Packing material including cushion

a cushion and packaging technology, applied in the field of cushioning, can solve the problems of increasing the quantity difficulty in downsizing, and difficulty in recycling, and achieve the effects of increasing the number of components, reducing the number of disposed packing materials, and high buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Hereinafter, one or more embodiments of the present invention will be described with reference to the drawings. However, the scope of the invention is not limited to the disclosed embodiments.

[0023]The following describes an embodiment of the present disclosure, with reference to the drawings.

[Appearance of Image Forming Device]

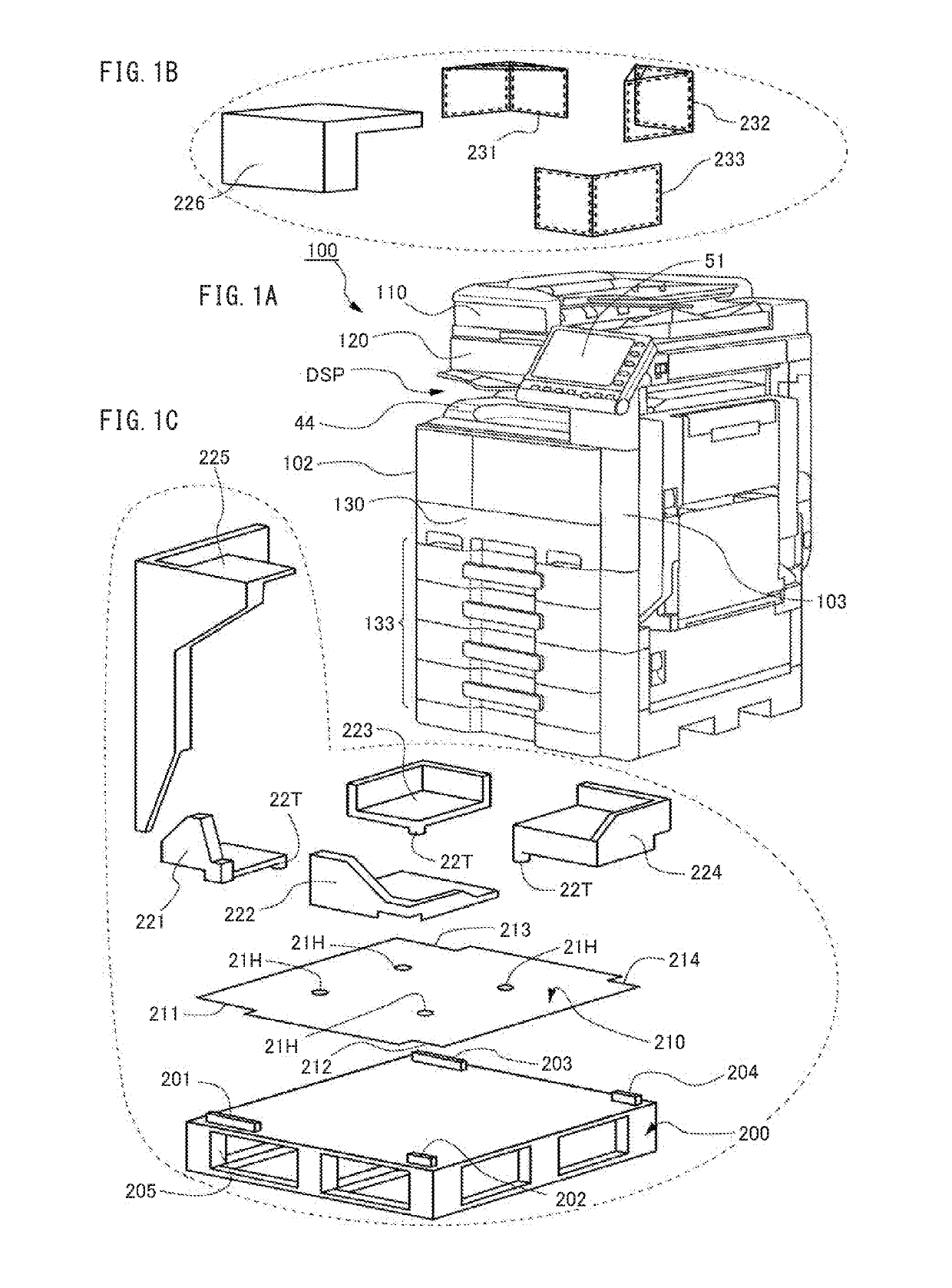

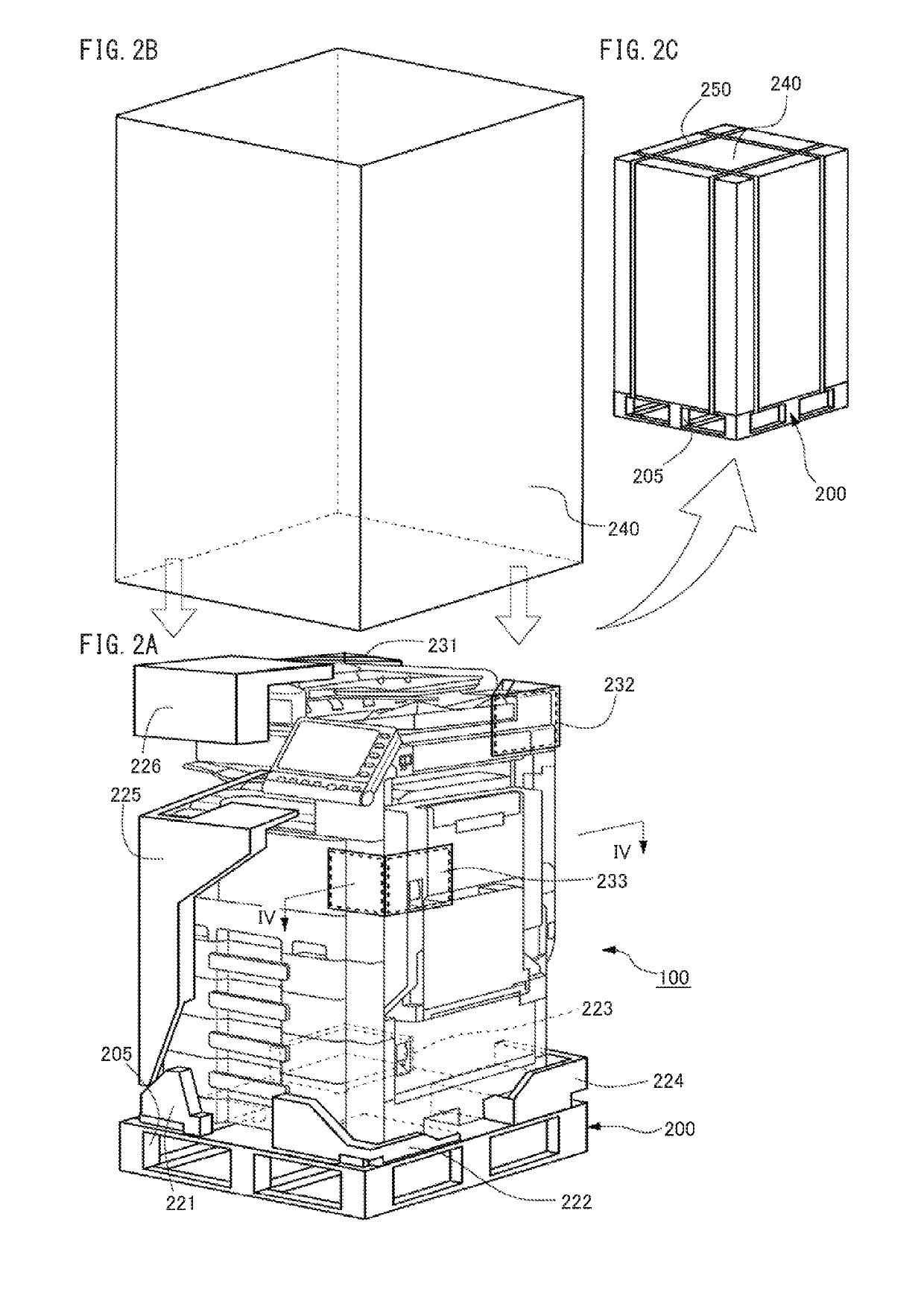

[0024]FIG. 1A is a perspective view of an appearance of an image forming device to be packed. The image forming device 100 is an in-body sheet-ejection type multi-function peripheral (MFP) that has functions of a scanner, a color copier, and a color printer. On an upper face of a housing containing the MFP 100, the MFP 100 has an auto document feeder (ADF) 110 that is mounted in an openable and closable manner. At an upper portion of the housing immediately below the ADF 110 is contained a scanner 120; at a lower portion of the housing is contained a printer 130; and at a bottom portion below the printer 130, the MFP 100 has a plurality of paper cassett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com