Firearm trigger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

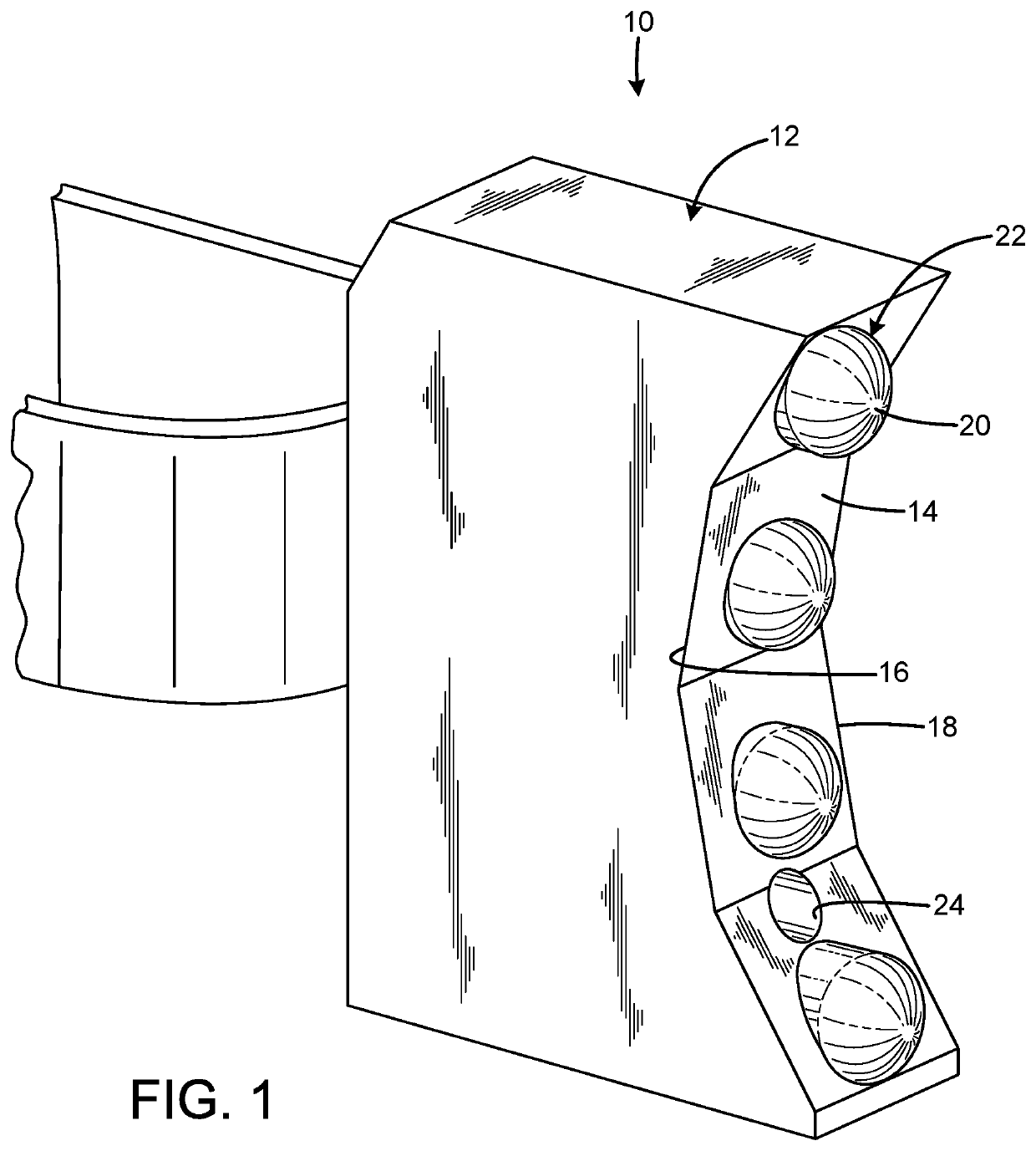

[0014]An embodiment of the firearm trigger of the present invention is shown and generally designated by the reference numeral 10.

[0015]FIG. 1 illustrates the improved firearm trigger 10 of the present invention. More particularly, the firearm trigger is suitable for use with a 1911 pistol. The firearm trigger has a trigger body 12 that includes an elongated forward actuation surface 14 with opposed edge portions 16, 18. The forward actuation surface includes four spaced-apart protrusions 20 that are arranged in an elongated array / column 22 along the length of the forward actuation surface and defines a forward-facing aperture 24. The protrusions are spaced apart from each other by portions of the forward actuation surface. In the current embodiment, the protrusions are convex hemispheres, round, positively curved surfaces, surfaces of revolution, and have a vertical dimension along the length of the forward actuation surface and a perpendicular lateral dimension equal to the vertic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap