Method for manufacturing gallium nitride substrate using the multi ion implantation

a gallium nitride and multi-ion implantation technology, which is applied in the manufacture of basic electric elements, semiconductor/solid-state devices, electrical equipment, etc., can solve the problems of reducing mechanical strength, unable to form self-supporting substrates, and high fabrication costs of gan substrates or inp substrates. , to achieve the effect of reducing the defect ratio of gallium nitride substrates, low defect density and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

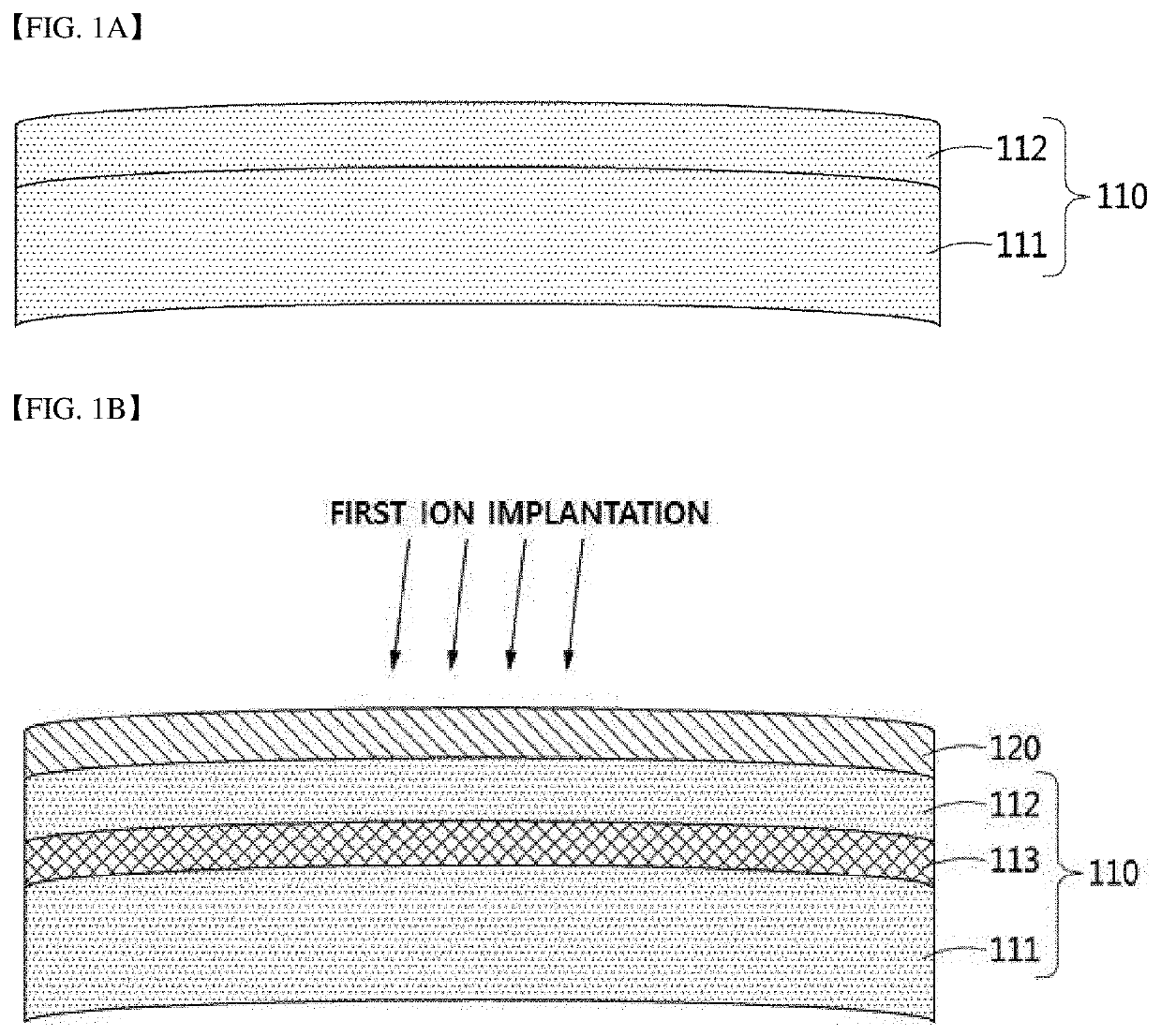

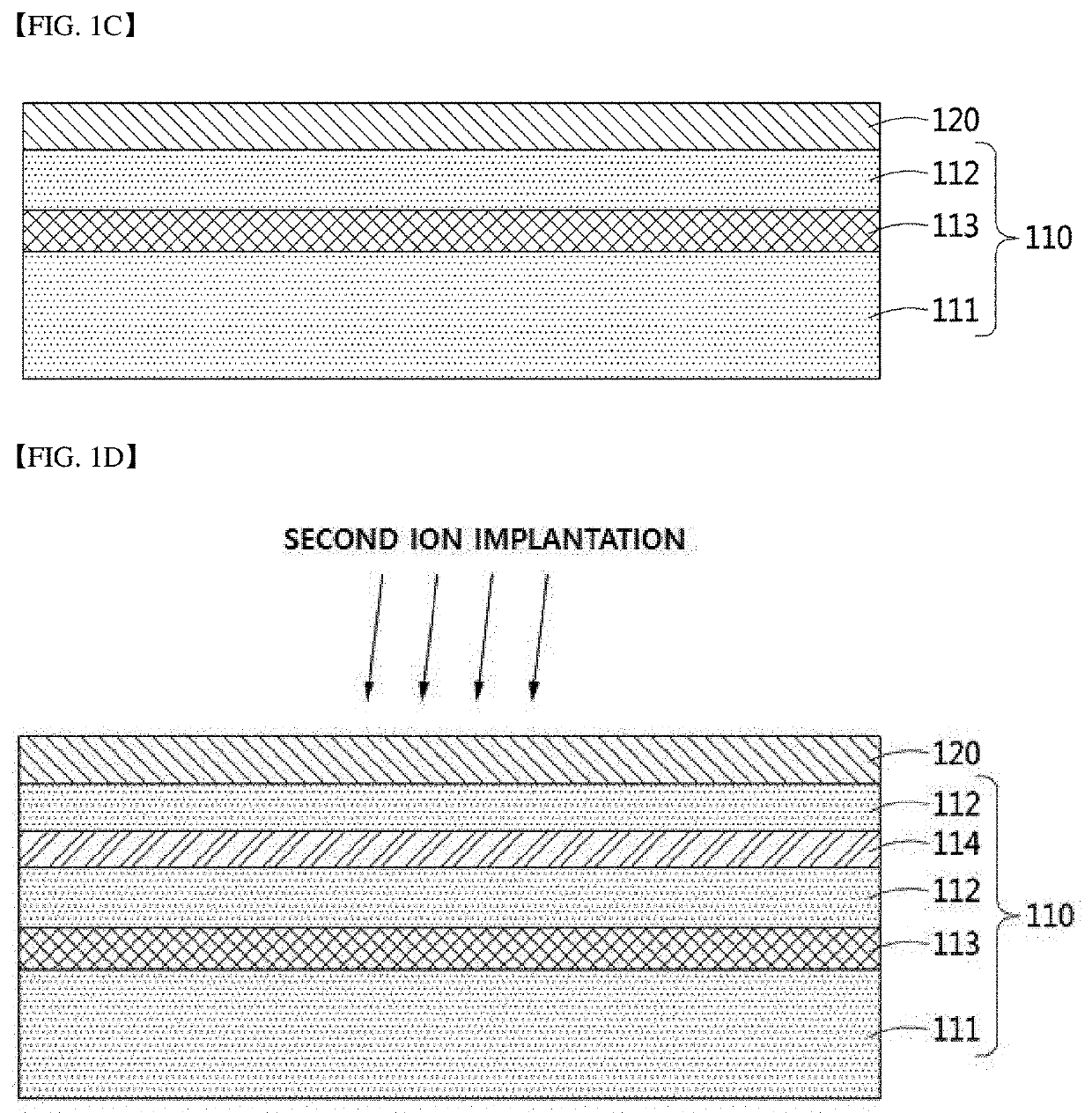

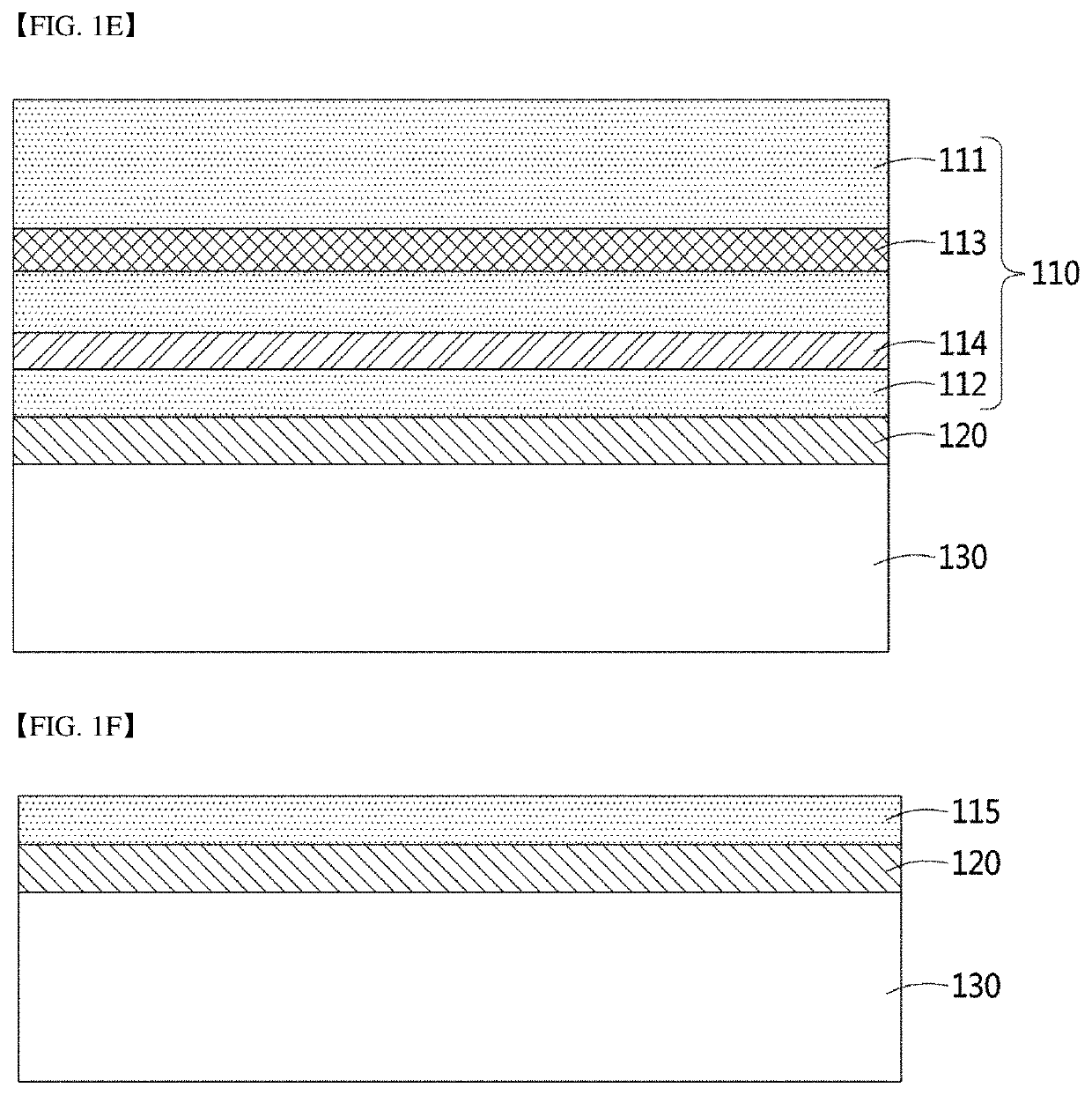

[0039]The present disclosure will now be described more fully with reference to the accompanying drawings and contents disclosed in the drawings. However, the present disclosure should not be construed as limited to the exemplary embodiments described herein.

[0040]The terms used in the present specification are used to explain a specific exemplary embodiment and not to limit the present inventive concept. Thus, the expression of singularity in the present specification includes the expression of plurality unless clearly specified otherwise in context. It will be further understood that the terms “comprise” and / or “comprising”, when used in this specification, specify the presence of stated components, steps, operations, and / or elements, but do not preclude the presence or addition of one or more other components, steps, operations, and / or elements thereof.

[0041]It should not be understood that arbitrary aspects or designs disclosed in “embodiments”, “examples”, “aspects”, etc. used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com