Composite material based building material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

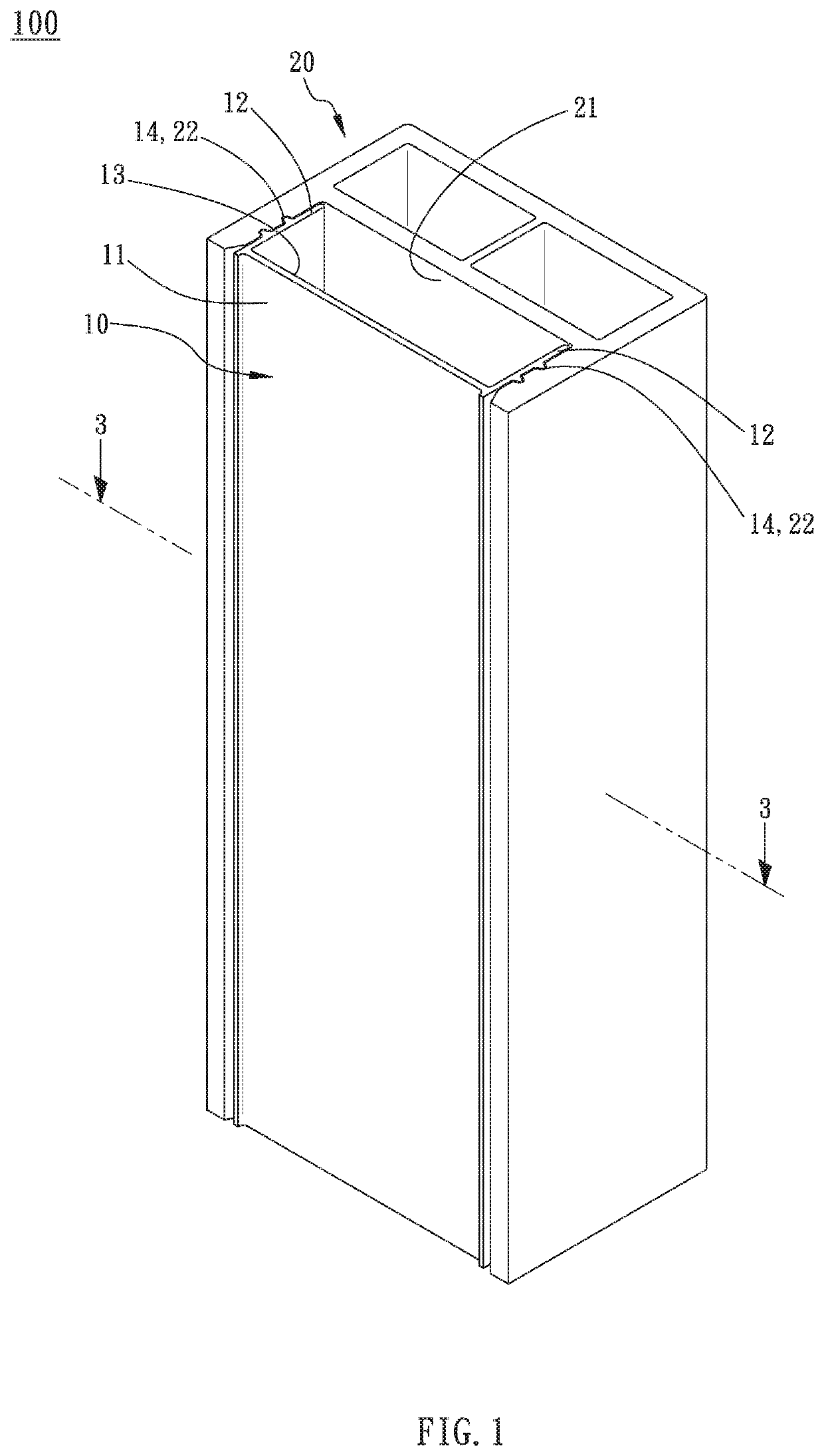

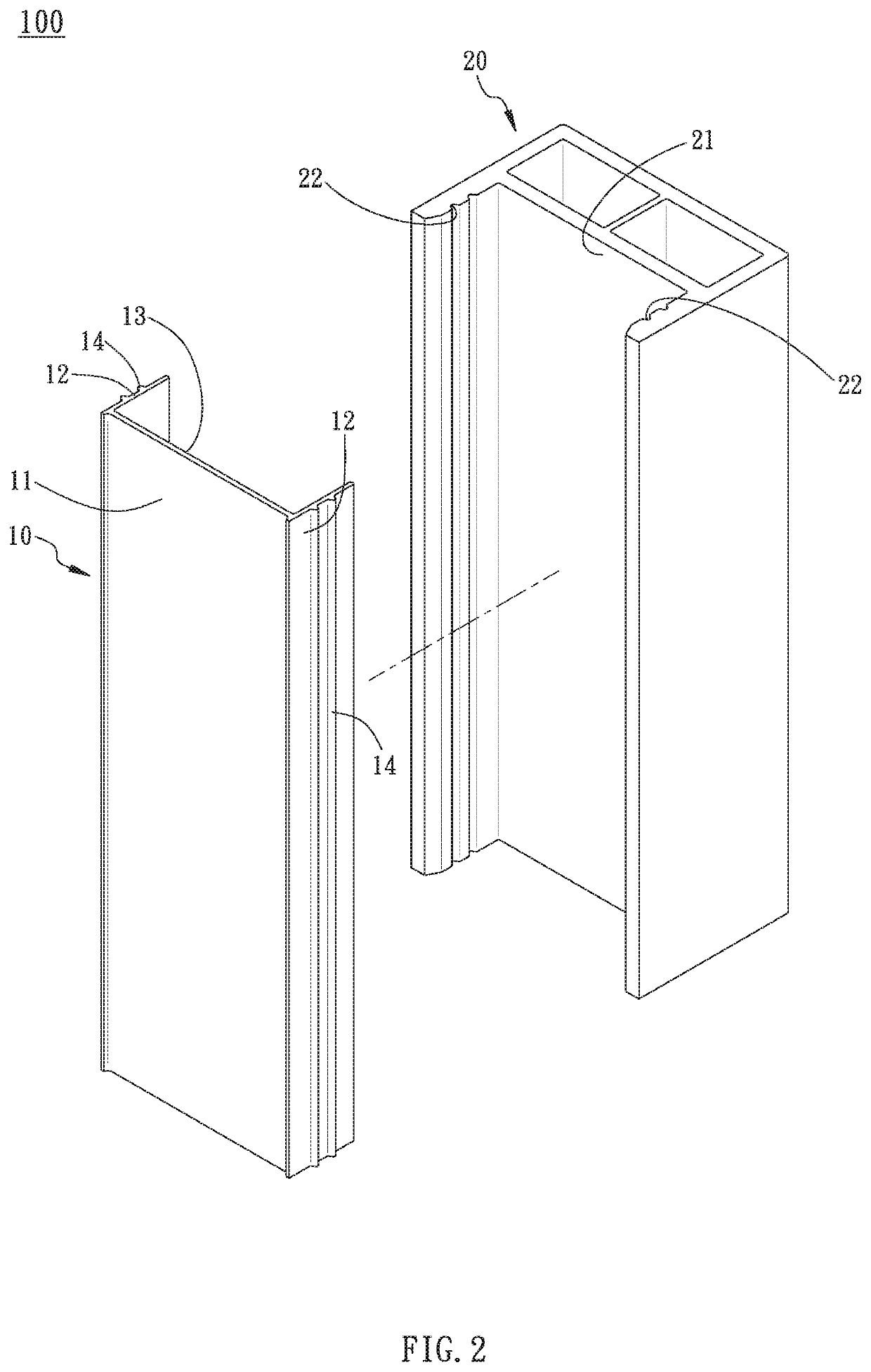

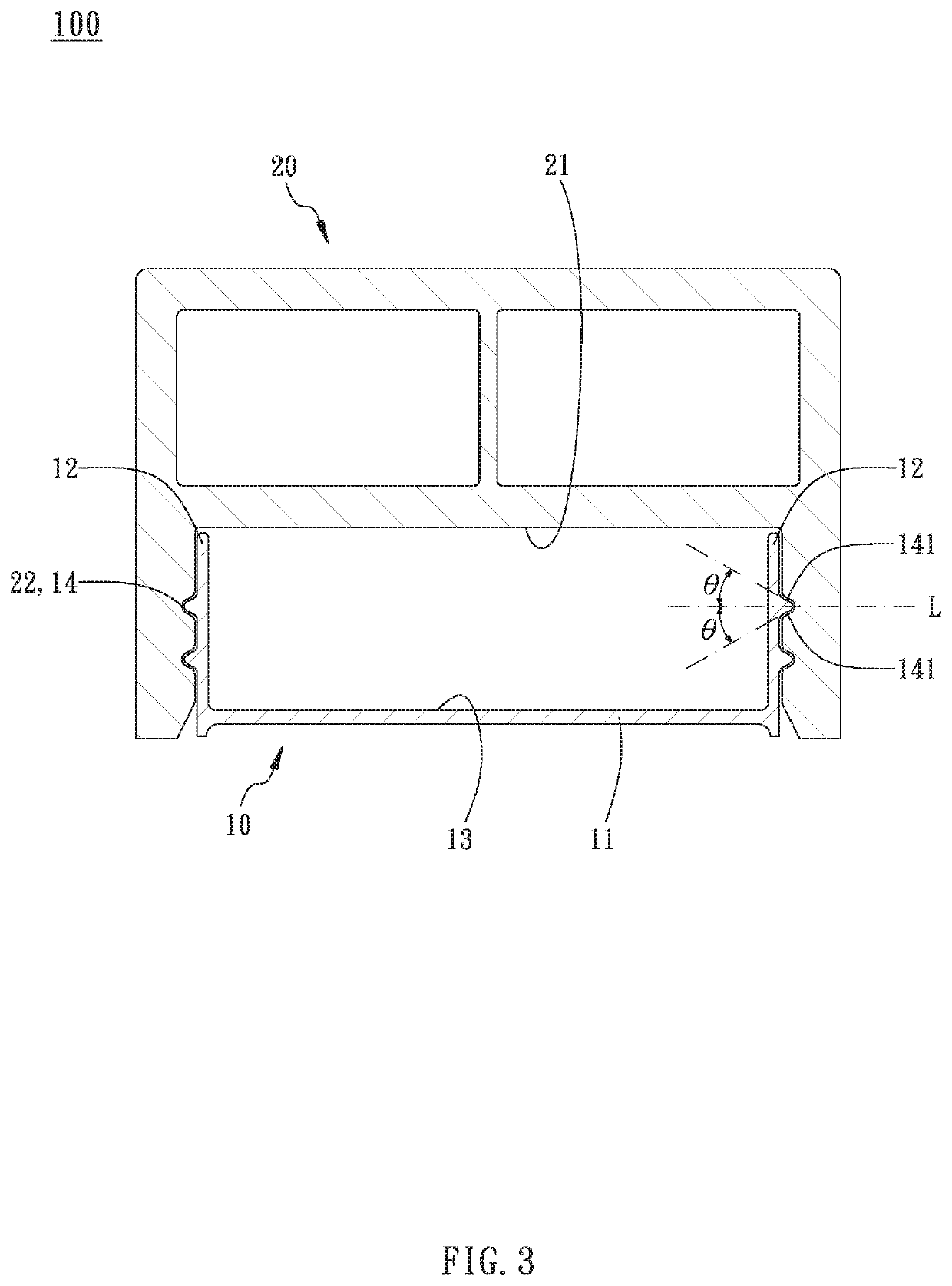

[0025]Referring to FIG. 1 to FIG. 4, in the present invention, a composite material based building material structure 100 comprises a metal member 10 and a combination member 20.

[0026]The metal member 10 is formed in a bar shape. In a preferred embodiment, the metal member 10 is an extrusion of aluminum alloy, with a surface thereof being anodized to form an antioxidant layer thereon, such that the metal member 10 possesses anti-corrosion property. In detail, the metal member 10 comprises a connection plate 11 and two lateral plates 12 disposed on two ends of the connection plate 11. The two lateral plates 12 extend toward an identical side of the connection plate 11, such that a combination groove 13 is formed by the connection plate 11 and the two lateral plates 12. Referring to FIG. 1 and FIG. 3, a sectional profile of the combination groove 13 is formed in a U shape, with one side thereof open and the other side thereof closed. The metal member 10 further comprises a plurality o...

third embodiment

[0036]The two fixation members 50′ are mounted on an outer side of each combination member 20′ and connected between the two neighboring combination members 20′. Referring to FIG. 9 and FIG. 10, each fixation member 50′ comprises a fixation portion 51′ and two positioning portions 52′ disposed on two sides of the fixation portion 51′. Each positioning portion 52′ extends toward one side of the fixation portion 51′. In the third embodiment, each fixation member 50′ is mounted on the combination members 20′ with fixation portion 51′ and positioning portion 52′ resisting against an outer periphery of combination member 20′, such that the two fixation members 50′ are close to and resist against each other, and each fixation portion 51′ is disposed perpendicular to an imaginary line D of each combination member 20′. Afterwards, a plurality of fasteners 53′ are applied on the positioning portion 52′ for fastening the fixation member 50′ with the corresponding combination member 20′, metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com