Integrated electronic device with a redistribution region and a high resilience to mechanical stresses

a technology of integrated electronic devices and mechanical stresses, applied in the direction of solid-state devices, electric devices, basic electric elements, etc., can solve problems such as stress, and achieve the effect of high thermal budg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

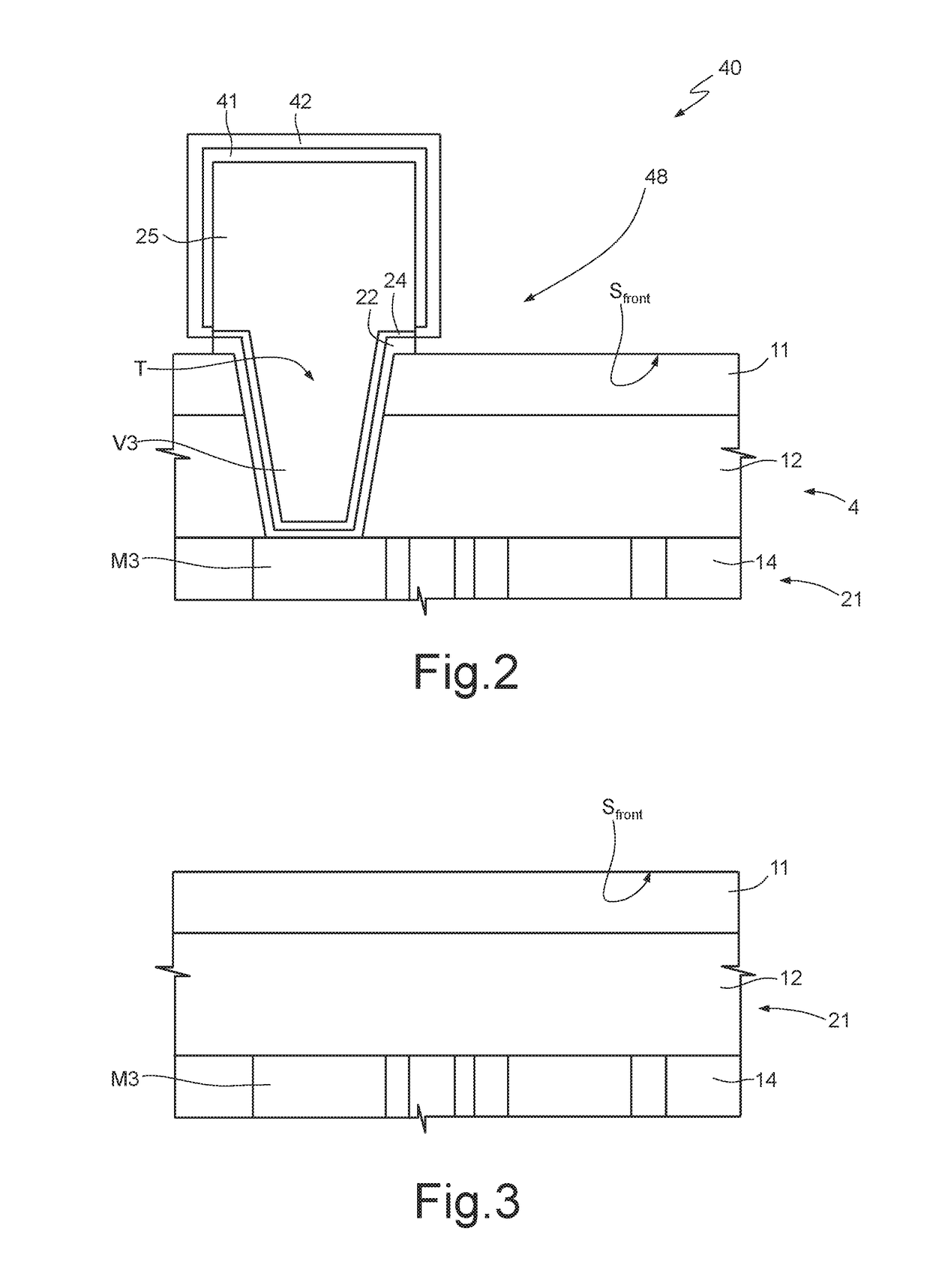

[0037]the present integrated electronic device is shown in FIG. 2, where it is indicated with 40. In particular, FIG. 2 shows only an upper portion of the integrated electronic device 40, given that the elements disposed underneath the third dielectric layer 14 are not shown.

[0038]This having been said, the first coating layer, here indicated with 41, covers the top and the sides of an upper portion of the redistribution layer 25 and is disposed at a distance from the first dielectric layer 11, i.e., it is physically separated from the latter. Furthermore, the first coating layer 41 is physically separated from the first patterned barrier layer 22 and from the patterned seed layer 24, given that it extends at the bottom to a height which is higher than the maximum height reached by the patterned seed layer 24. Consequently, the first coating layer 41 leaves a lower portion of the redistribution layer 25 laterally exposed, together with portions of the patterned seed layer 24 and of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thicknesses | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com