Gas feeding system for chemical vapor deposition reactor and method of controlling the same

a technology of chemical vapor deposition and gas feeding system, which is applied in the direction of chemically reactive gases, coatings, crystal growth process, etc., can solve the problems of process disadvantages such as the waste of non-use and idling gaseous reactant sources, and the impact of film thickness, film quality, and impurity concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

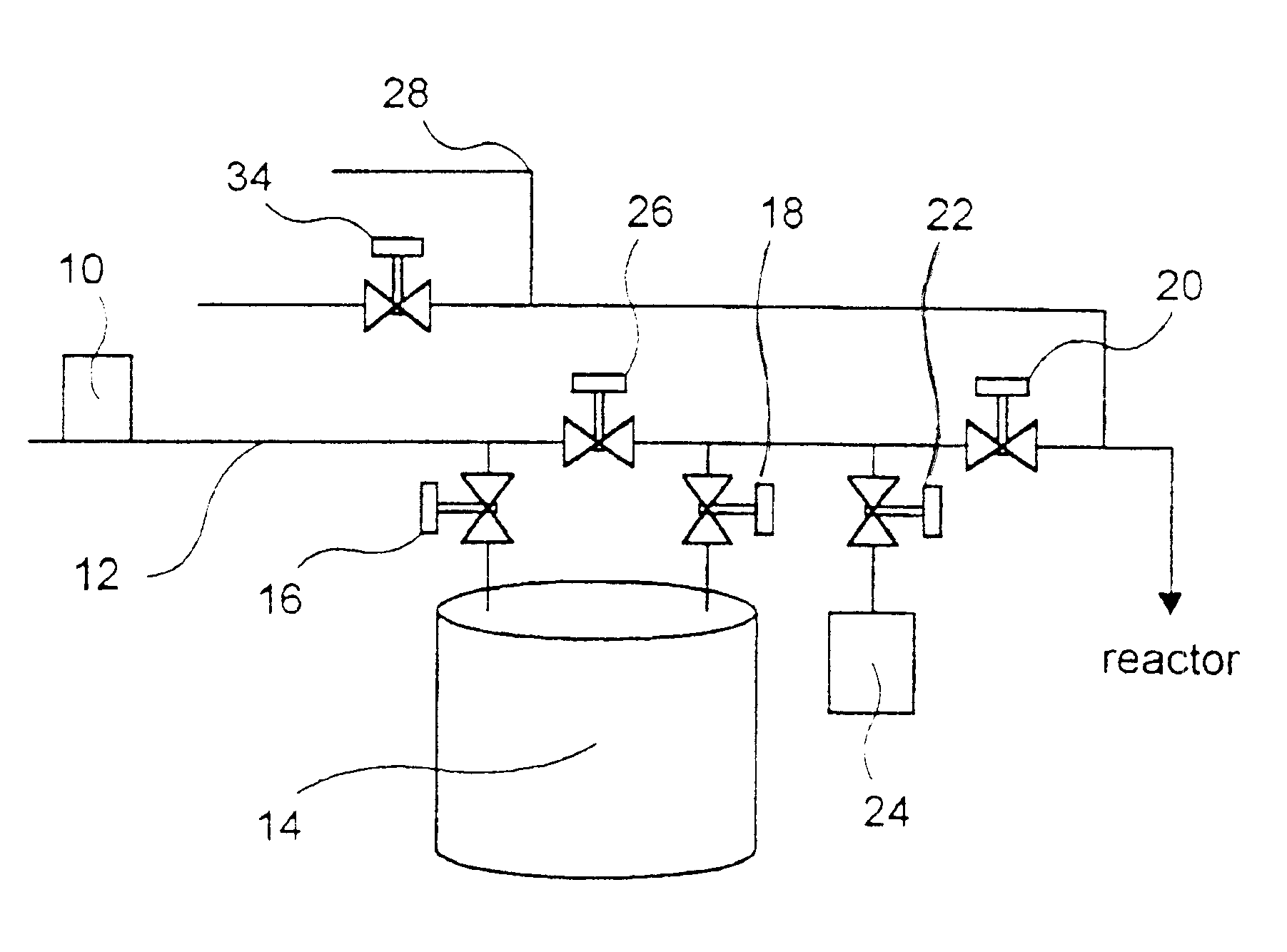

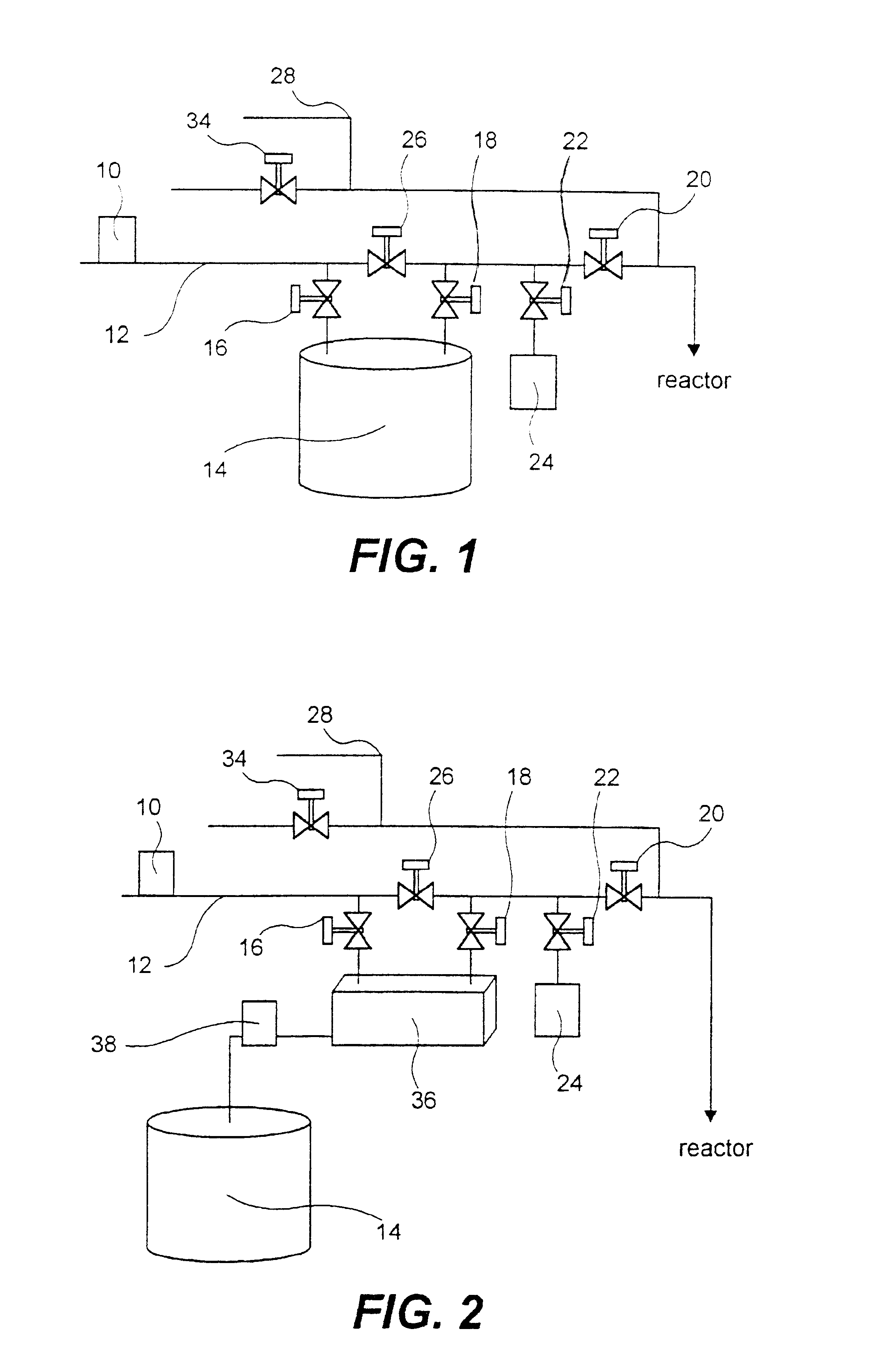

FIG. 2 is a schematic view of a gas feeding system, having a reactant source vaporizer, in accordance with another embodiment of the present invention. Referring to FIG. 2, the difference between the example 1 and the example 2 is that a vaporizer 36 for vaporizing the reactant source is disposed between the reactant source supply tube 12 and the reactant source reservoir 14. Moreover, a minute flow pump 38 is disposed between the reservoir 14 and the vaporizer 36 for the effective control of reactant source supply and its vaporization. The vaporizer 36 vaporizes the reactant source in liquid phase contained in the reservoir 14 beforehand to supply the reactant source into the reactor. The operation of other parts of the gas feeding system is the same as that of the example 1.

example 3

FIG. 3 is a schematic view of a gas feeding system with a plurality of reactant source supply apparatuses connected to one reactor, in accordance with another embodiment of the present invention. Referring to FIG. 3, two reactant source supply apparatuses B and C, each being the same as described in the example 1, are connected to one reactor. Additionally, a reactive gas supply apparatus A is connected to the reactor via a reactive gas supply tube 40. The flow of gas A to the reactor is regulated by a supply valve 20 disposed on the reactive gas supply tube 40. An evacuation valve for evacuating the gas A is indicated with reference numeral 22.

As is the same as the examples 1 and 2, each supply apparatus comprises a first purge gas supply unit 28 and a mass flow controller (not shown) for the purge gas to prevent the backward flow of other reactant sources from the reactor upon deposition reaction. Additionally, each supply apparatus comprises a second purge gas supply unit for pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow rate | aaaaa | aaaaa |

| mass flow | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com