Compressor

a compressor and compressor technology, applied in the field of compressors, can solve the problems of increasing the amount of refrigerant to be compressed together with the amount of refrigerant to be discharged, and achieve the effects of reducing oil loss, increasing the flow rate of refrigerant inside the compressor, and high operation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

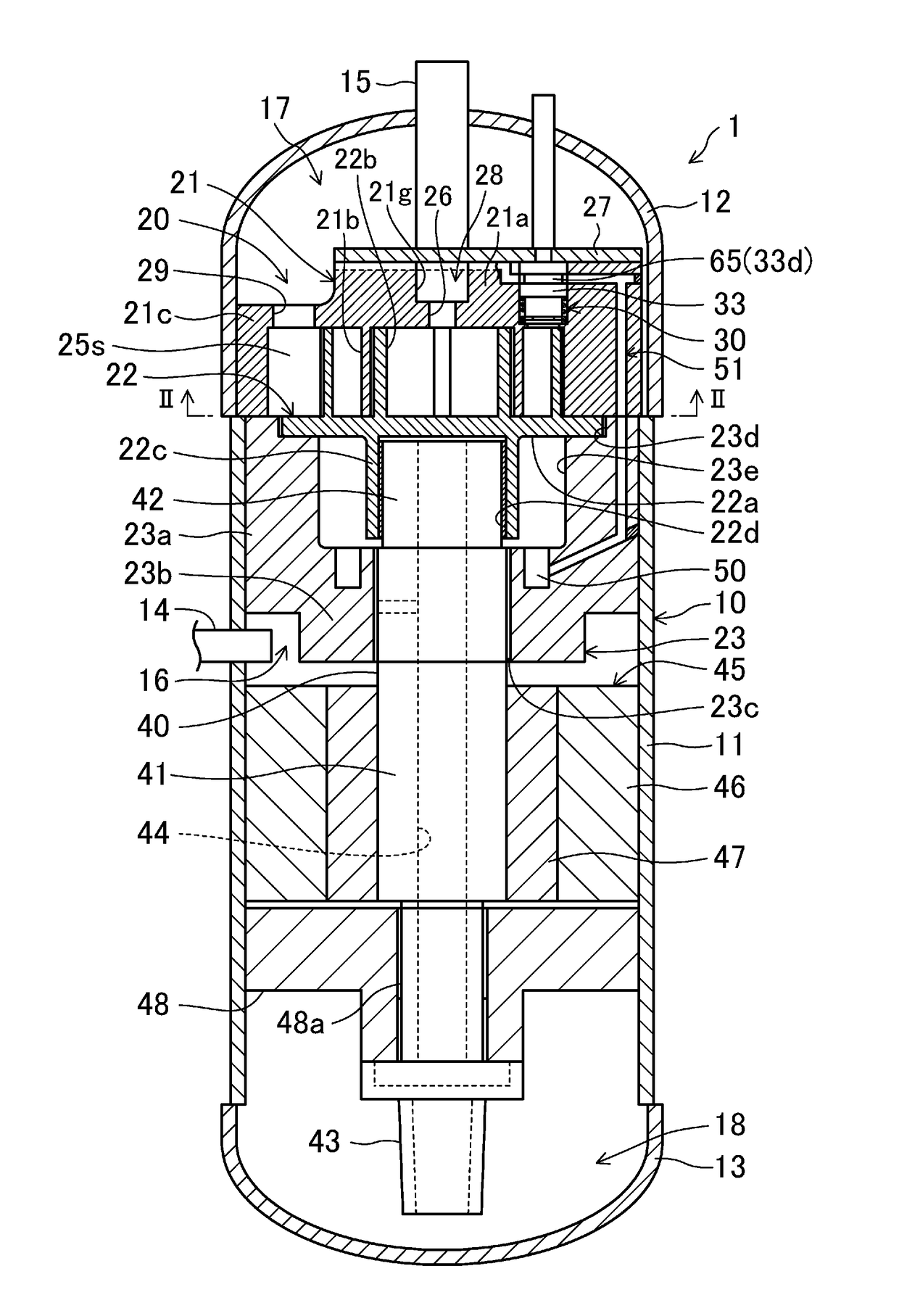

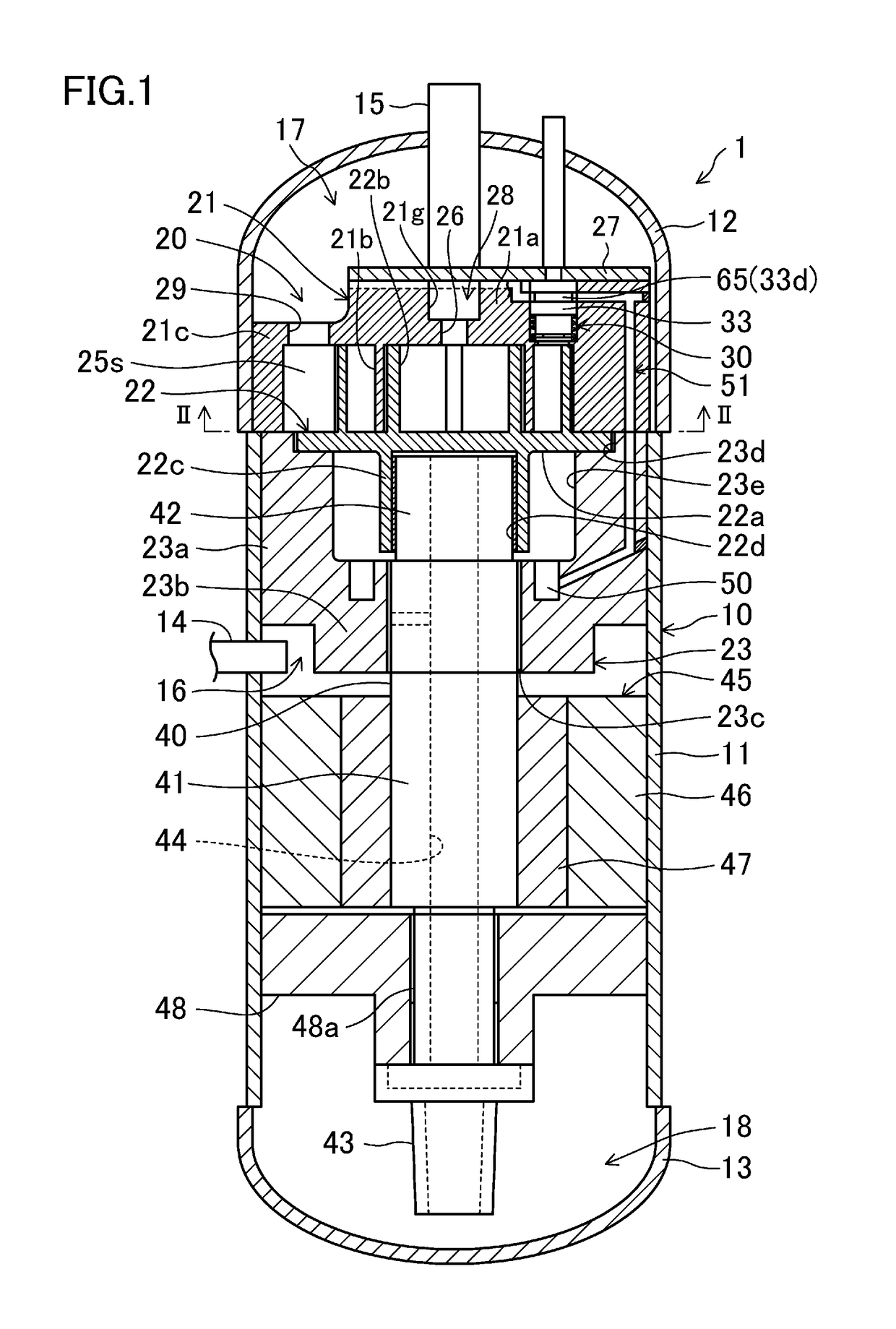

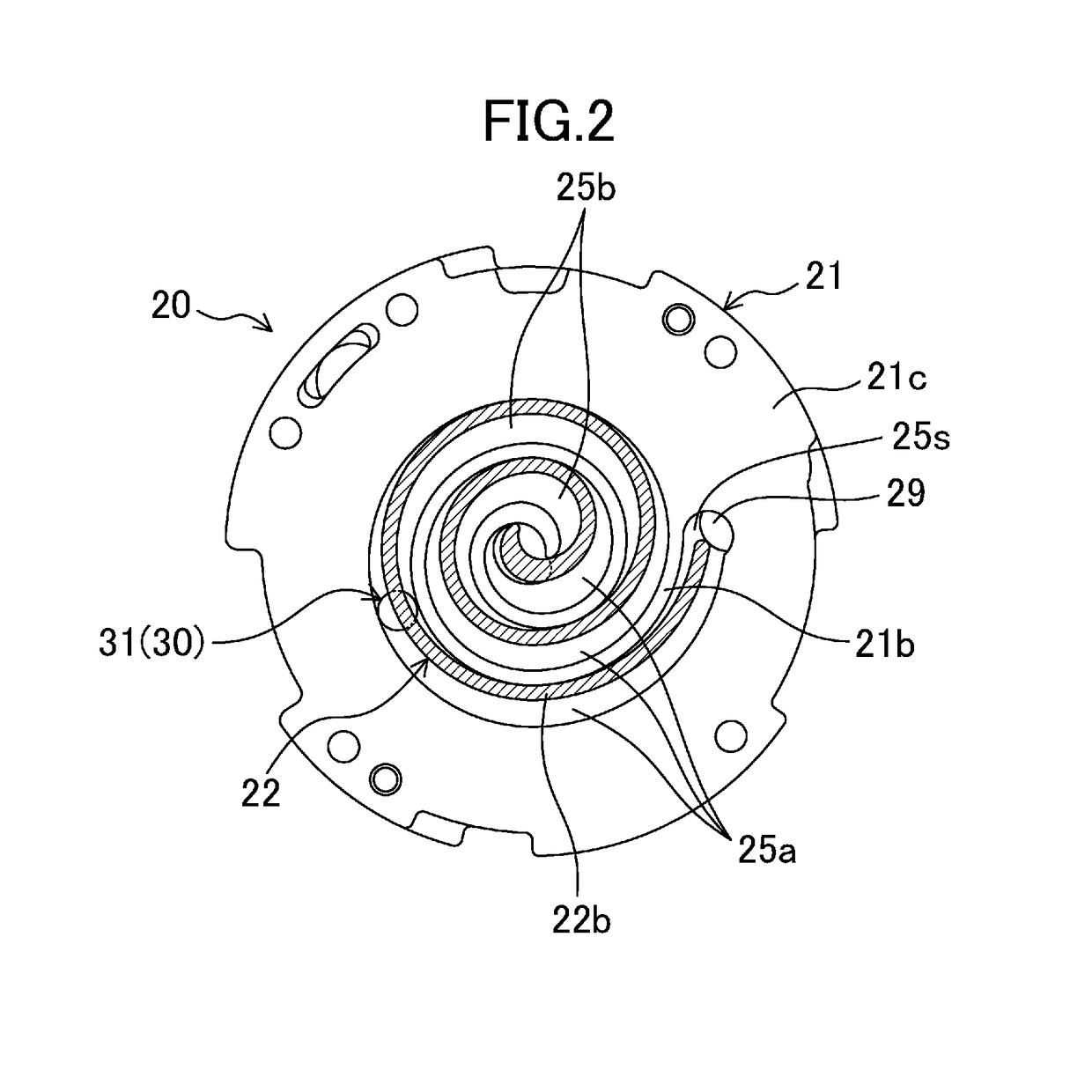

first embodiment

Variation of First Embodiment

[0114]As shown in FIGS. 13 and 14, the oil passage (51) may include a passage (fixed scroll inner passage (53)) entirely passing through the inside of the fixed scroll (21) to communicate with the plunger (33) and the suction space (25s) of the compression mechanism (20). In this variation, the suction pipe (14) is connected to the suction port (29), and the transverse passage (53) of the oil passage (51) communicates with the suction port (29). Such a configuration allows the oil in the oil reservoir (50) to mix with the suction refrigerant and to be supplied to the compression chamber (25).

[0115]According to this variation, if only the adjustment operation at the low operation capacity is performed, oil is not sufficiently supplied to the compression chambers (25a, 25b), and the oil film having a thickness necessary for the compression mechanism is less likely to be formed, resulting in performance degradation. However, in this variation, if the oil pa...

second embodiment

[0116]Next, a second embodiment will be described.

[0117]In the second embodiment, as shown in FIGS. 15 and 16, the oil passage (51) includes an oil passage (55) closer to the orbiting scroll (hereinafter referred to as “the orbiting-scroll-side oil passage (55)”), and an oil passage (52) closer to the fixed scroll (hereinafter referred to as “the fixed-scroll-side oil passage (52)”) communicating with the orbiting-scroll-side oil passage (55). The orbiting-scroll-side oil passage (55) has one end communicating with the fixed-scroll-side oil passage (51), and the other end opposite to one end and communicating with the oil reservoir (18). Specifically, the end of the orbiting-scroll-side oil passage (55), which is opposite to one end communicating with the fixed-scroll-side oil passage (52), communicates with the oil reservoir (18) in the lower portion of the casing (10) through the oil supply passage (44) formed inside the drive shaft (41). An end of the fixed-scroll-side oil passag...

third embodiment

[0119]Next, a third embodiment will be described.

[0120]In the third embodiment, as shown in FIG. 17, the oil passage (51) has one end communicating with the oil reservoir (18) formed inside the casing (10), and the other end communicating with the suction space (25s) of the compression mechanism (20). Specifically, the oil passage (51) has an oil supply pipe (56) extending upward from the oil reservoir (18) inside the casing (10) and communicating with the plunger (33). This oil supply pipe (56) communicates with the transverse passage (53). In the oil passage (51), a space (the transverse passage (53)) between the plunger (33) and a suction side of the compression chamber (25) is the same as, or similar to, that of the variation of the first embodiment and the second embodiment.

[0121]The other configuration of this embodiment is the same as, or similar to, that of the second embodiment.

[0122]According to this third embodiment, if only the adjustment operation at the low operation c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap