Method of and apparatus for controlling the operation of a clutch in the power train of a motor vehicle

a technology of motor vehicles and clutches, which is applied in the direction of mechanical equipment, belts/chains/gearings, and control of gears, etc., can solve the problems of preventing the engine from developing an adequate power and the engine from reaching an rpm, and achieve the effect of reliable and economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

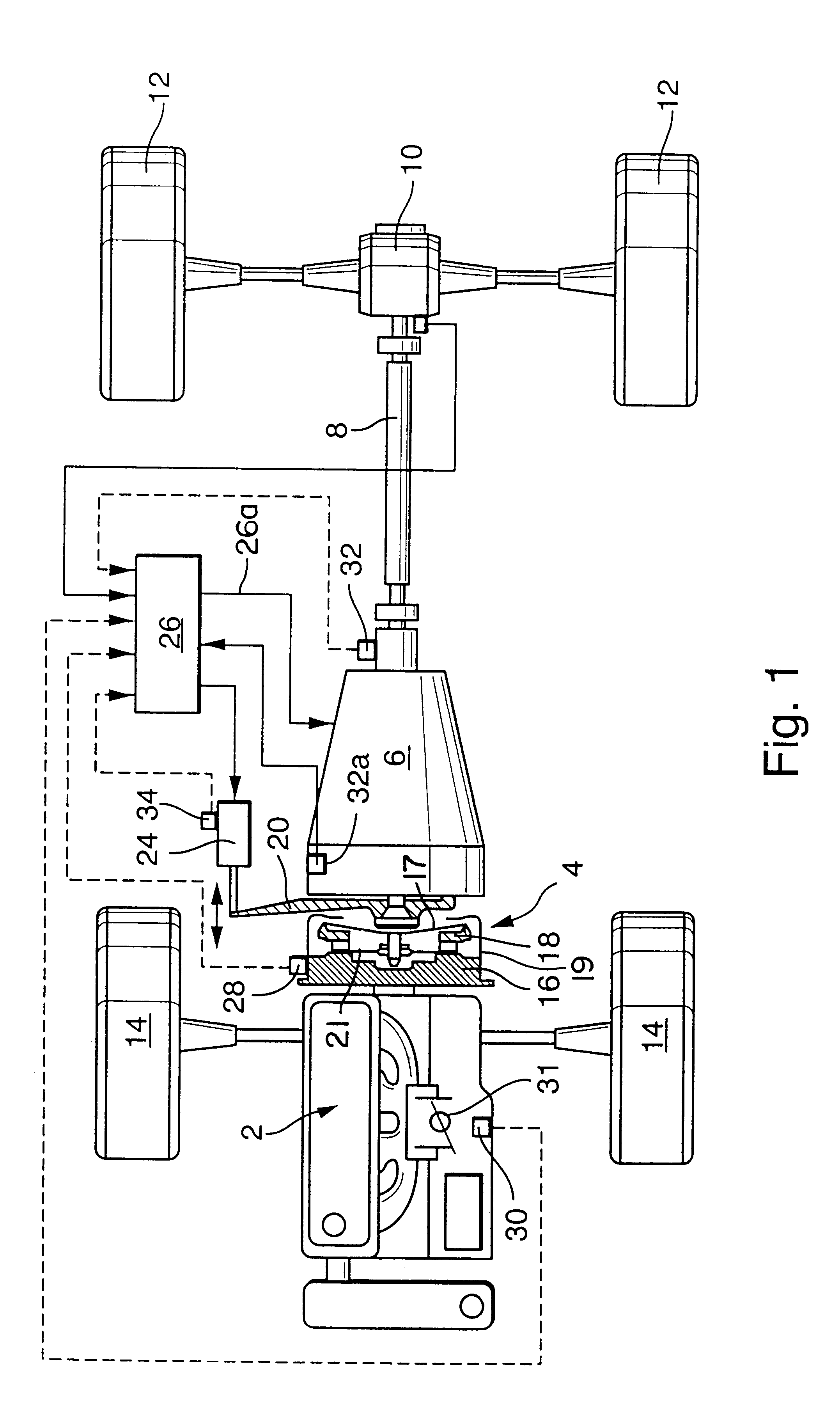

FIG. 1 shows a portion of a motor vehicle having a power train including a prime mover 2 (such as an internal combustion (Otto) engine) with a rotary output element (such as a camshaft or a crankshaft) which drives a flywheel 16 constituting the counterpressure plate of an automated torque transmitting system 4 in the form of a friction clutch further having an axially movable pressure plate 18 biased by a clutch spring 17 which reacts against a clutch housing 19. When the clutch 4 is at least partially engaged, the clutch spring 17 reacts against the housing 19 and causes the pressure plate 18 to urge the friction linings of a rotary clutch disc or clutch plate 21 against the adjacent friction surface of the flywheel 16 so that the clutch disc 21 can rotate the input element (e.g., a shaft) of an automated transmission 6. The output shaft 8 of the transmission 6 drives a differential 10 for the axles of the rear wheels 12 of the motor vehicle. The front wheels 14 of the illustrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com