Ignition coil

a technology of ignition coil and coil body, which is applied in the direction of electric ignition installation, mechanical equipment, machines/engines, etc., can solve the problems of large expenditure, insufficient engine compartment space, and insufficient space above the cylinder bank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

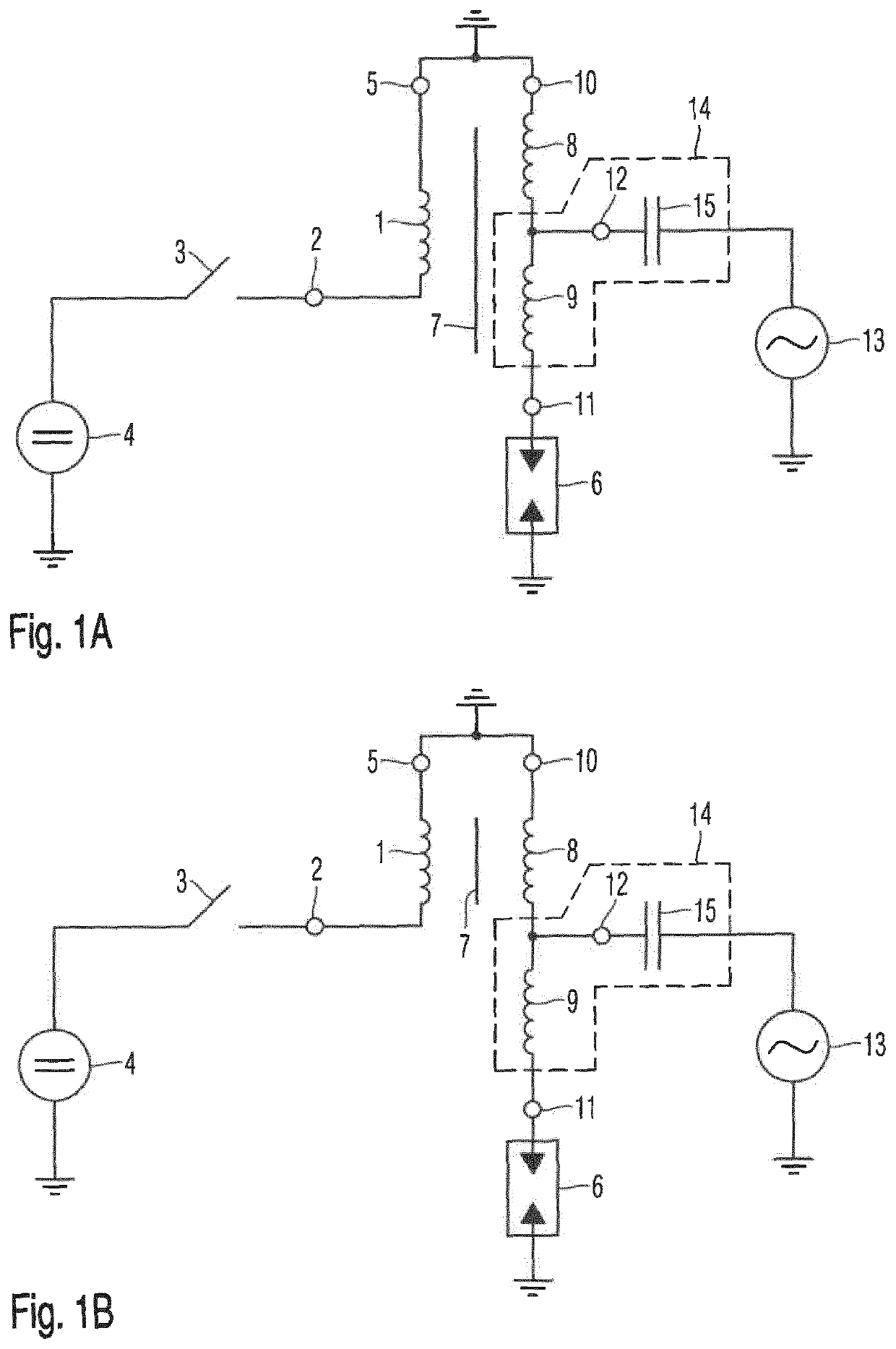

[0090]In the circuit diagram in FIG. 1A, an arrangement for integrating an ignition coil according to the present disclosure with a bandpass filter is illustrated:

[0091]The first coil 1 is connected at one end to the electrode of a DC voltage source 4, preferably a battery, via a DC voltage terminal 2 of the ignition coil, a switch 3. The other electrode of the DC voltage source 3 is connected to a ground potential. The further electrode of the first coil 1 is also connected to a ground potential via a ground terminal 5 of the ignition coil. In the phase before the ignition of the spark plug 6, which is connected to the ignition coil, the switch 3 is closed. A DC current, which is driven by the DC voltage of the DC voltage source 5, flows through the first coil 1 of the ignition coil.

[0092]In order to fire the spark plug 5, the switch 3 is opened, and therefore the flow of current through the first coil 1 is interrupted. This interruption of the flow of current induces a voltage pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com