Blade Sharpener

a blade and blade technology, applied in the field of blade sharpeners, can solve the problems of impractical approach to repetitive sharpening operations of different blades, unwieldy adjustment, and inability to quickly and easily accommodate sharpening devices, and achieve the effect of efficient blade sharpening operations, easy operation and unwieldy adjustmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]Reference will now be made in detail to the presently preferred embodiments of the invention. There are also representative examples of the invention illustrated in the accompanying drawings. Throughout the following detailed description, the same reference numeral refers to the same elements in all figures.

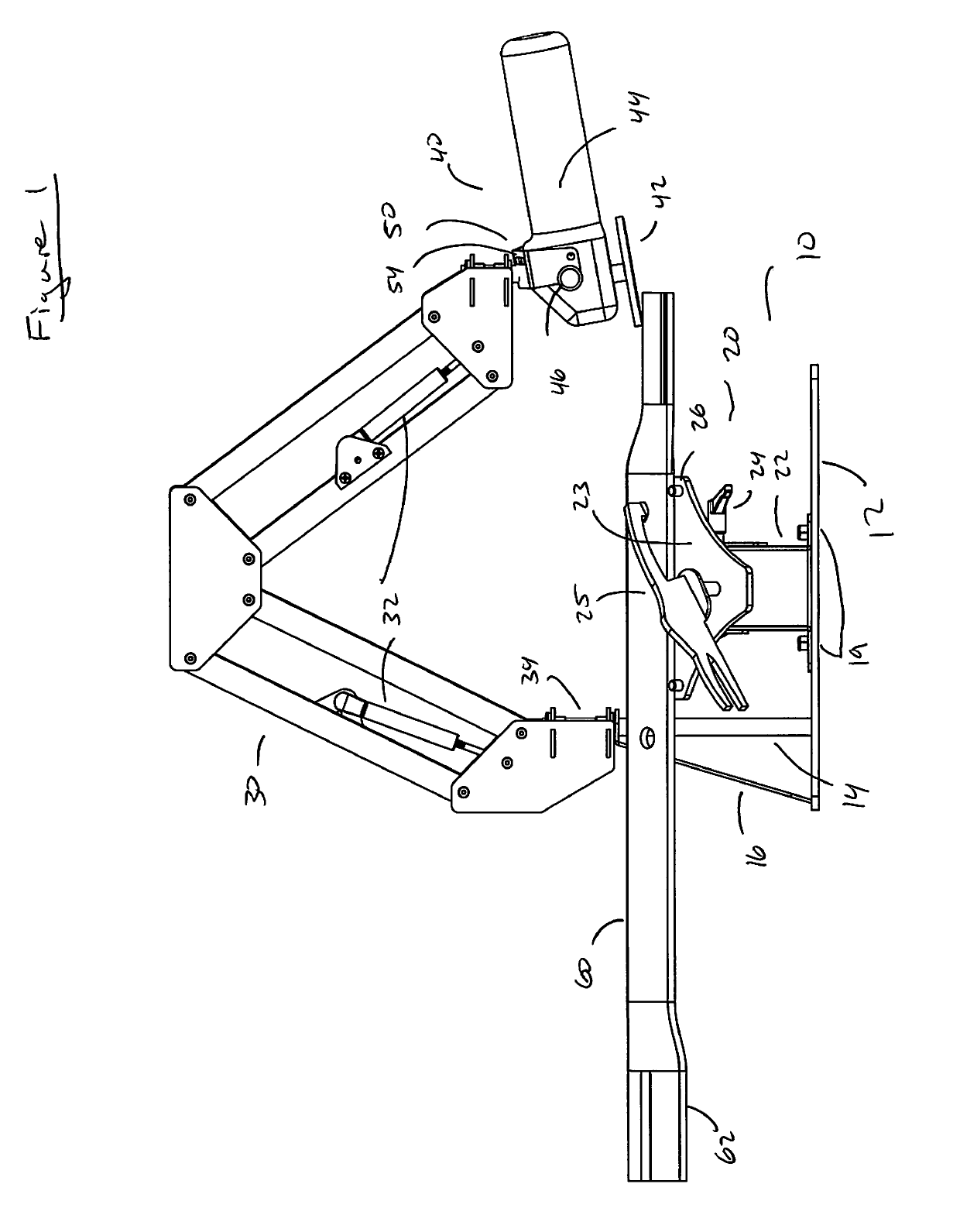

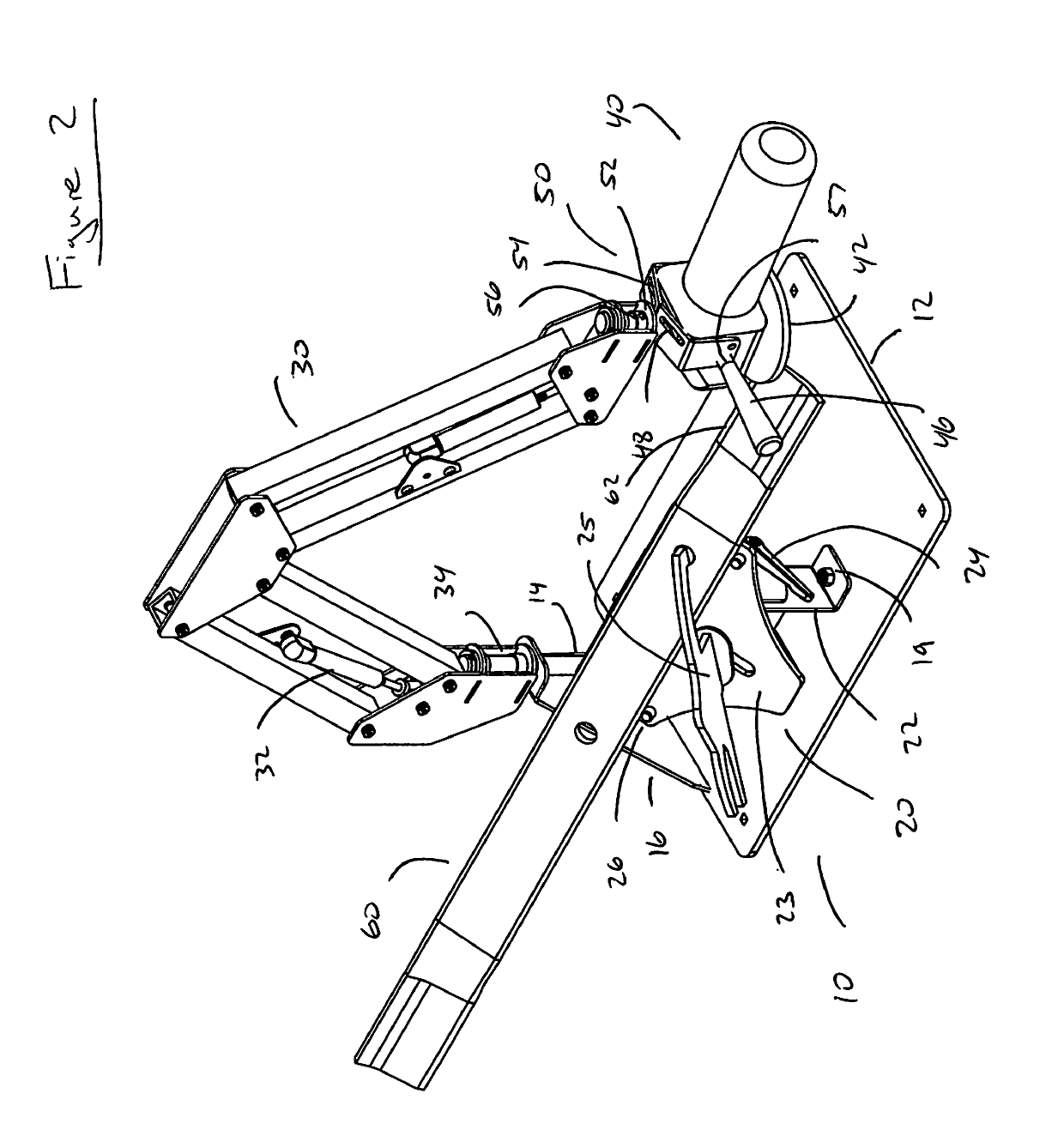

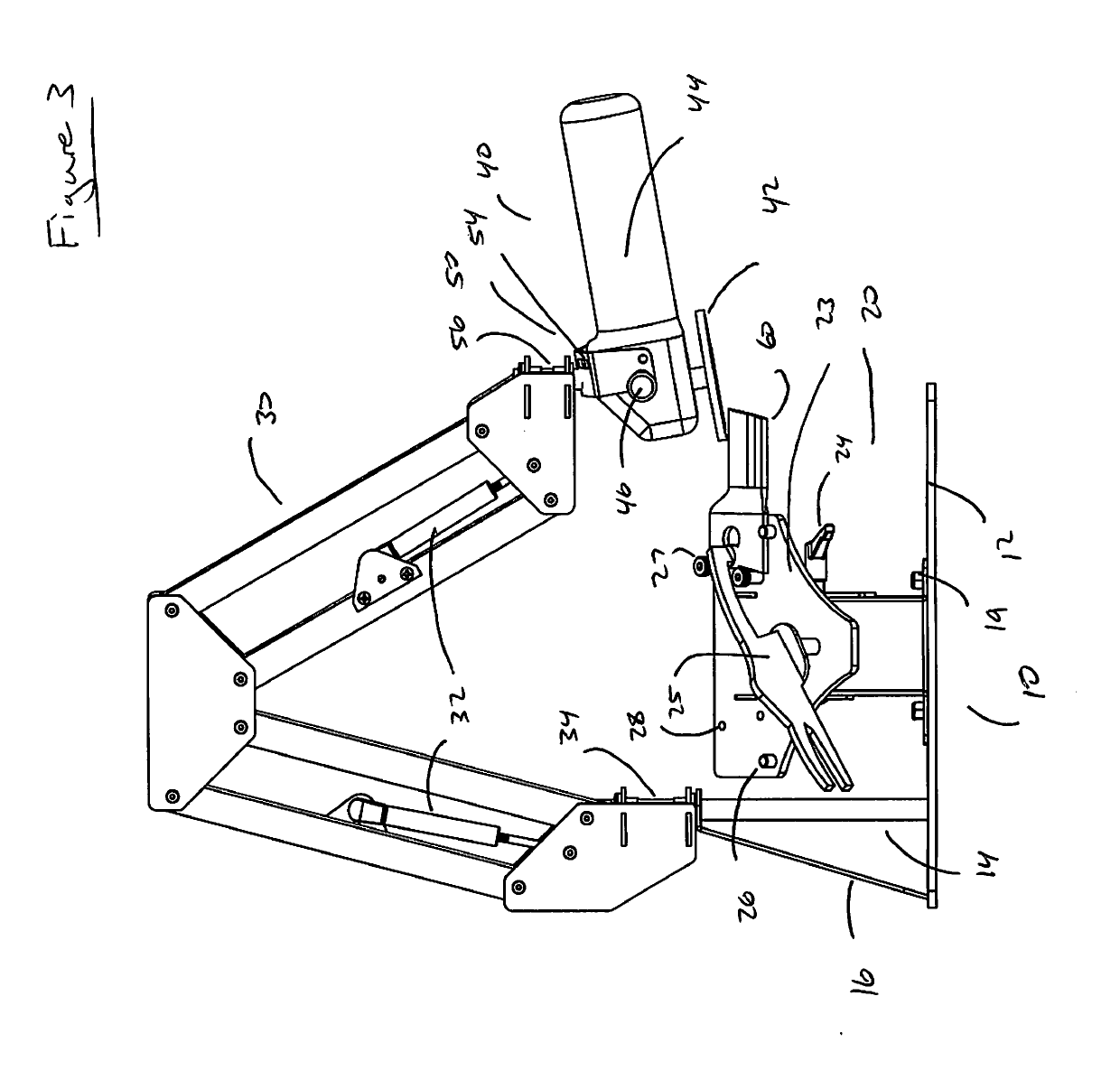

[0019]Now referring to the drawings, and first to FIG. 1, a blade sharpener in accordance with the present invention is illustrated. The blade sharpener comprises a base 10 that supports the unit during operation. Base 10 comprises a base plate 12 that is preferably a flat piece of metal that can provide stability to the unit during operation. In an optional embodiment, legs (not shown), can be attached to base plate 12 so the unit can be placed directly on a floor. When base plate 12 is not attached to legs, the unit can be placed on a desk, bench, or other supporting surface that is in direct contact with the base plate. Base 10 further comprises post 14 and riser 16. Pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| set angles | aaaaa | aaaaa |

| set angles | aaaaa | aaaaa |

| sharpening angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com