Cigar shaped smoking device with reverse calabash chamber

a smoking device and cigar-shaped technology, applied in the direction of tobacco pipes, applications, tobacco, etc., can solve the problems of large and relatively defect-free briar, difficult to find, and limited quantity of briar, so as to reduce the cost of manufacturing, reduce the cost of material costs, and reduce the difficulty of manufacturing. design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

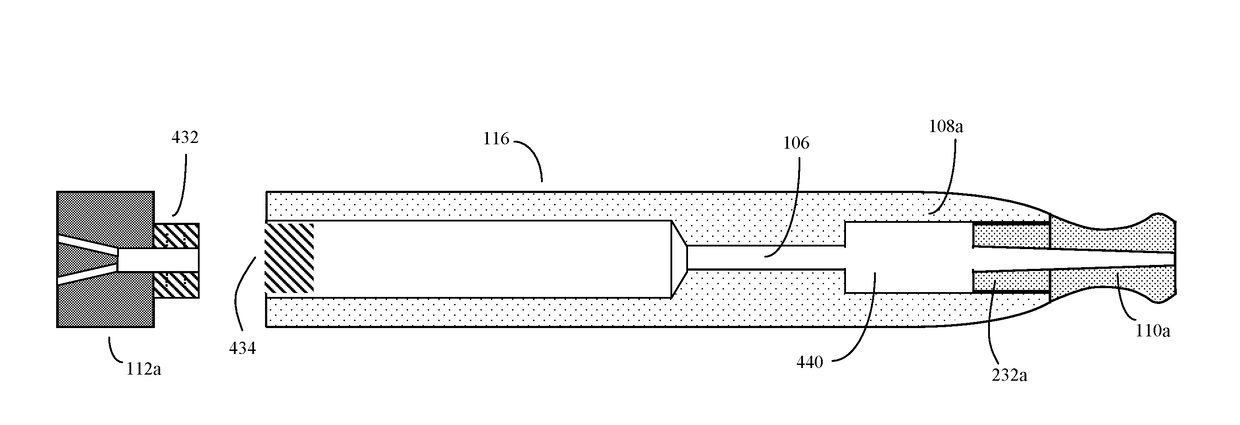

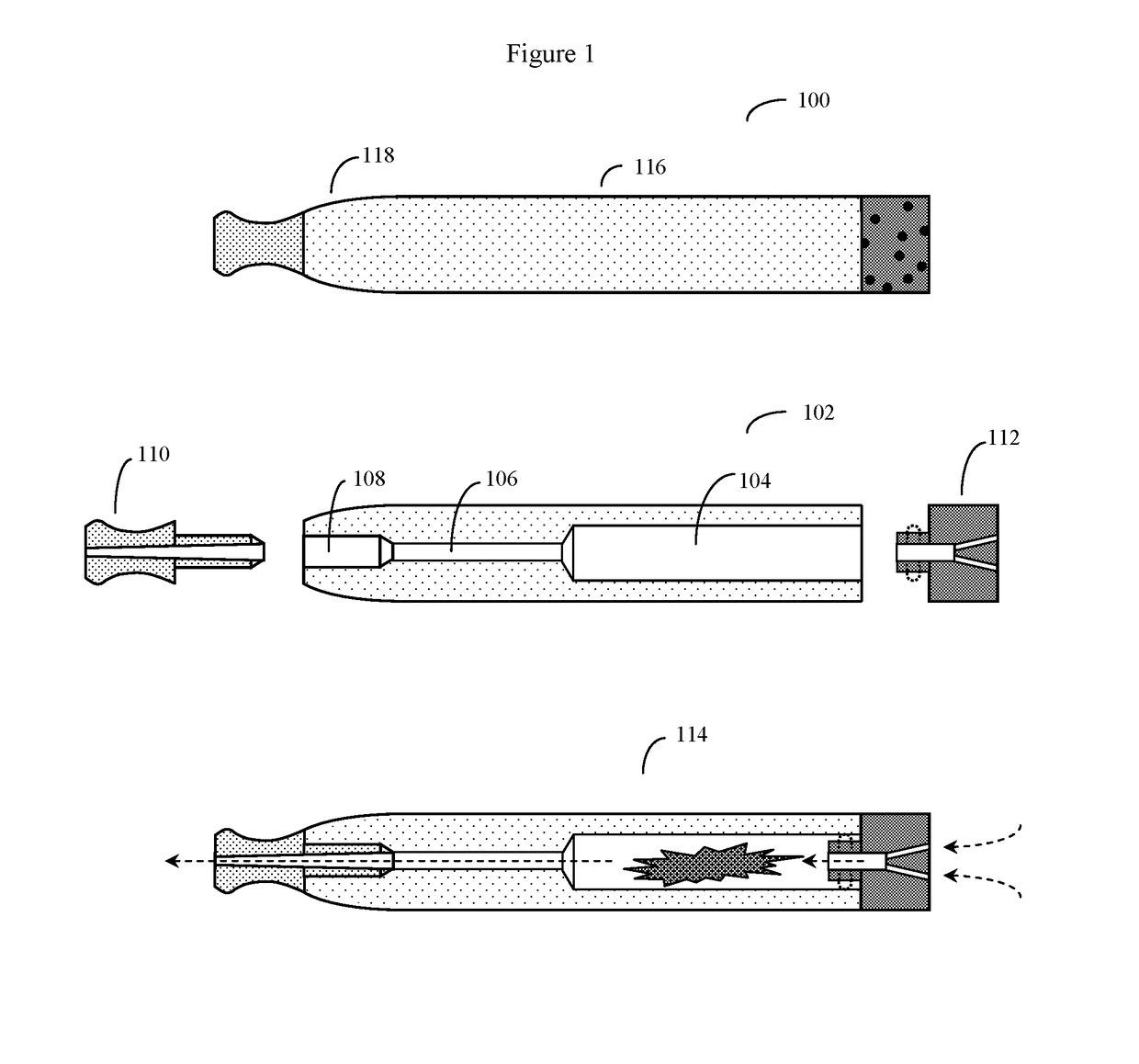

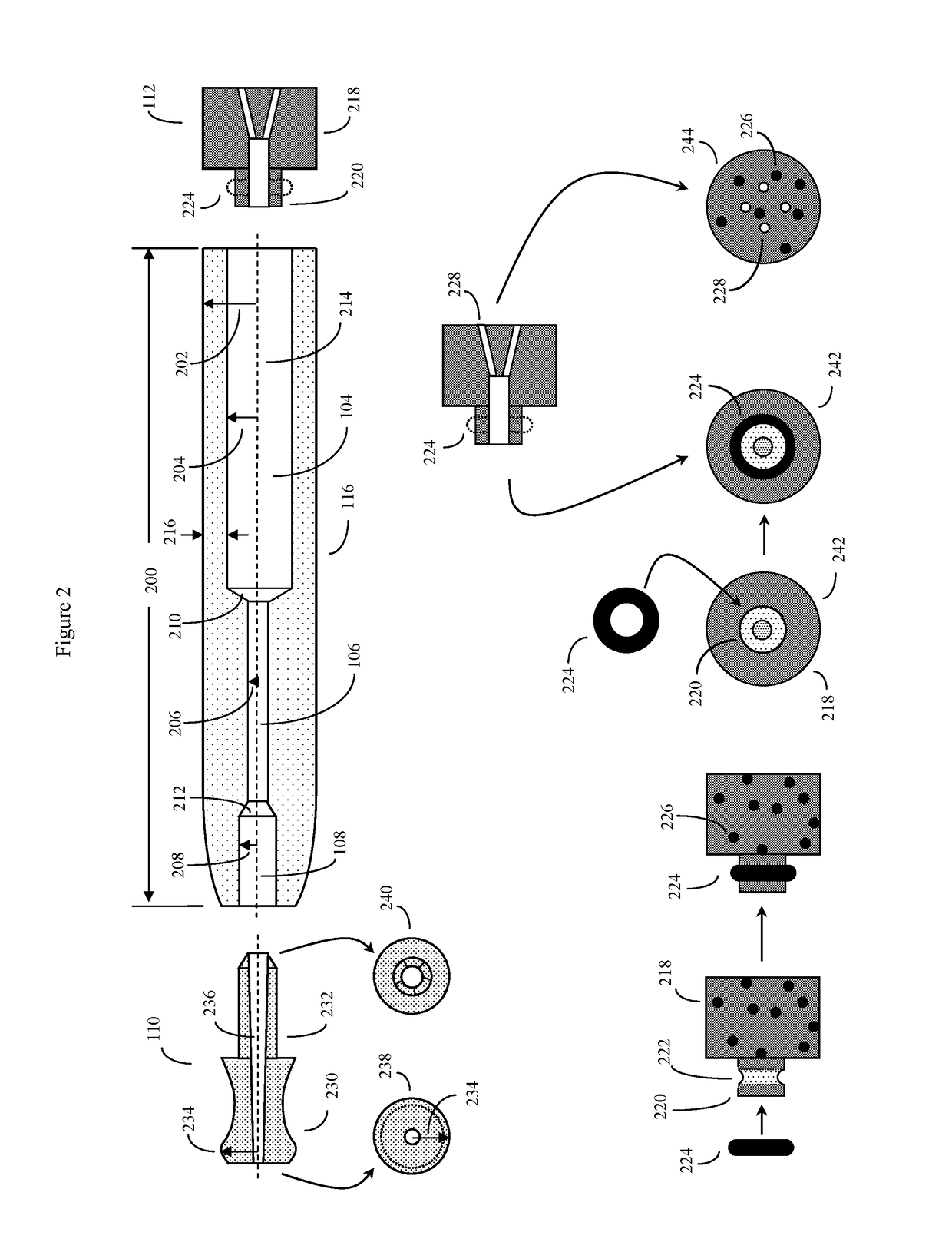

[0028]In one embodiment, the invention may be a substantially cylindrical smoking pipe, and will often be referred to in this specification in the alternative as a cigar shaped smoking device, device, or pipe. FIG. 1 shows the exterior of an assembled cigar shaped smoking device (100), an exploded cross section (102) showing the internal chambers (104), (106), (108), mouthpiece (110), and optional end cap of the device (112), and the combustion process and air flow that occurs when the device is in use (114).

[0029]This pipe will generally comprise a substantially a substantially cylindrical body (116). That is, although the body of the device may deviate somewhat from a true cylinder—it may be textured, and may also have a curved end (118), particularly near the mouthpiece. Thus from a distance, the overall impression of the body of the device, and indeed the device as a whole, will be that it is a roughly cylindrical object.

[0030]In a preferred embodiment, the body (116) may be mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com