Closure Cap For A Detergent Bottle

a detergent bottle and closure cap technology, applied in the field of detergent bottle closure caps, can solve the problems of closure caps breaking, unable to rule out the possibility of relatively great forces or impacts on the bottle, and no longer be guaranteed that the detergent bottle will stay upright, etc., and achieve the effect of avoiding surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

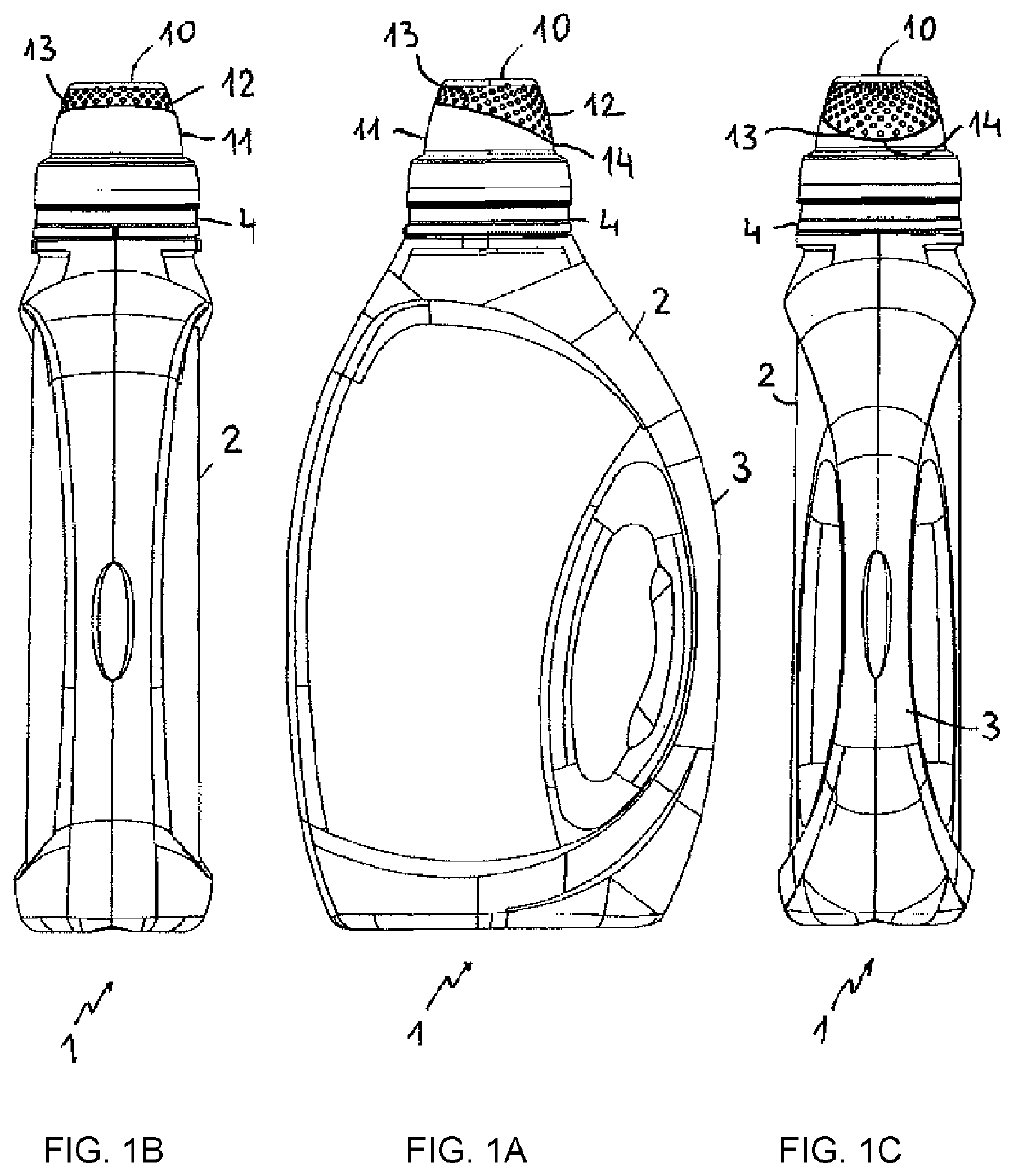

[0024]FIG. 1 shows a detergent bottle 1 in three different views. FIG. 1A shows the container in a front view, FIG. 1B shows the container in a first side view and FIG. 1C shows the container in a second side view. The detergent bottle 1 comprises a main body 2, which defines an interior space for receiving the liquid detergent. The volume of the interior space can be, for example, from 500 ml to 5000 ml. In the embodiment shown, a handle 3 is molded into one side of the main body 2.

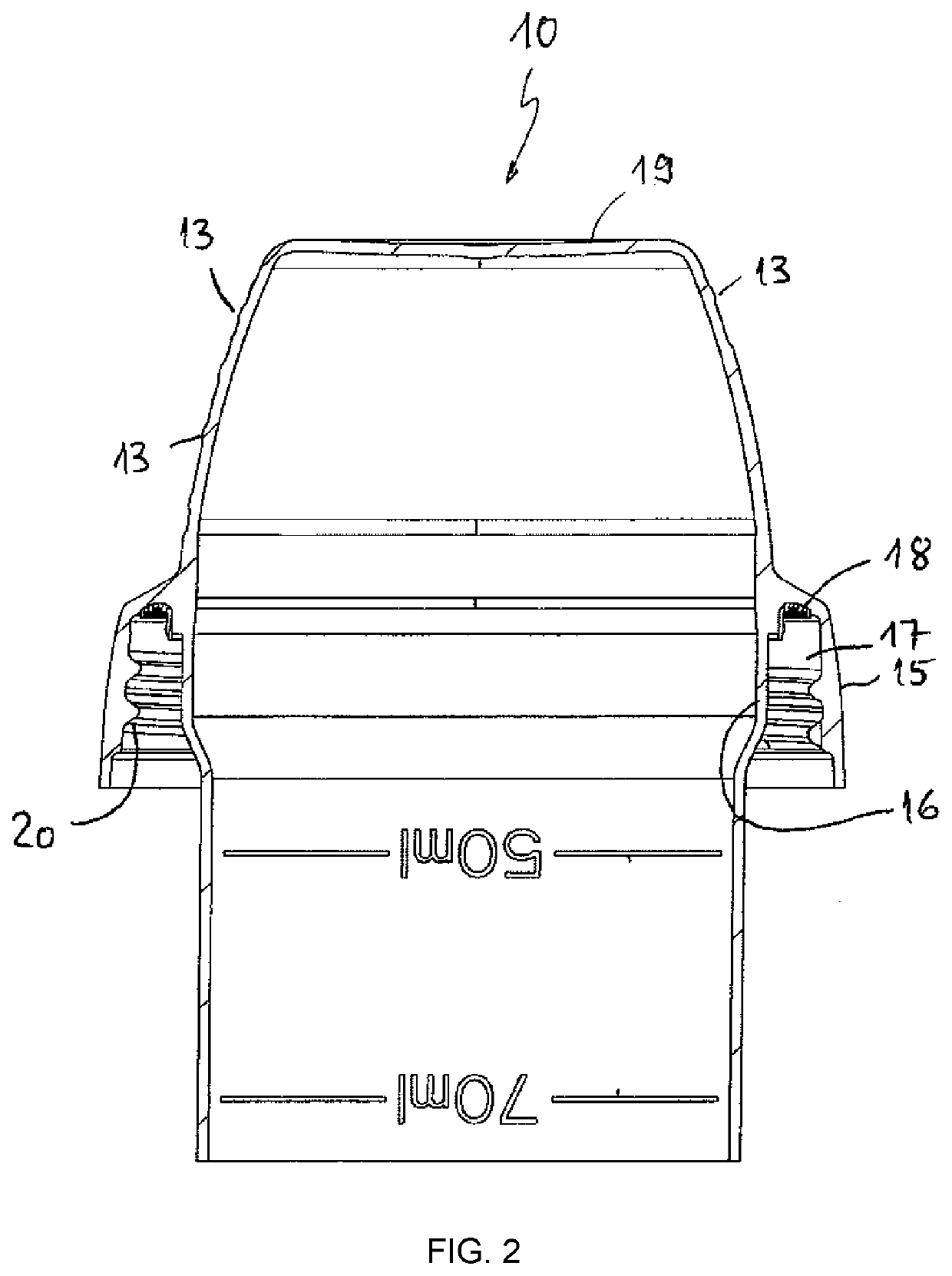

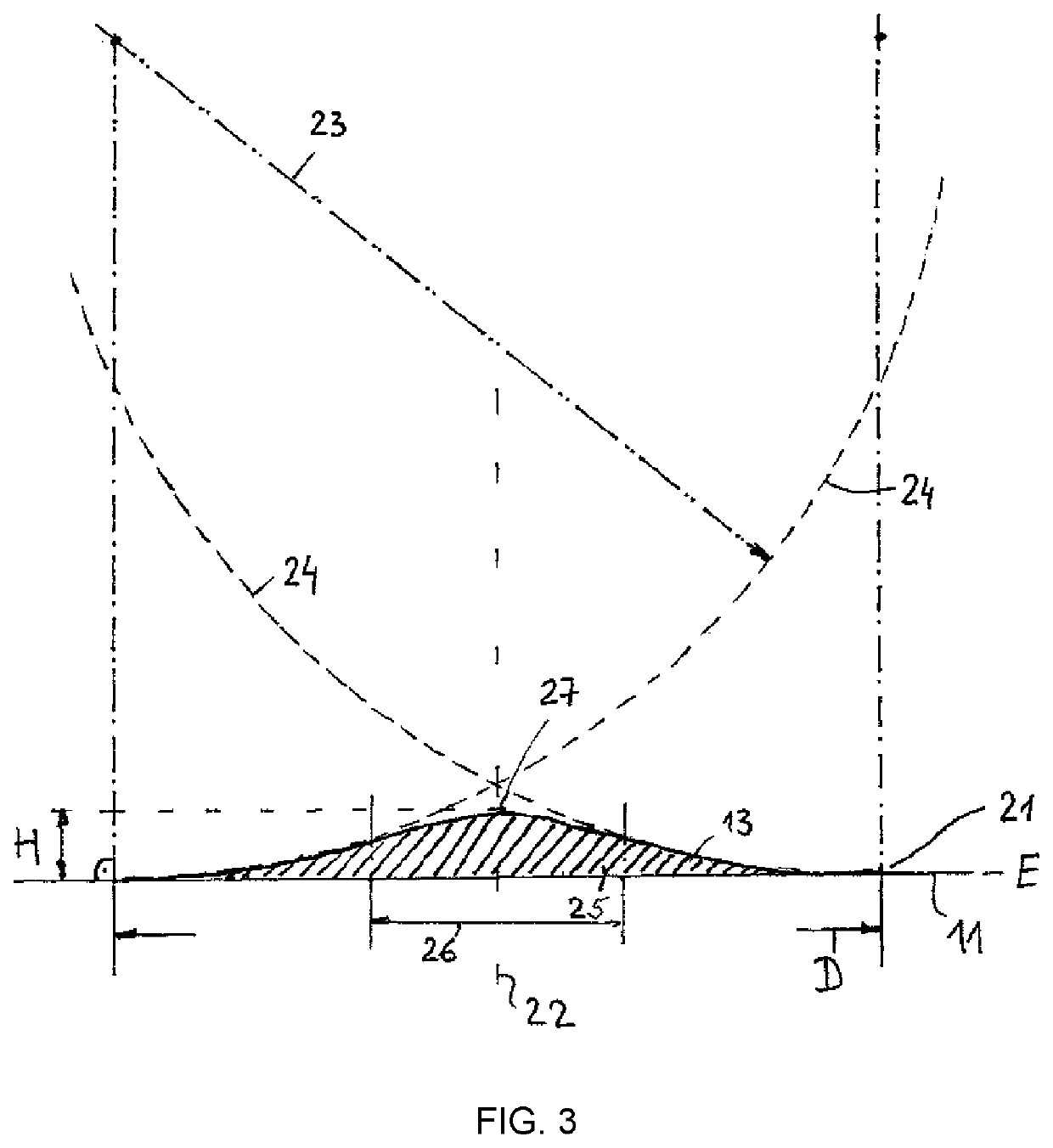

[0025]A closure cap 10 is placed on an upper end of the main body 2. The closure cap 10 has a cylindrical basic shape. A region 12 having circular surface elements 13 is provided on a slightly conical cap wall 11, which represents a lateral face of the cylindrical basic shape. As a result, the closure cap 10 can be used to effectively rub the detergent into particularly heavily soiled regions of the laundry to be cleaned. Furthermore, the surface elements 13 facilitate the handling of the closure cap 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com