Exhaust system for vehicle

a technology for exhaust systems and vehicles, applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems of serious affecting combustion and horse power, and the intake cannot be smooth, and achieve the effect of solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

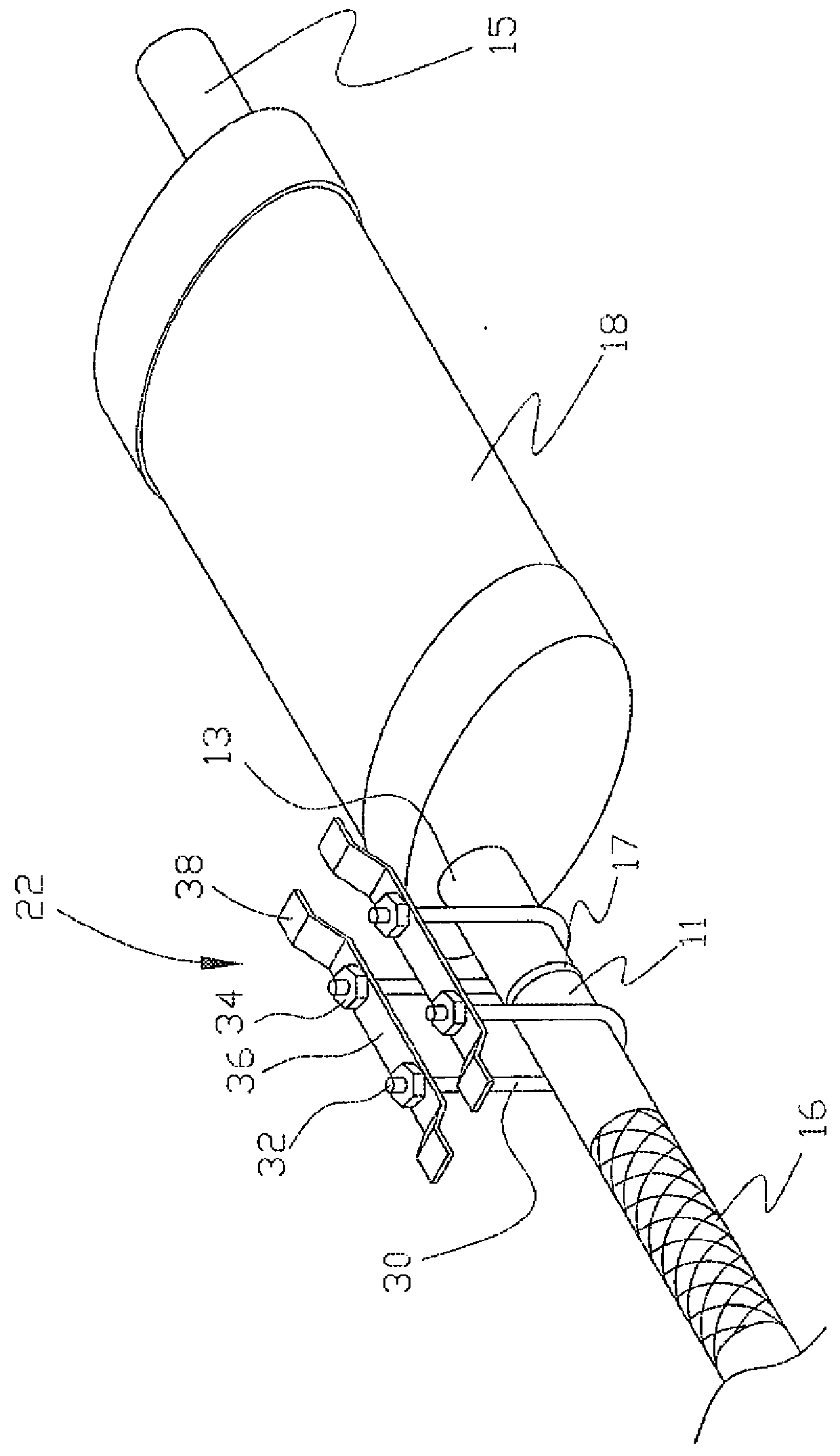

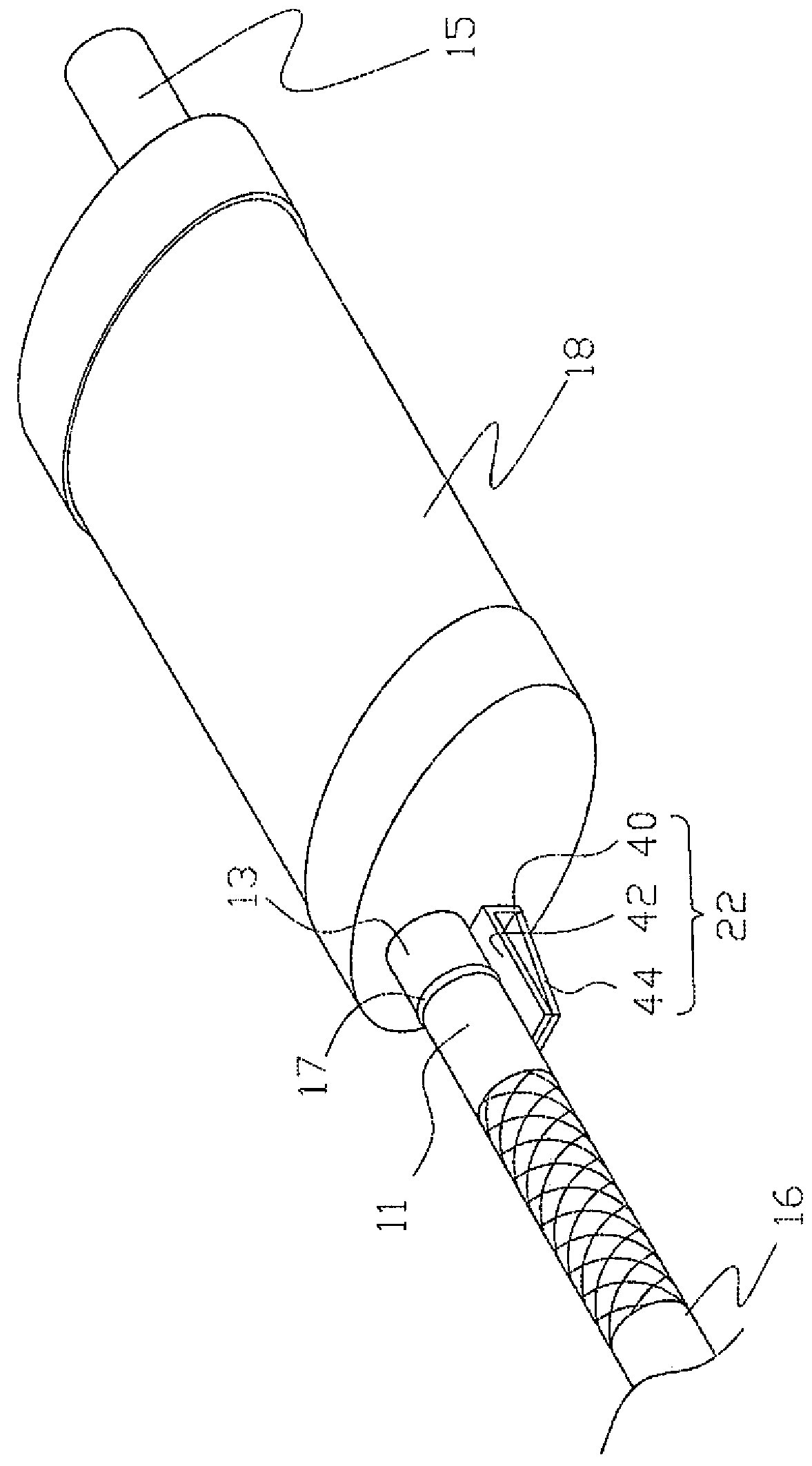

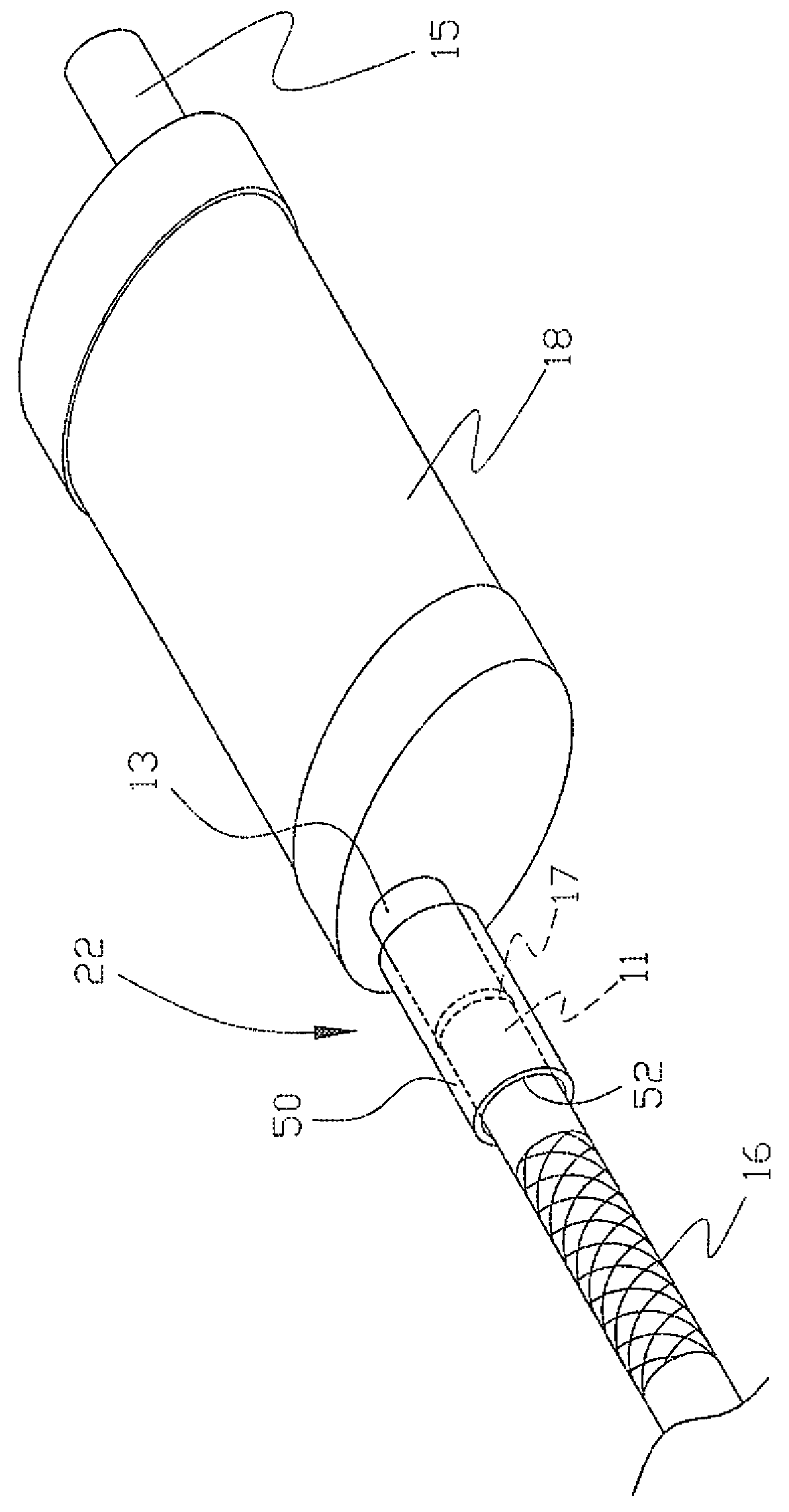

[0029]FIG. 1 shows a specific structure of a support unit 22 according to the first embodiment, which may be used in an exhaust system 10 for a vehicle in conjunction with the exhaust manifold 12, the pipe 20, the catalytic converter 14, the resonator 16 and the muffler 18 of FIG. 7.

[0030]In the drawing, the support unit 22 is composed of two U-shaped rods 30 and two combination sheets 36. Each U-shaped rod 30 has two screw sections 32. The screw sections 32 are formed on different ends of the U-shaped rod 30, and several nuts 34 are screwed to the corresponding screw sections 32. Each combination sheet 36 has an arched configuration and two ends defined with fixing portions 38. Each fixing portion 38 is welded to the bottom portion of the vehicle, so that the combination sheet 36 is kept in a fixed state. The two screw sections 32 pass through the middle portion of the combination sheet 36, which is blocked by the nuts 34 to support the two U-shaped rods 30 on two sides of a weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com