Peristaltic pump device

a pump device and peristaltic technology, applied in the direction of pump components, positive displacement liquid engines, pump control, etc., can solve the problems of rapid decrease in flow rate, difficult to sufficiently reduce pulsation, and inability to rotate the pump, so as to reduce the pulsation of the discharge flow rate, increase the rotation speed, and reduce the effect of discharge flow ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

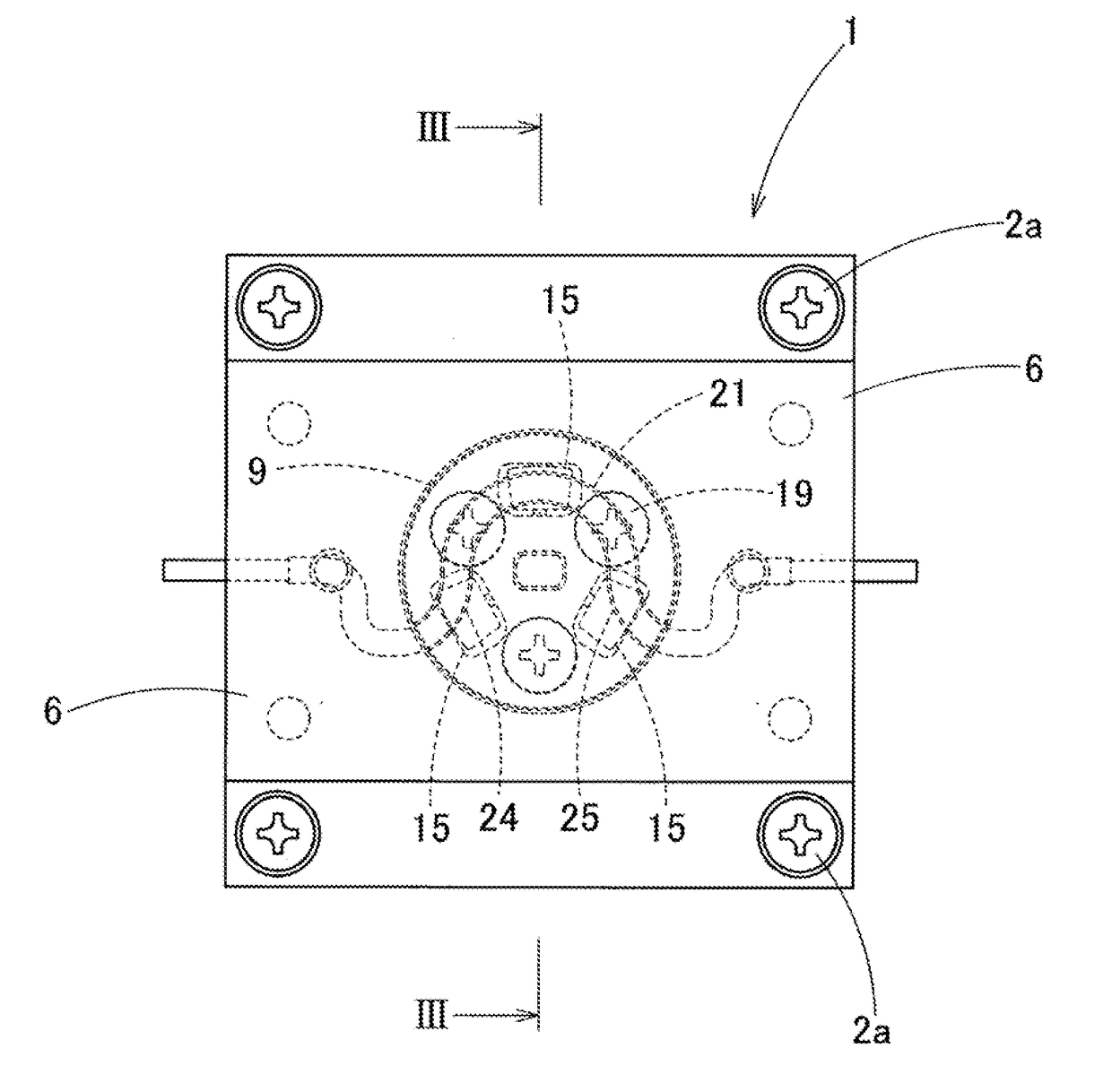

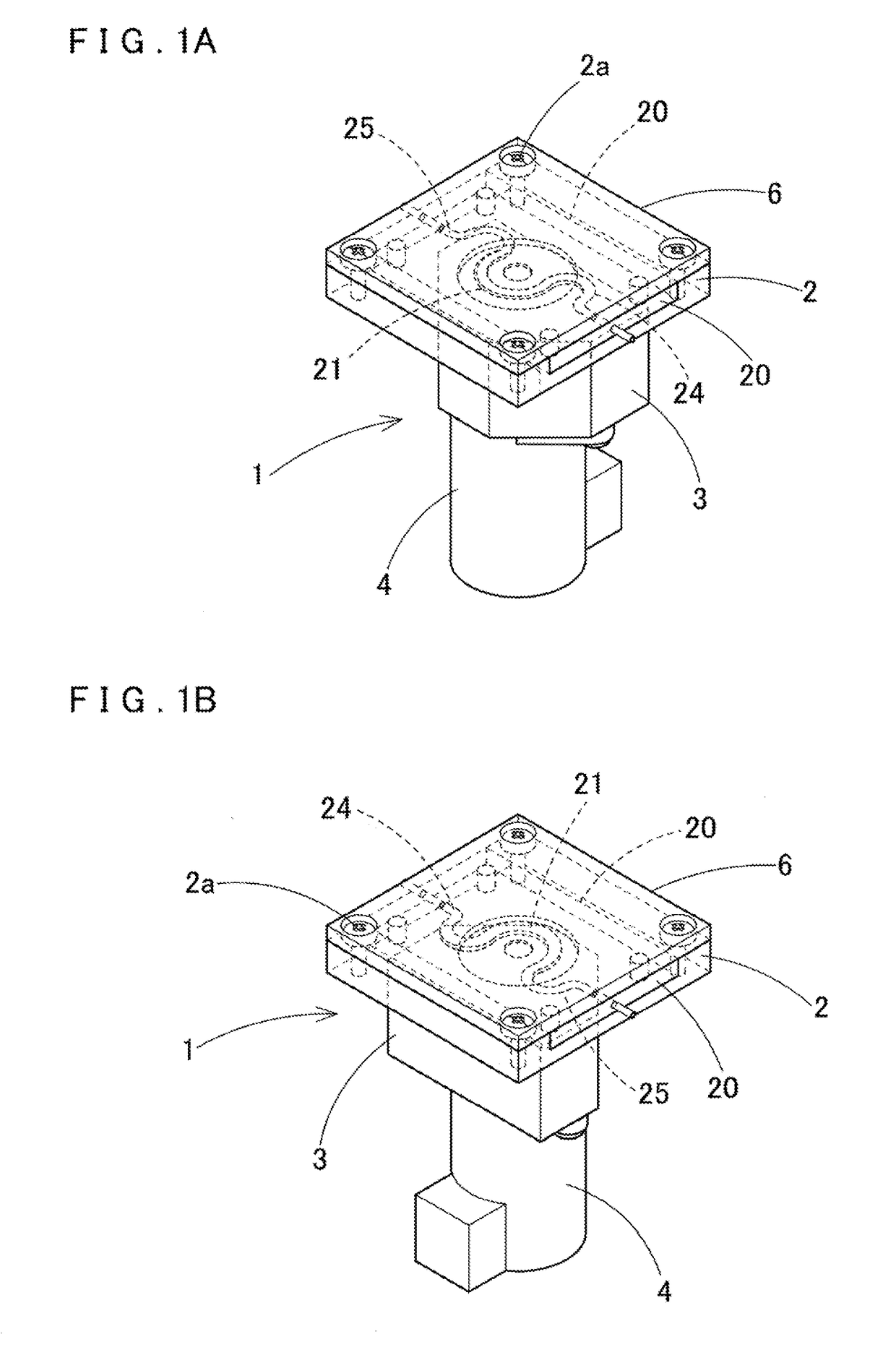

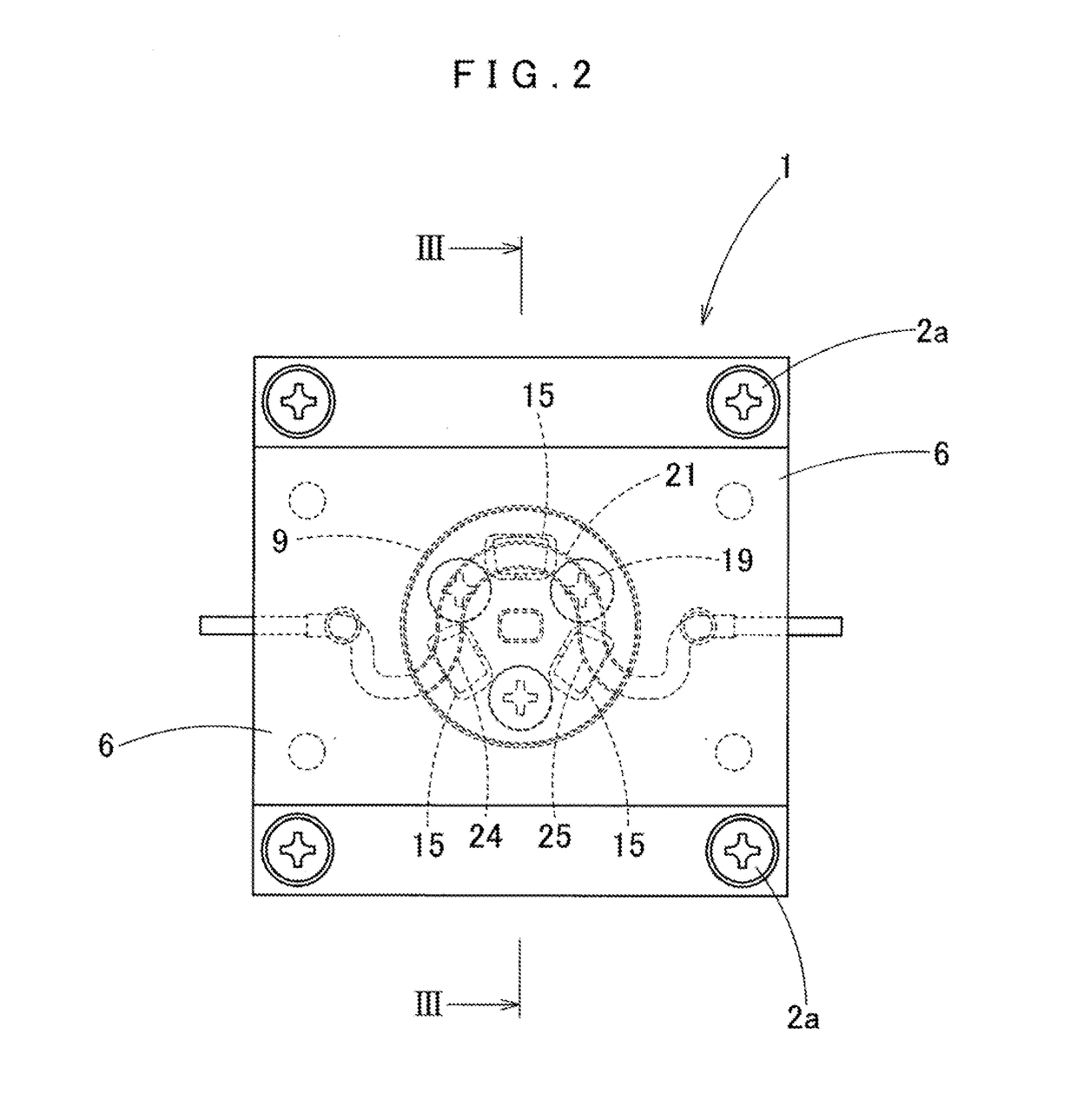

[0047]FIG. 1 to FIG. 17 show a peristaltic pump device and this peristaltic pump device includes, as shown in FIG. 15, a base 2 that houses a microfluidic chip 20, a micro peristaltic pump 1 that is fixed to a lower portion of the base 2 and drives a rotor 10 by a motor 4, and a control circuit 30 that controls a rotation speed of the motor 4.

[0048]To an upper portion of the micro peristaltic pump 1, the rotor 10 to be driven by the motor 4 is attached, and on a horizontal surface of the rotor 10, three rollers 15 are pivotally supported radially at intervals, and the three rollers 15 are pressed against a circular arc shaped flow path 21 formed inside a concave portion 27 of the microfluidic chip 20, and the rotor 10 and the rollers 15 are rotated to send a liquid at a micro flow rate.

[0049]In the micro peristaltic pump 1, schematically, a circular arc shaped flow path 21 is formed as a microfluidic flow path inside a sheet-like microfluidic chip 20, three rollers 15 of the rotor ...

second embodiment

[0089]FIG. 20 to FIG. 23 show a peristaltic pump device of a second embodiment, and FIG. 20 shows a microfluidic chip 220 of the same. In the plan views shown in FIG. 20, FIG. 21, and FIG. 23, the lines showing internal flow paths, etc., which do not appear in the plan view of the microfluidic chip 220 are shown by solid lines for easy understanding.

[0090]The microfluidic chip 220 is formed to be rectangular sheet-like from a polymeric elastic body which is soft transparent synthetic resin such as PDMS or silicone resin. A circular concave portion 227 is formed in the center of the main body of the microfluidic chip 220, and a circular arc shaped flow path 221 is formed in the concave portion 227. A radius of the circular are shaped flow path 221 is the same as the radius of the rotational trajectory 5 of the three rollers 15 (FIG. 7) on the rotor 10 (FIG. 7), and the rollers accurately roll on and press a lower surface of the circular arc shaped flow path 221. A width in the transv...

third embodiment

[0115]FIG. 24 to FIG. 26 show a microfluidic chip 320 of the peristaltic pump device. In FIG. 24 to FIG. 26, for convenience of description, a state where the inner surface of the microfluidic chip 320 is turned upward is shown, and the microfluidic chip 320 shown in the drawings is housed inside the chip housing portion 8 on the base 2 in a state turned inside out from the form shown in the drawings, to be used.

[0116]This microfluidic chip 320 is manufactured in the same manner as described above, for example, by using two polymeric elastic sheets (sheet such as a PDMS) having the same thickness, the lower sheet is superposed onto the upper sheet, and the lower sheet is molded to form a circular concave portion 327 at the center, and a circular arc shaped flow path 321 is further formed in the concave portion 327.

[0117]At that time, the circular arc shaped flow path 321 in the concave portion 327 is manufactured by bonding so as to cause a part of the lower thinner second elastic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com