Spring seat for a railway truck sideframe and method of making the same

a technology of railway truck and sideframe, which is applied in the direction of manufacturing tools, foundry patterns, foundry moulding apparatus, etc., can solve the problems of voids in the sand core, defects in the cast metal component, and problems during the manufacture of sand cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

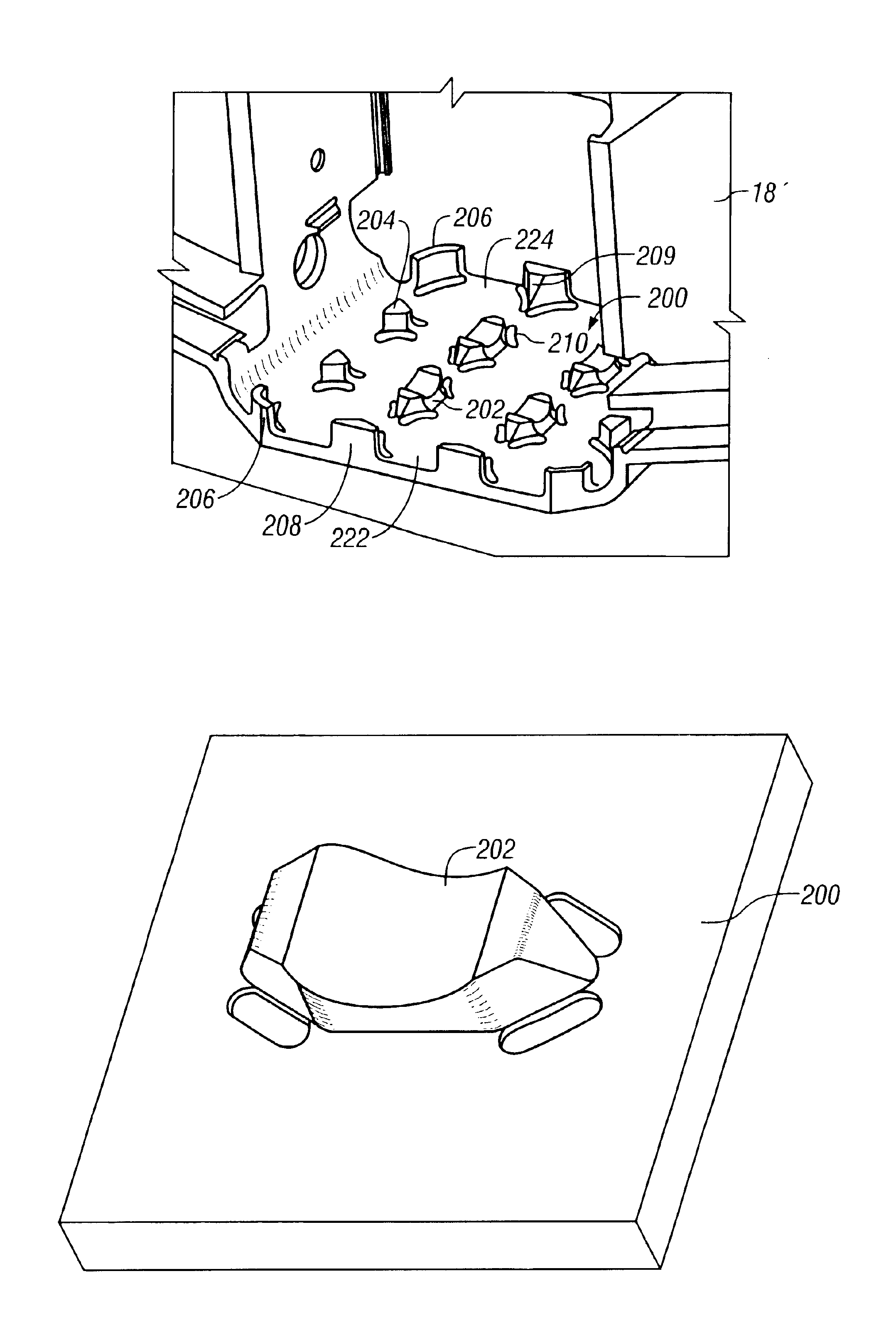

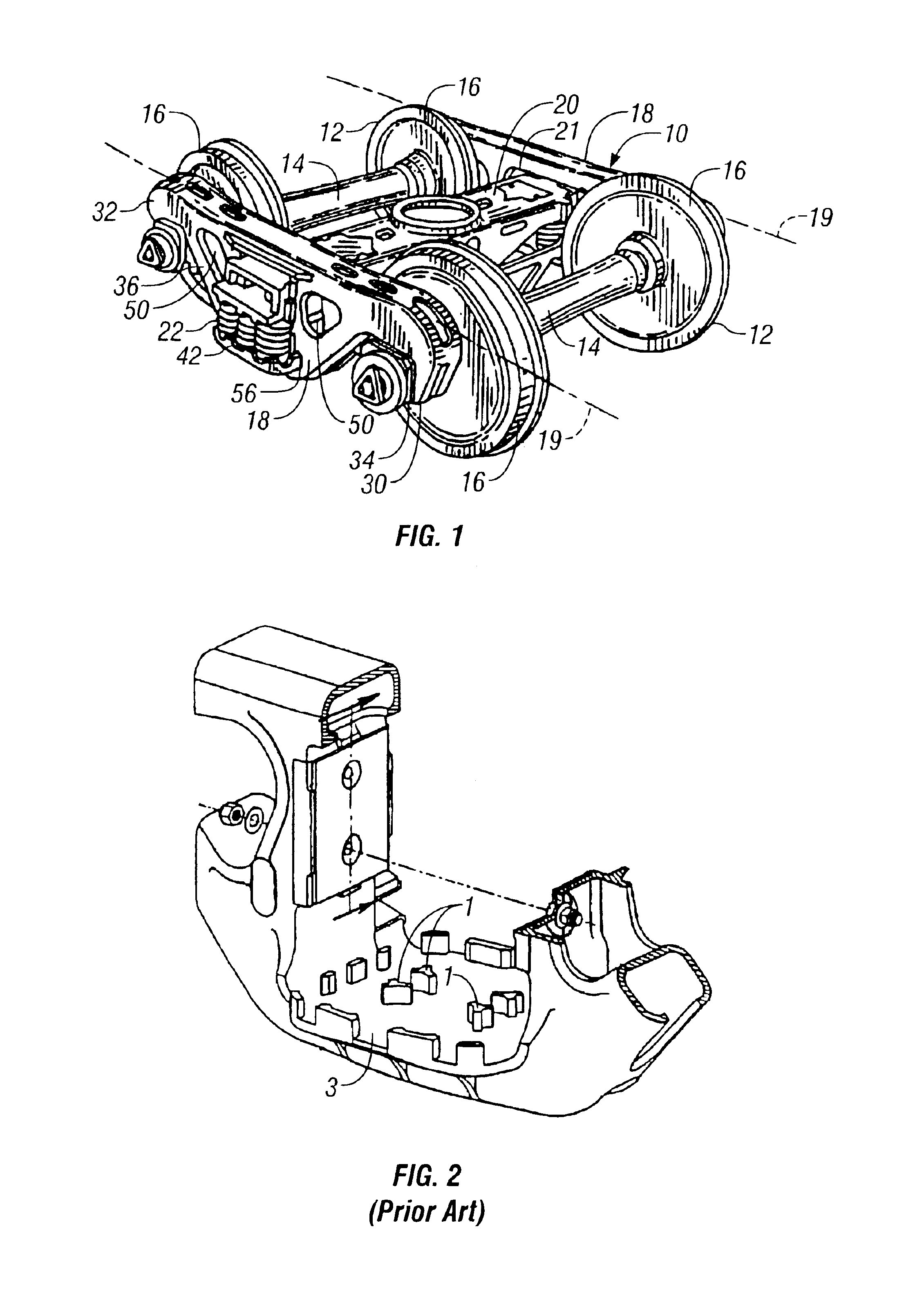

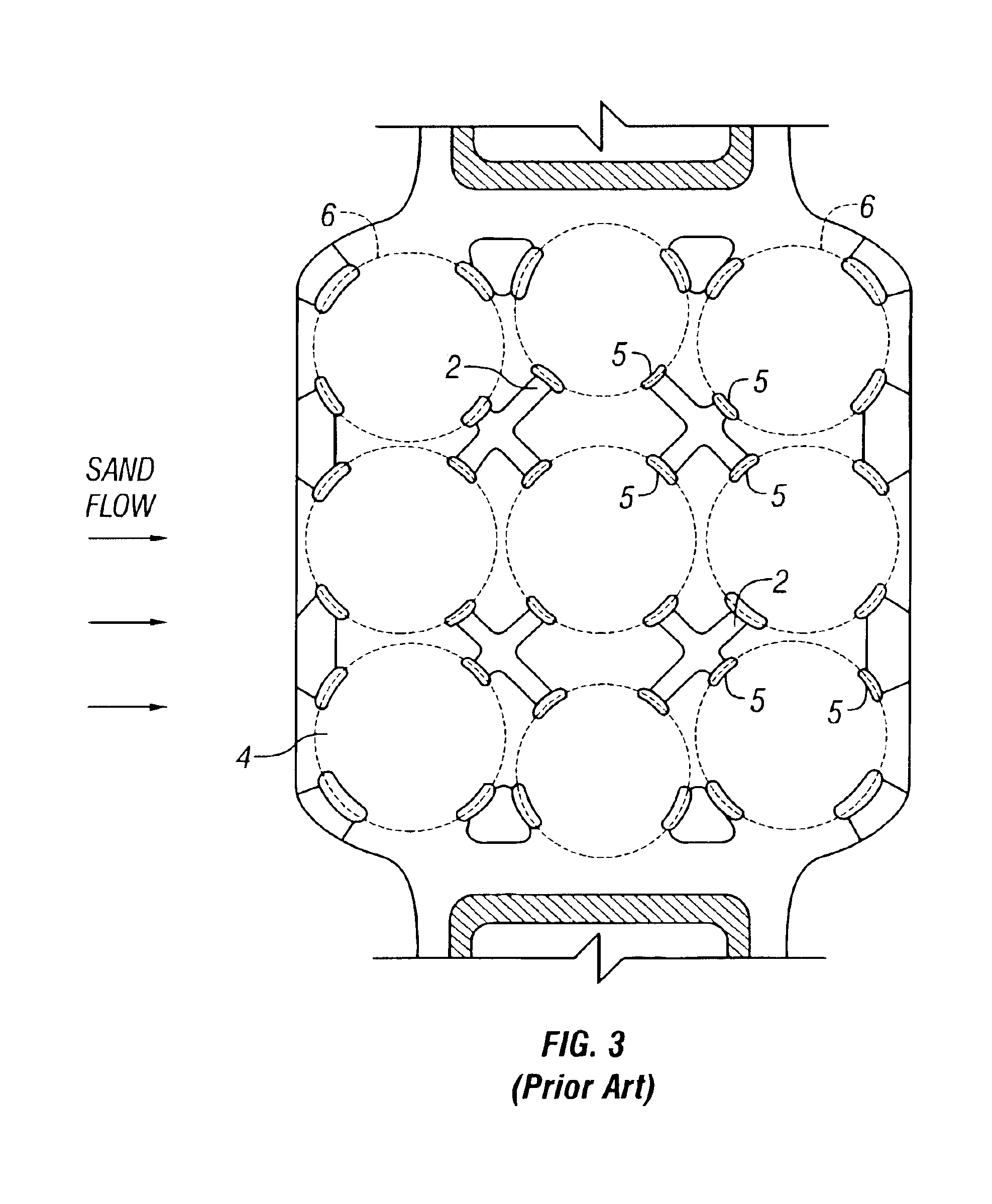

A railway truck 10 that may utilize a cast spring seat according to certain aspects of an embodiment of the present invention is illustrated in FIG. 1. Except as explained below, the railway truck 10 may be constructed generally in accordance with the rail trucks described in U.S. Pat. No. 5,481,986, issued Jan. 9, 1996 to Spencer et al. and entitled "Lightweight Truck Side Frame" (the "'986 Patent) and U.S. Pat. No. 5,752,564, issued May 19, 1998 to Callahan et al. and entitled "Railway Truck Castings and Method and Cores for Making Castings" (the "'564 Patent"). The disclosures of the '986 patent and the '564 patent are hereby incorporated by reference herein in their entirety.

As is shown in FIG. 1, a typical railway truck 10 includes a pair of wheelsets 12. Each wheel set 12 has an axle 14 with wheels 16 at the ends of each axle 14. The two wheelsets 12 support a pair of spaced, parallel sideframes 18. The two sideframes 18 have longitudinal centerlines 19 and are spanned by a bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angles | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| obtuse angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com