Secondary battery

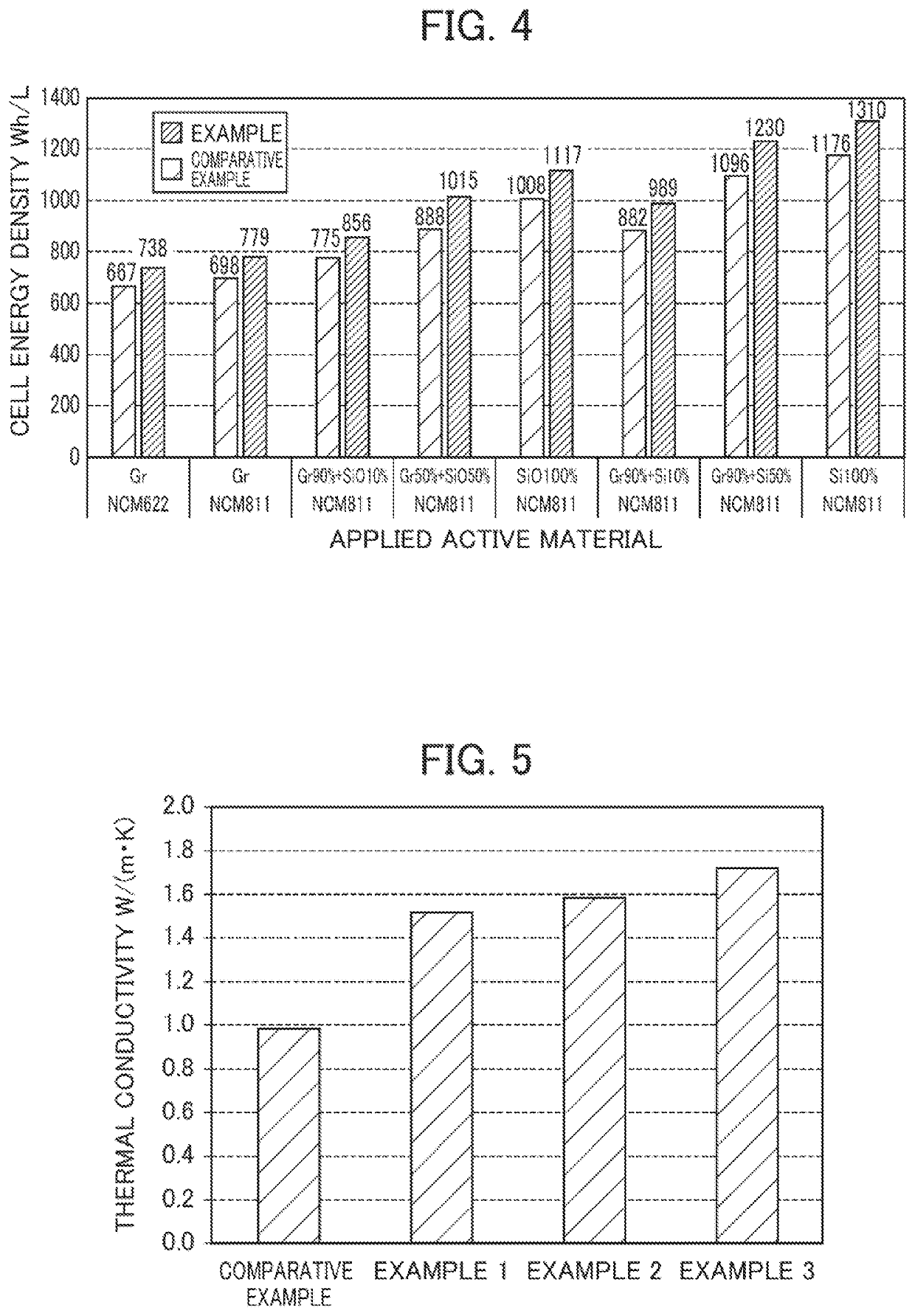

a second battery and battery technology, applied in the field of secondary batteries, can solve the problems of reducing size, energy density, and insufficient effect, and achieve the effects of reducing size and weight, resisting components, and high heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

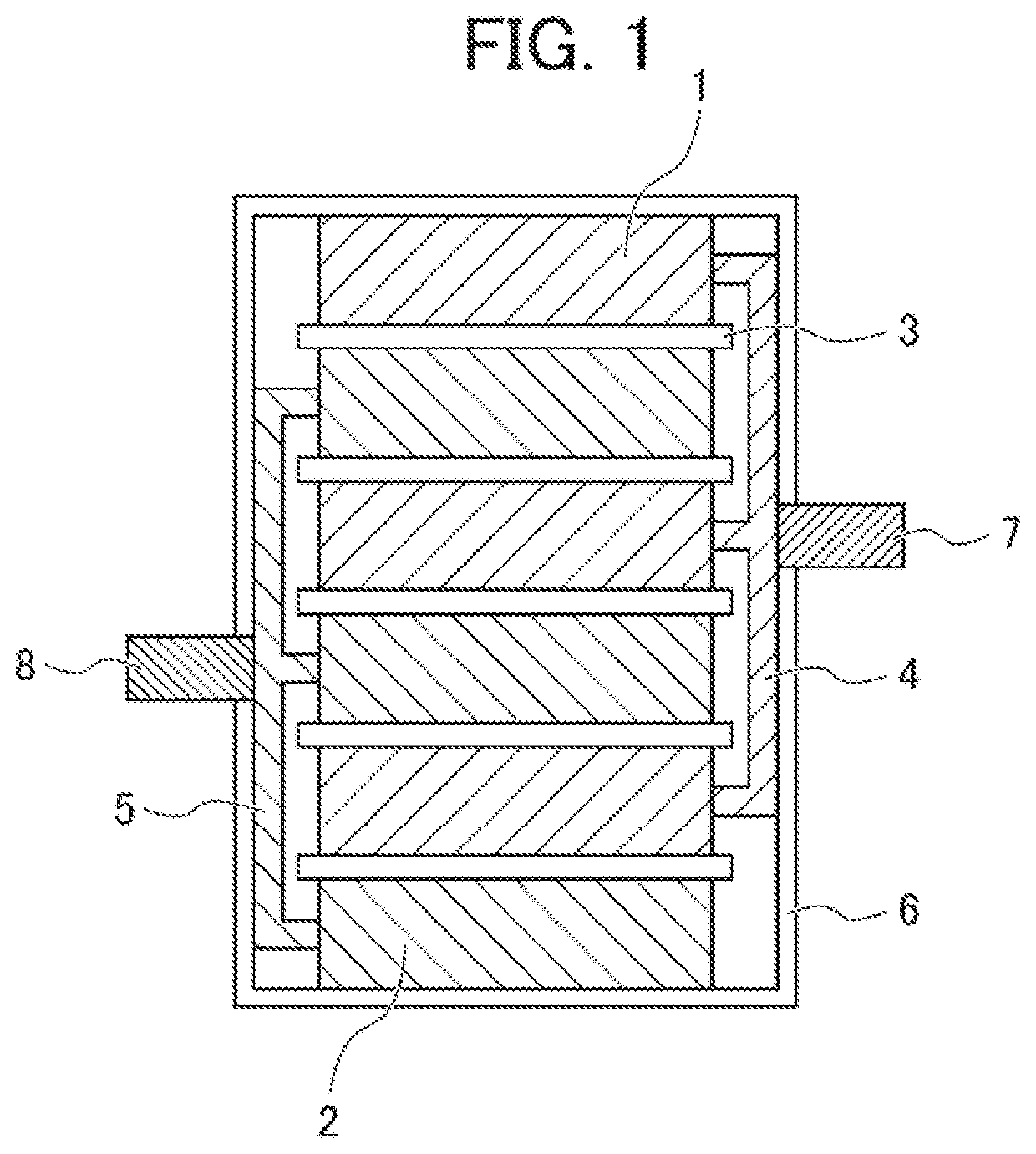

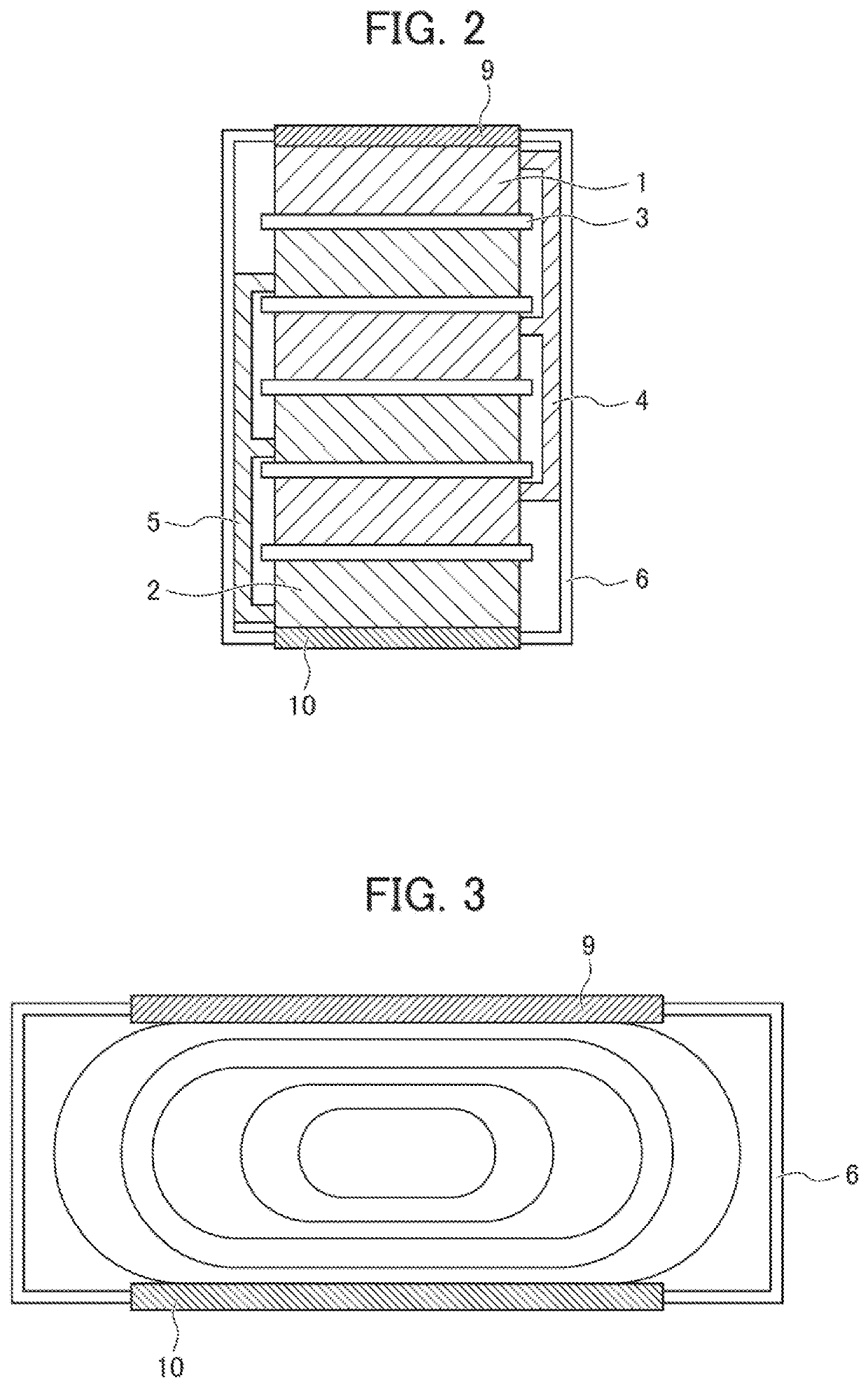

[0029]FIG. 1 shows a cell structure of a battery cell of a typical secondary battery. A reference numeral 1 indicates a positive electrode, a reference numeral 2 indicates a negative electrode, and a reference numeral 3 indicates a separator. The positive electrodes and the negative electrodes are stacked on each other in the order of the positive electrode and the negative electrode from above with each separator being interposed between the positive electrode and the negative electrode. A reference numeral 4 indicates a positive electrode collection member that collects power from each of the stacked positive electrodes, and a reference numeral 5 indicates a negative electrode collection member that collects power from each of the stacked negative electrodes. A reference numeral 6 indicates an exterior body formed of, e.g., a laminated film, and entirely covers the stack of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com