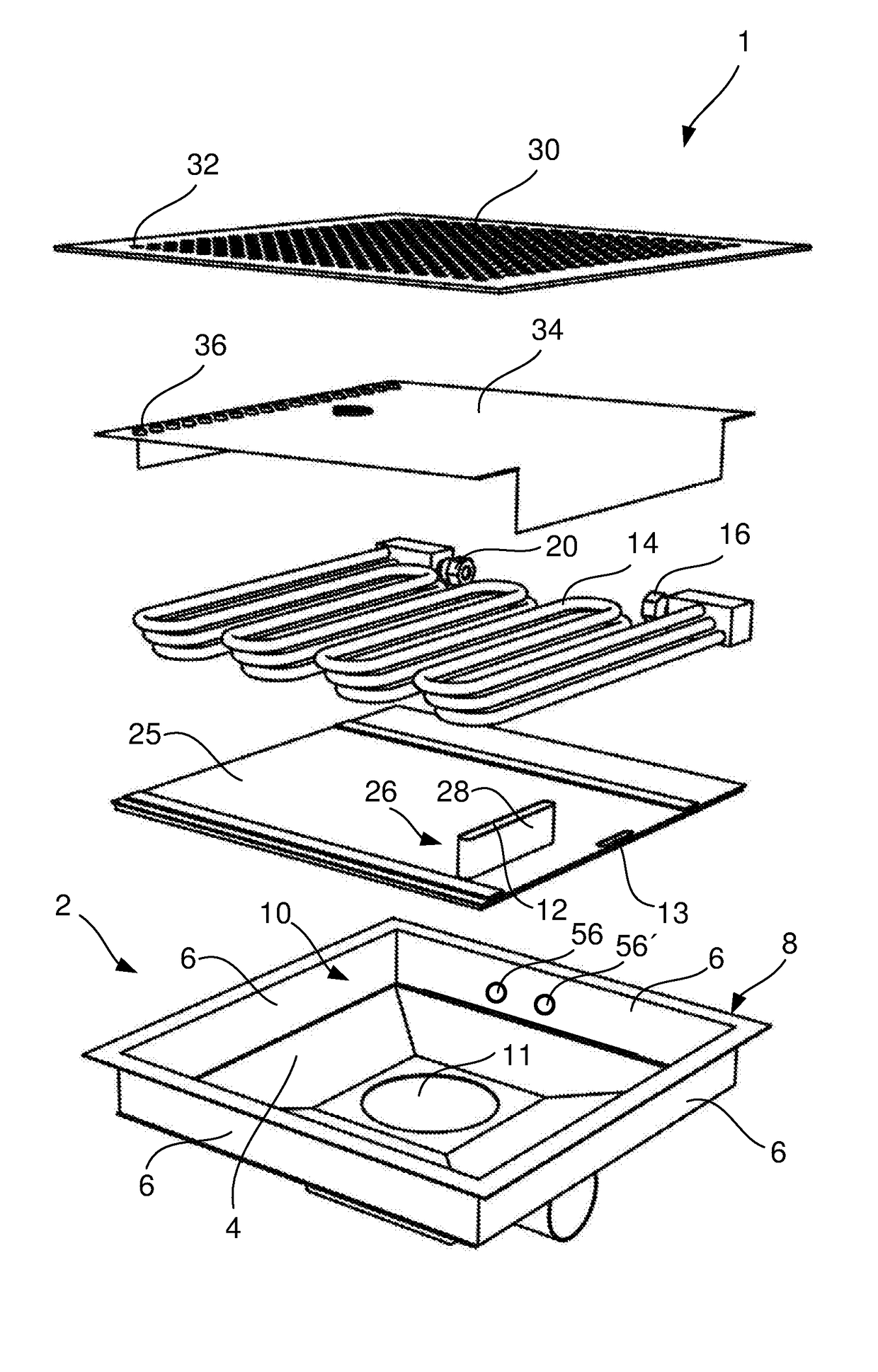

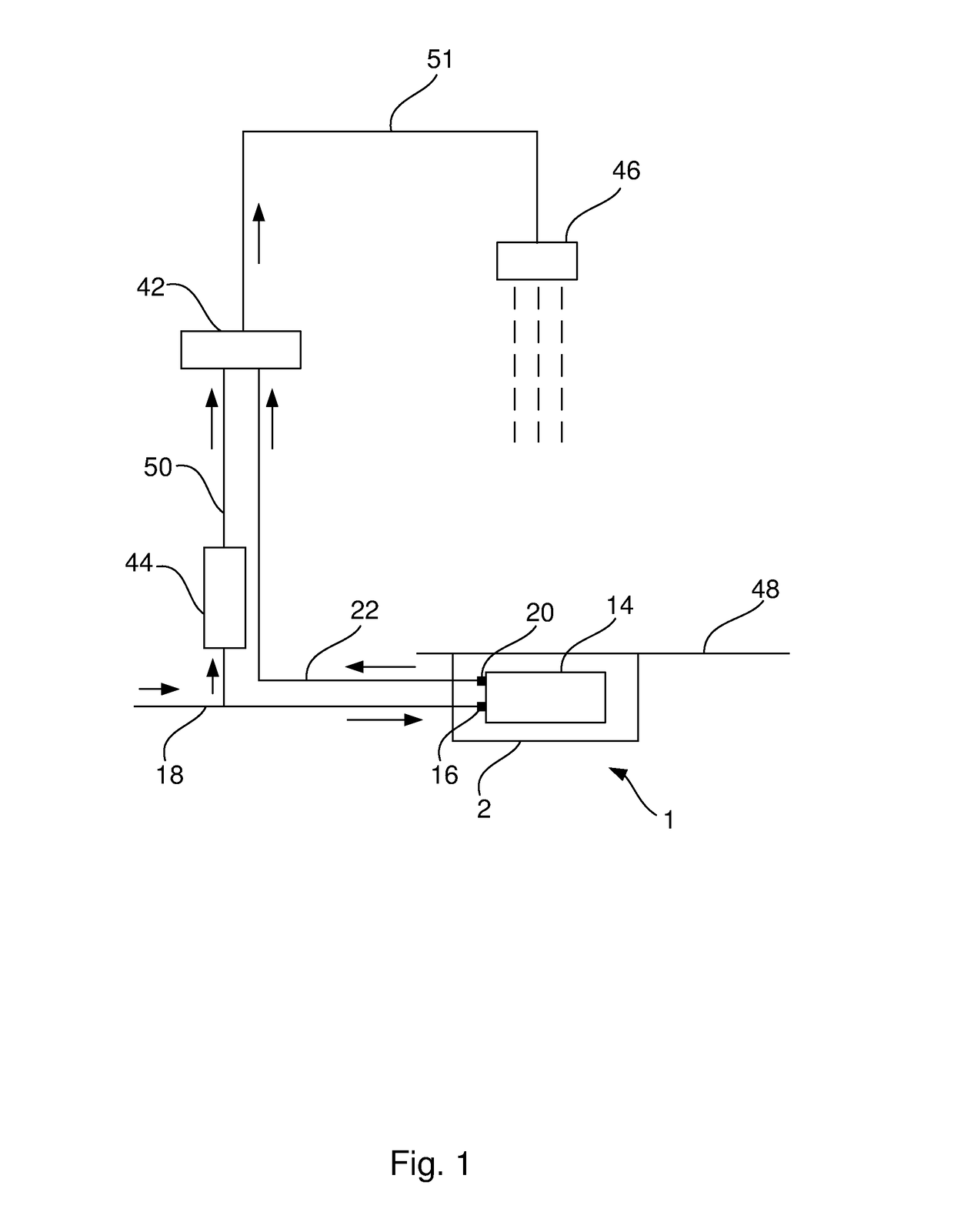

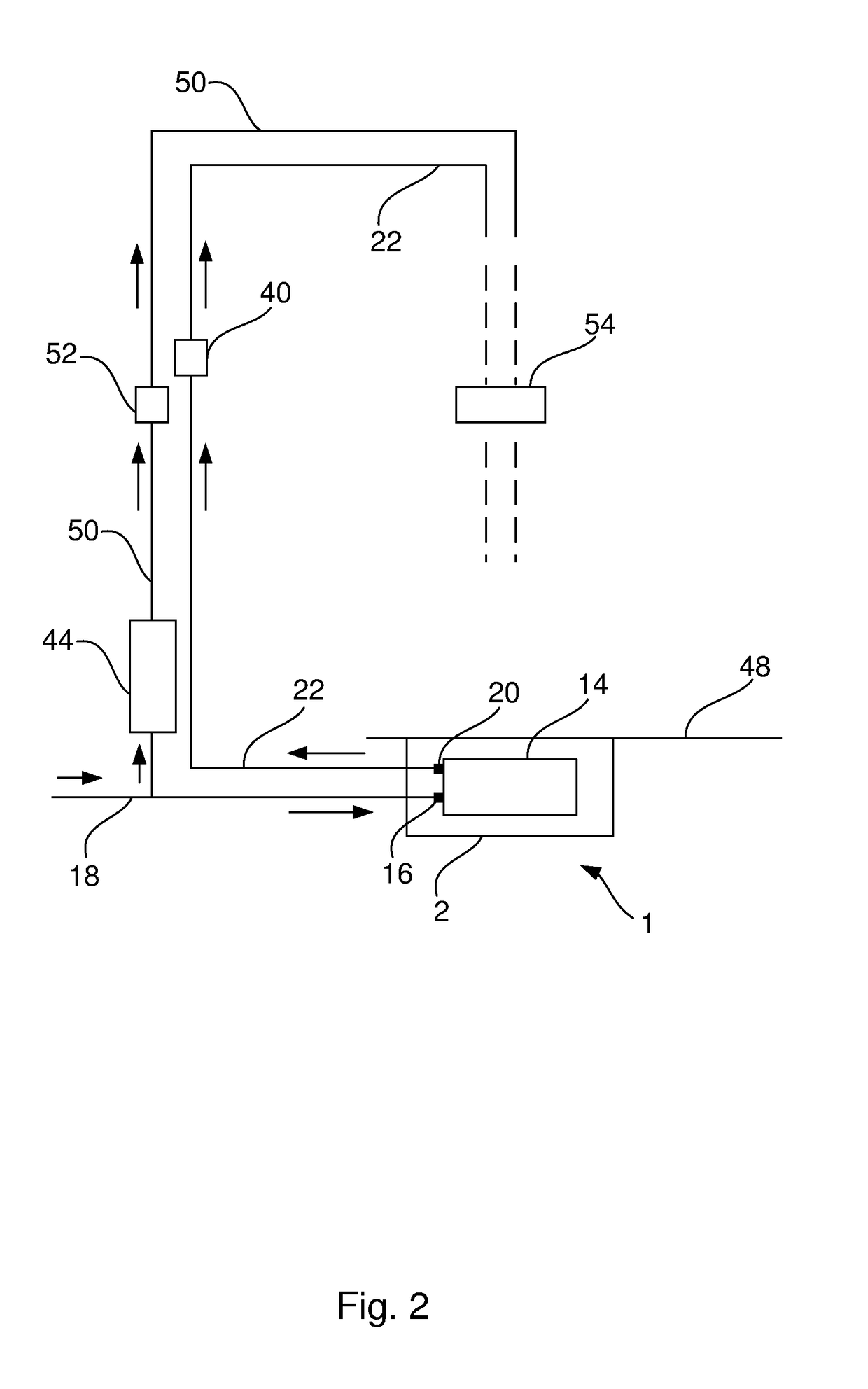

[0035]FIG. 1-4 show schematic views illustrating the effect obtained by using the floor drain 1 according to the present invention. In FIG. 1-4, the dashed lines are water and the straight arrows show the direction of the water flow. A shower is shown in FIG. 1-4. It is also possible to use the floor drain 1 together with a bath tub, a washing machine, a dish washer or any other appliance where hot and cold water are to be mixed just before use. The effect will first be described with reference to FIG. 1.

[0036]A shower head 46 is arranged above the floor drain 1 which is arranged in a floor 48. The definition of a “floor drain” is a drain that is installed in a floor so that the top of the floor drain is substantially in the same level as the floor surface. The floor drain 1 comprises a heat exchanger element 14 arranged inside a drain compartment 2. The heat exchanger element 14 is connected with a first connection 16 to a first conduit 18 for fresh water having a first temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com