Sound attenuation for material handling systems

a material handling and sound attenuation technology, applied in the field of sound attenuation in material handling systems, can solve the problems of inherently loud receptacles or totes for handling and transporting articles and materials, material handling operations that produce significant noise, deleterious health effects for workers and operators inside the material handling facility, etc., to reduce vibration, reduce vibration, and reduce vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

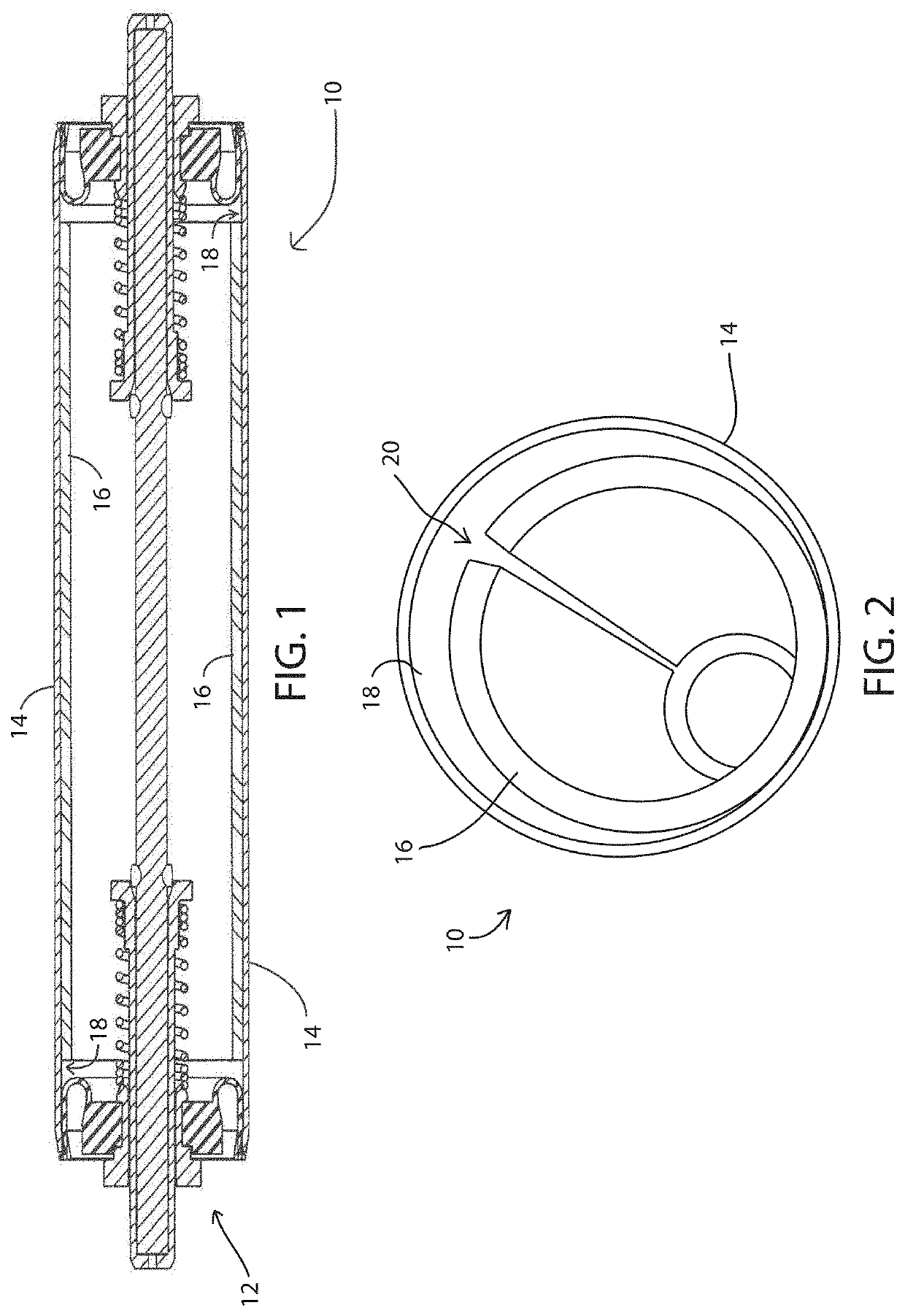

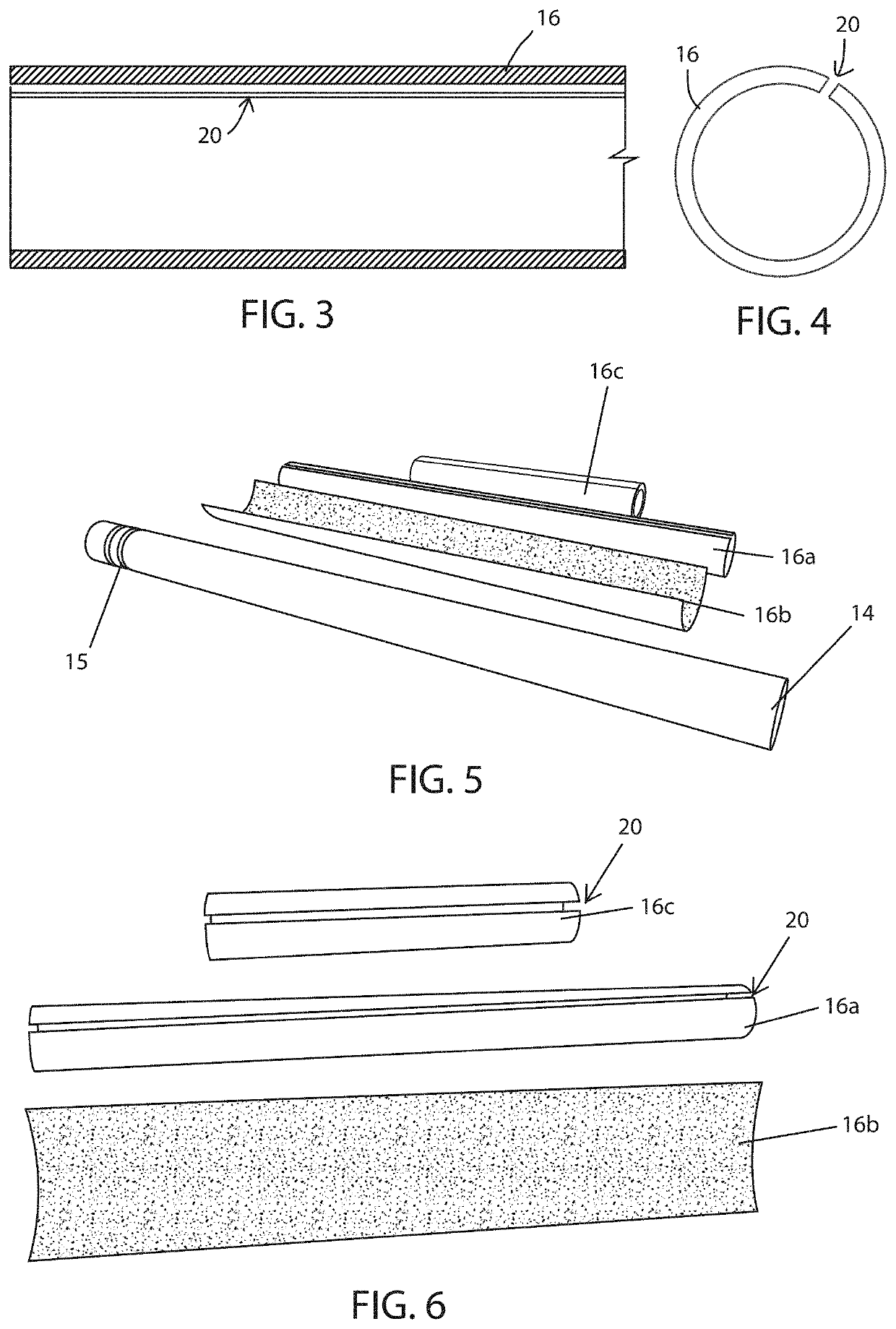

[0029]Referring now to the drawings and the illustrative embodiments depicted therein, a sound attenuated or damped roller apparatus 10 and a sound attenuated or damped material handling tote or bin 110 are provided for reducing sound during operation of conveyor type material handling systems, such the sound produced as a tote 110 moves along a conveyor roller system. In the illustrated embodiments of FIGS. 1-6, the roller apparatus 10 includes a conveyor roller assembly 12 with a metal roller, casing, or tube 14 defining an exterior roller surface for supporting articles (e.g. totes, receptacles, boxes, or individual items) as they are transported along the conveyor roller system (FIGS. 1-2). A sound damper 16, such as a sound damping material, is disposed on the interior of the roller 14. The roller apparatus 10 may be provided with new conveyor systems or for retrofit applications to sound-attenuate rollers in existing conveyor systems. In a preferred embodiment, the sound-atten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com