Proton exchange membrane electrolyzer

a technology of proton exchange membrane and electrolyzer, which is applied in the direction of electrolysis process, electrolysis components, diaphragms, etc., can solve the problems of high cost of electrolyzer production, so as to achieve economic and affordable daily application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

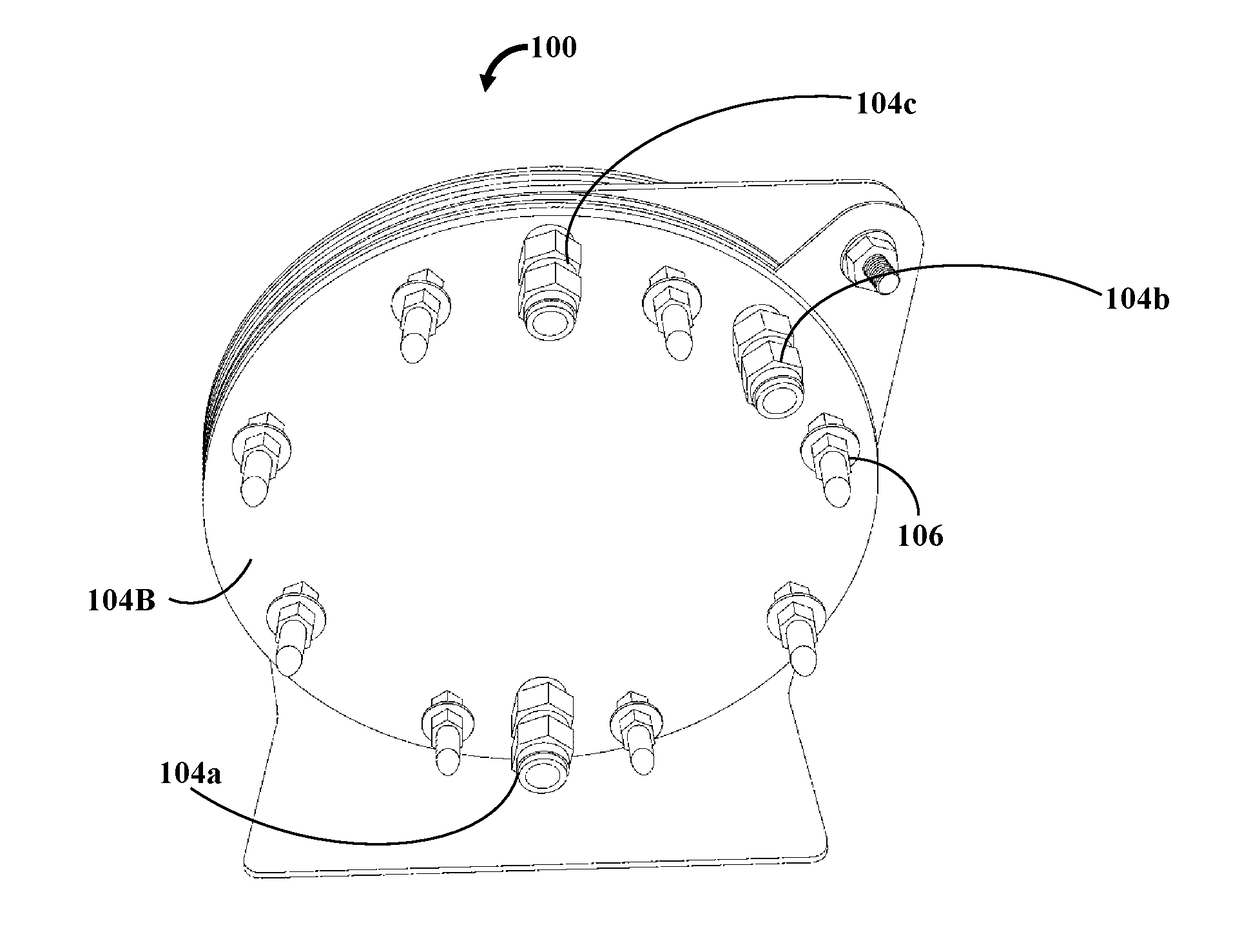

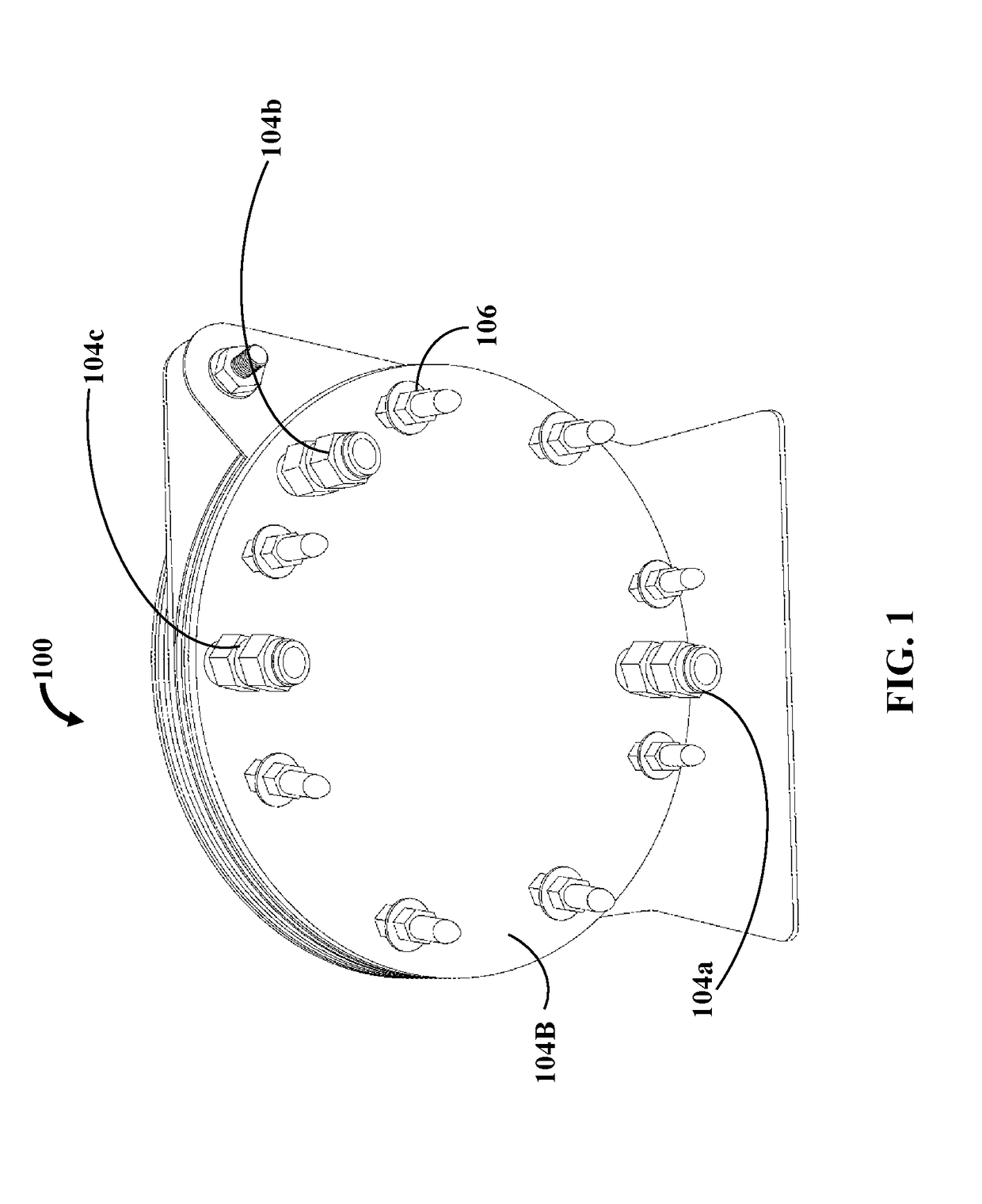

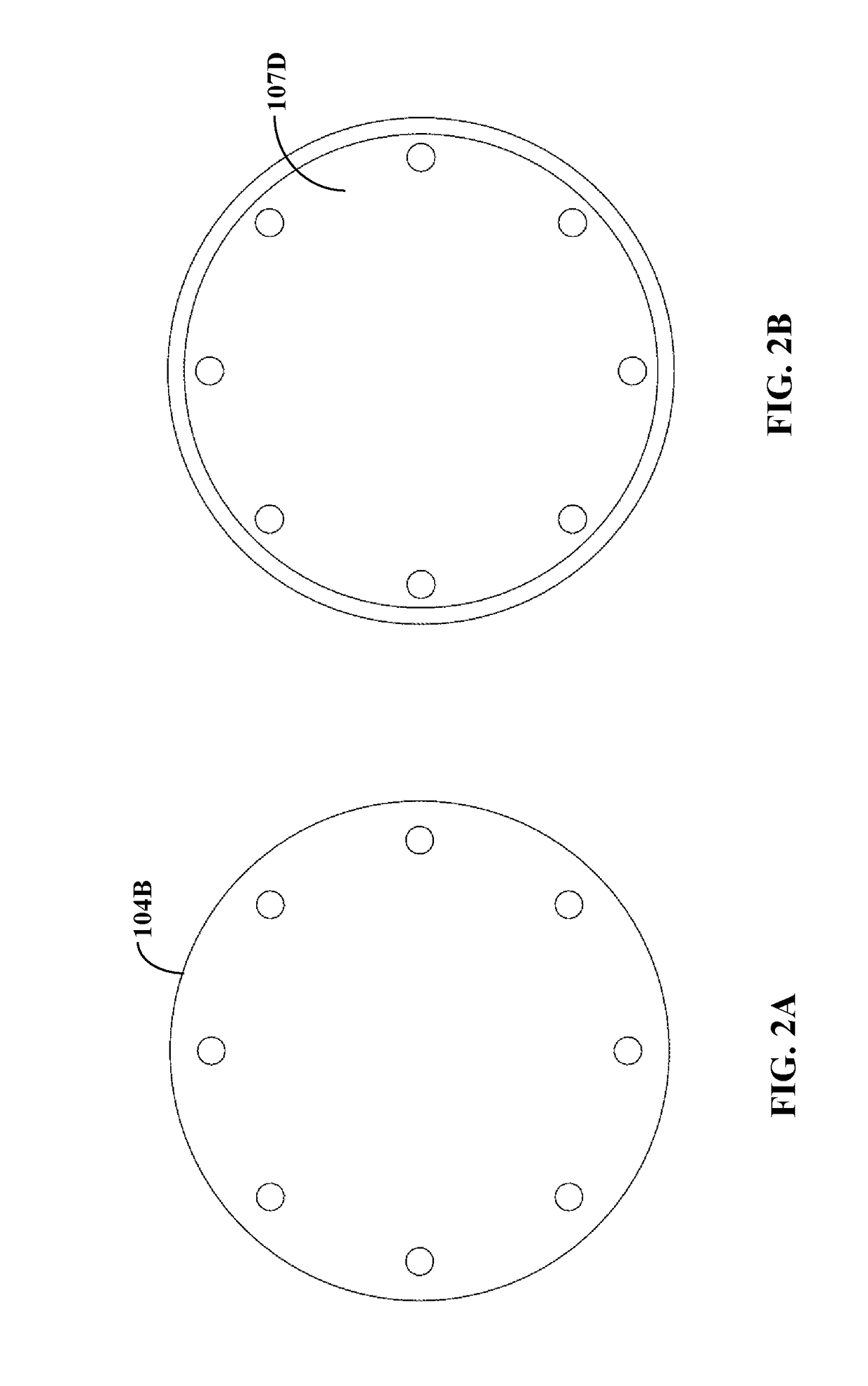

[0039]FIG. 1 exemplarily illustrates a perspective view of a proton exchange membrane (PEM) electrolyzer 100. In an embodiment, the PEM electrolyzer 100 is constructed with one stack (one cell) or multiple stacks depending on the amount of hydrogen and oxygen required for a specific application. In an embodiment, the proton exchange membrane (PEM) electrolyzer 100 is a device for breaking down water to hydrogen and oxygen. In one embodiment, the PEM electrolyzer 100 comprises a titanium anode 101, two catalyst-coated membrane (membrane electrode assembly) 102, a titanium cathode 103, a titanium neutral plate 109, and a power source. The titanium anode 101 is exemplarily illustrated in FIG. 2C. The catalyst-coated membrane 102 is exemplarily illustrated in FIGS. 2I and 2U. The titanium cathode 103 is exemplarily illustrated in FIGS. 2AA-2BB. The titanium neutral plate 109 is exemplarily illustrated in FIGS. 2O and 2P. In one embodiment, the PEM electrolyzer 100 comprises a titanium a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage rating | aaaaa | aaaaa |

| current rating | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com