Elongated Smoking Article

a smoking article and elongation technology, applied in the field of elongated smoking articles, can solve problems such as filtering capacity, and achieve the effects of improving the user experience of smoking heated tobacco products, and reducing the risk of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

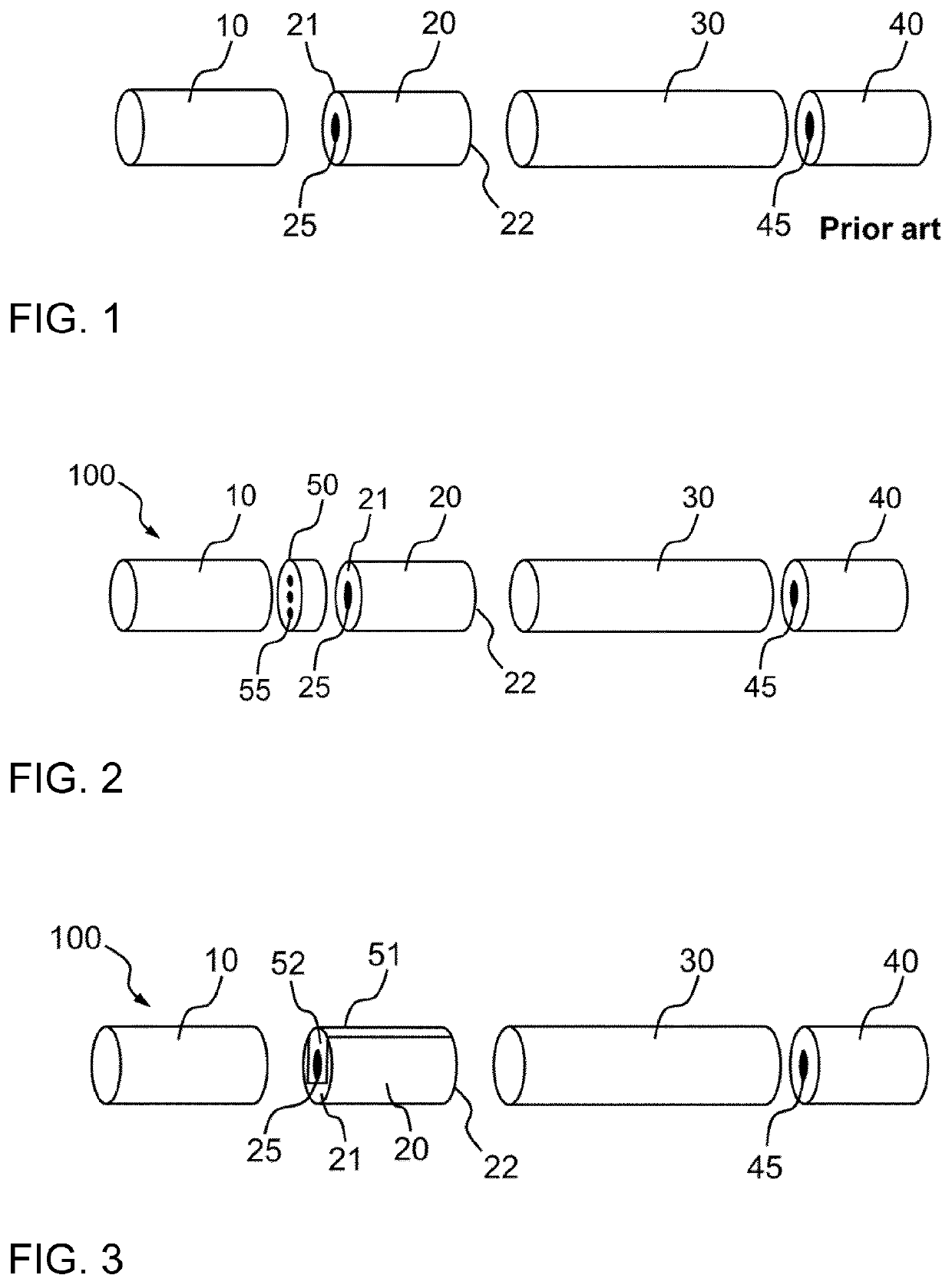

[0093]FIG. 2 illustrates a schematic perspective view of an elongated smoking article 100 according to the present disclosure. The elongated smoking article 100 of FIG. 2 differs of that from FIG. 1 in that a disc-shaped filter membrane 50 is positioned in between the smoking body 10 and the hollow bore filter element. The filter membrane is adhered to the first base area 21 of the hollow bore filter element 20 and / or wedged between the smoking body 10 and the hollow bore filter element 20 by indirect force closure due to the wrapping paper (not shown). The filter membrane 50 comprises a plurality of aperture openings 55 that are aligned with the hollow bore 25 of the hollow bore filter element 20 as schematically shown in FIG. 2. The function of the filter membrane 50 is described in detail with respect to FIG. 5 and a redundant description is thus omitted with respect to FIG. 2.

second embodiment

[0094]FIG. 3 illustrates a schematic perspective view of an elongated smoking article 100 according to the present disclosure. The elongated smoking article 100 of FIG. 2 differs of that from FIGS. 1 and 2 in that a first portion 51 of the filter membrane 50 is attached to a lateral surface of the hollow bore filter element 20. A second portion 52 of the filter membrane 50 is bent from the first portion 51 and over the first base area 21 of the hollow bore filter element 20. A plurality of aperture openings (not shown) are arranged in the second portion 52 and aligned, i.e., overlaid, with hollow bore 25. The filter membrane 50 is advantageously well attachable to the hollow bore filter element 20.

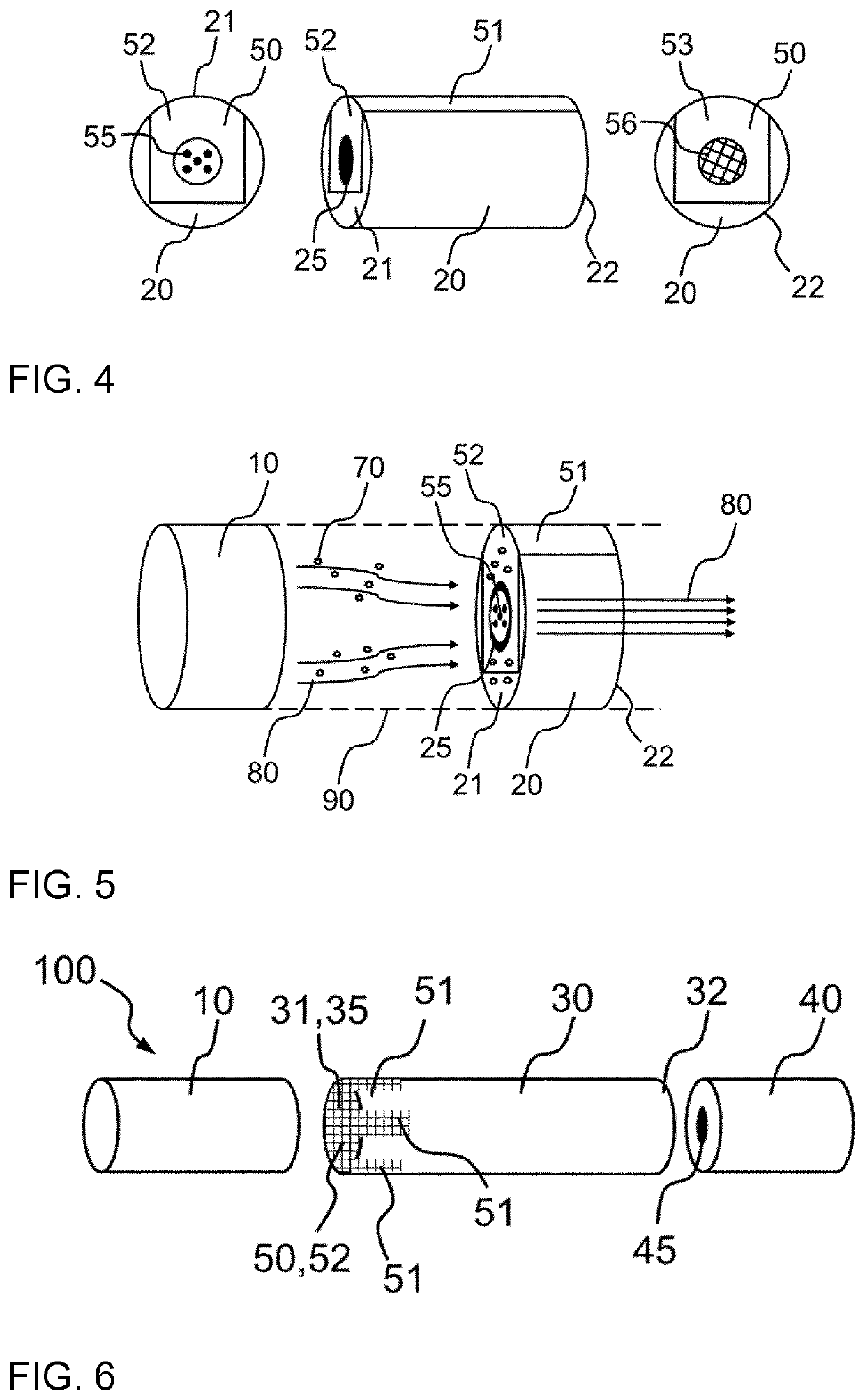

[0095]FIG. 4 illustrates a schematic perspective view of a hollow bore filter element 20 according to an embodiment and schematic front views of the base areas 21, 22, of such hollow bore filter element 20. The hollow bore filter element 20 has a first portion 51 of a filter membrane 50 at...

fourth embodiment

[0101]FIG. 9 illustrates a side view of an elongated smoking article 100 according to a Again, the elongated smoking article 100 comprises a smoking body 10 at the upstream end of the elongated smoking article 100. The smoking body 10 comprises reconstituted tobacco as combustible material 11 which includes nicotine as a volatile compound. The combustible material 11 comprises 65 wt % tobacco which is provided in the form of gathered shreds produced from a sheet of slurry / paper recon tobacco. The tobacco is dosed with 20 wt % of a humectant such as propylene glycol (PG) or vegetable glycerine (VG) and has a moisture content of between 7 to 9 wt %. The combustible material 11 further comprises cellulose pulp filler and guar gum binder. The smoking body 10 is formed in a substantially cylindrical shape such that the elongated smoking article 100 resembles a conventional cigarette. It has diameter of around 7 mm and an axial length of around 12 mm.

[0102]The smoking body 10 is circumsc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com