Galvanically decorated component and method for producing a galvanically decorated component

a technology of galvanic decoration and component, applied in the direction of superimposed coating process, liquid/solution decomposition chemical coating, coating, etc., can solve the problems of increasing the cost of the additional work step, the symbol produced from metal does not demonstrate sufficient strength against wear and corrosion, and the cost is significantly increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

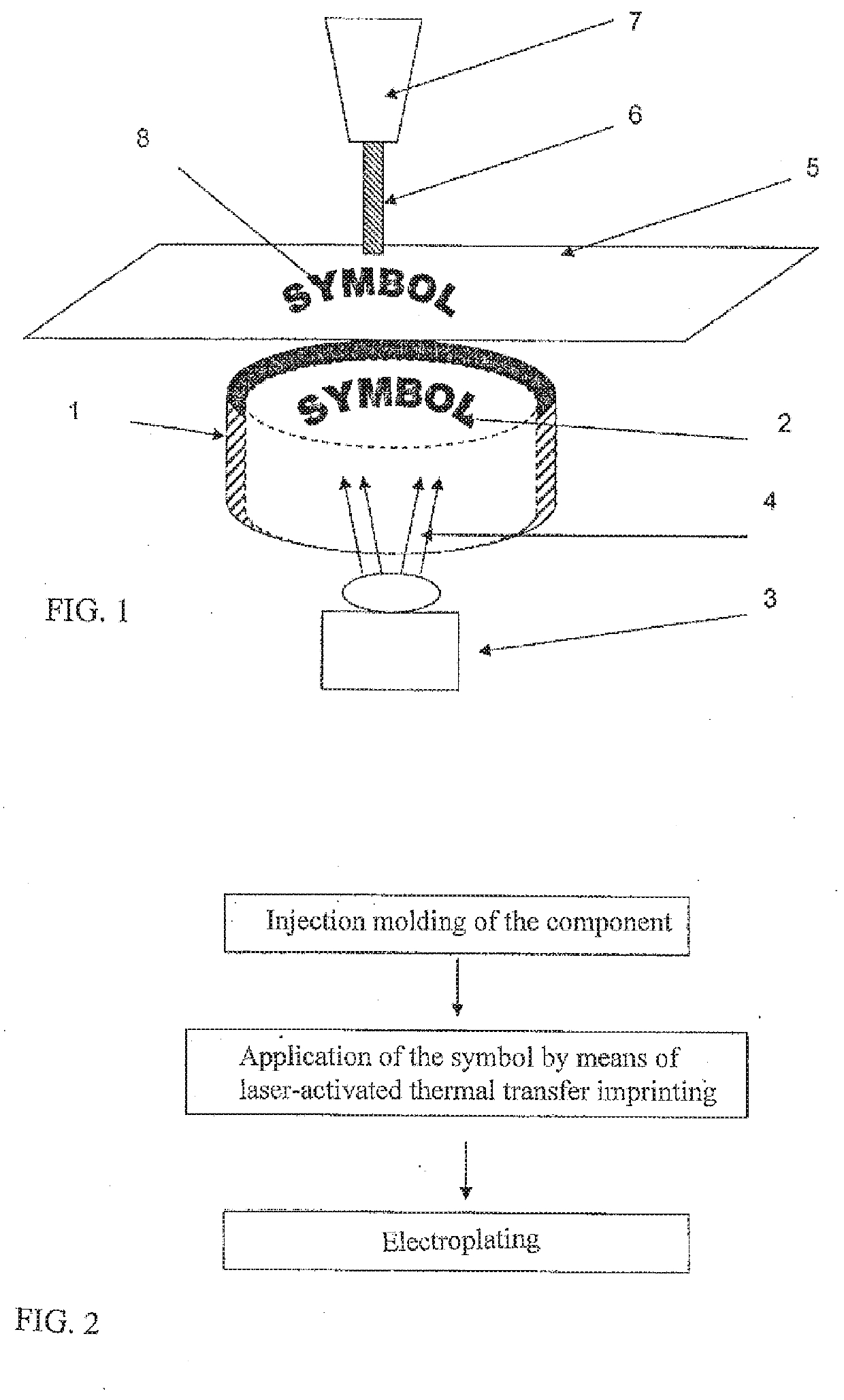

[0020]The coated component 1, shown as an exemplary embodiment, shows a product produced from plastic for the automotive industry, with subsequent electroplating. The component 1, after completion of the method, has a symbol 2, which can be both pictograms and numbers, words or the like.

[0021]In the exemplary embodiment according to FIG. 1, a start / stop button for an automobile is described, with which the engine of the automobile can be started and shut off again. In this case, the symbol consists of the words “start,”“stop,” and “engine.” If other operating elements are involved, the symbol is generally formed in the form of a pictogram, for example the representation of a headlight, if an operating element for vehicle lighting is involved.

[0022]In the method according to the exemplary embodiment according to FIG. 2, first the component to be produced from plastic is produced using the injection-molding method. The plastic is preferably a plastic that can be electroplated, prefera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| translucent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com