A production process for manufacture of a laminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0311]Various embodiments are described with reference to the Figures. Throughout the Figures and specification, the same reference numerals may be used to designate the same or similar components, and redundant descriptions thereof may be omitted.

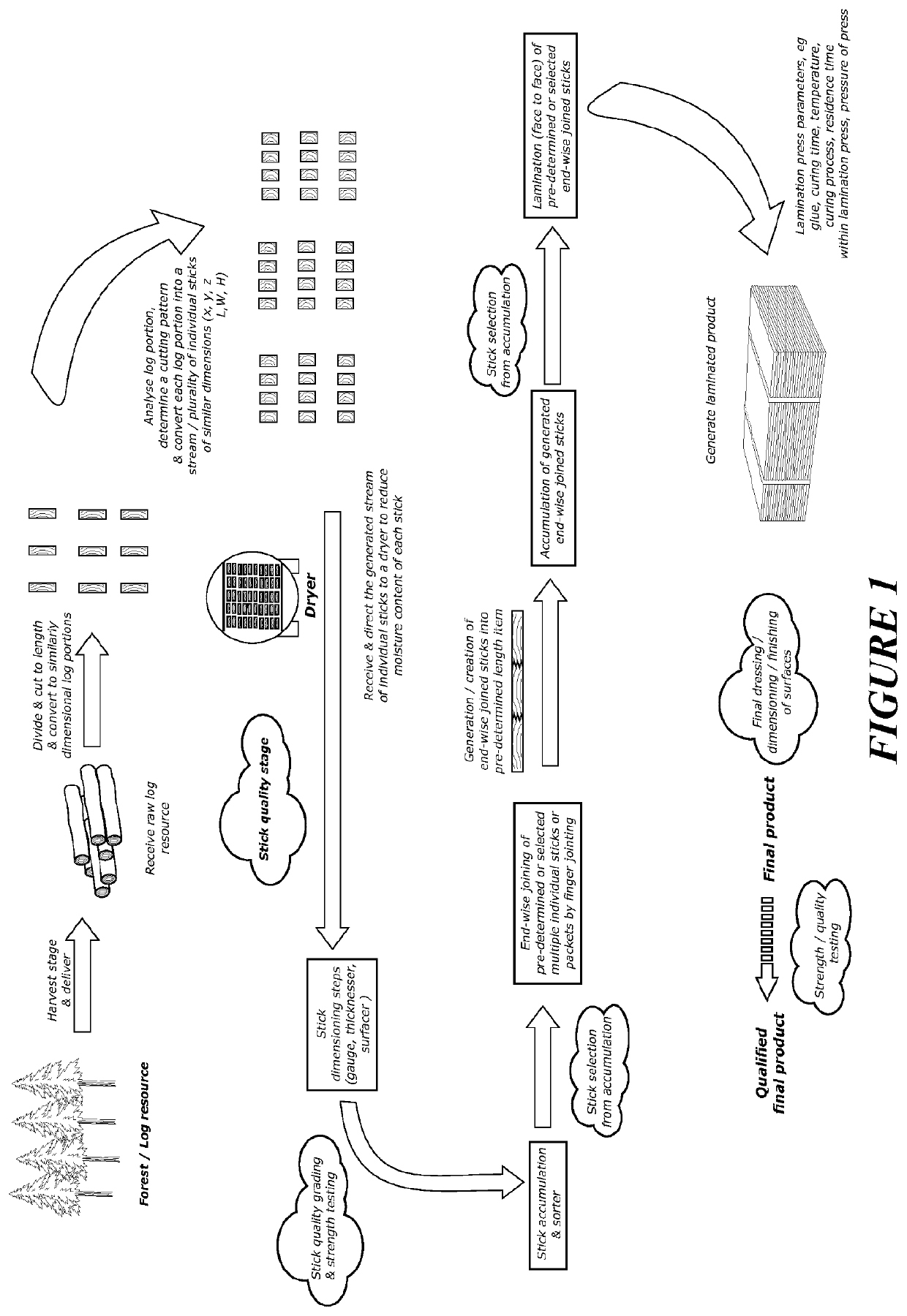

[0312]FIG. 1 shows an exemplary process flow for break-down of a log source through to assembly of a laminate product formed of a laminae of composite sticks.

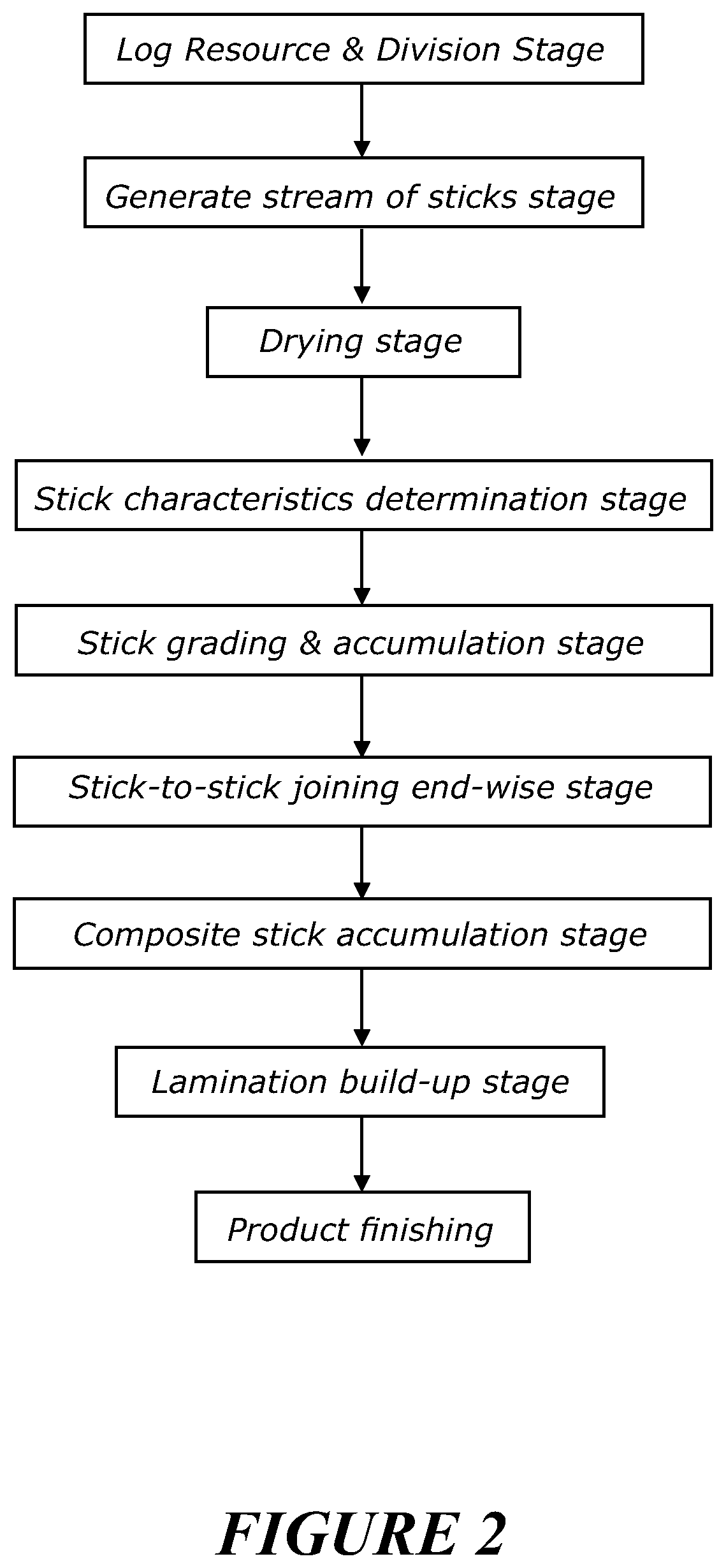

[0313]FIG. 2 illustrates a process flow diagram setting out a sequence of steps in the production of a laminate product. Each of the individual steps may be conducted on their own or in combination with any of the other steps as described herein.

[0314]The provision of a process (and accompanying plant) capable of breaking down or utilising traditionally lower value log material for the manufacture of higher value structural lumber is an area of key interest. Reference to ‘lower value’ being typically or traditionally attributed to one or more of: shape of log (being non-straight), str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com