Automotive catalyst oxygen storage capacity diagnostic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The following description of the preferred embodiment is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses. For purposes of clarity, the same reference numbers will be used in the drawings to identify similar elements.

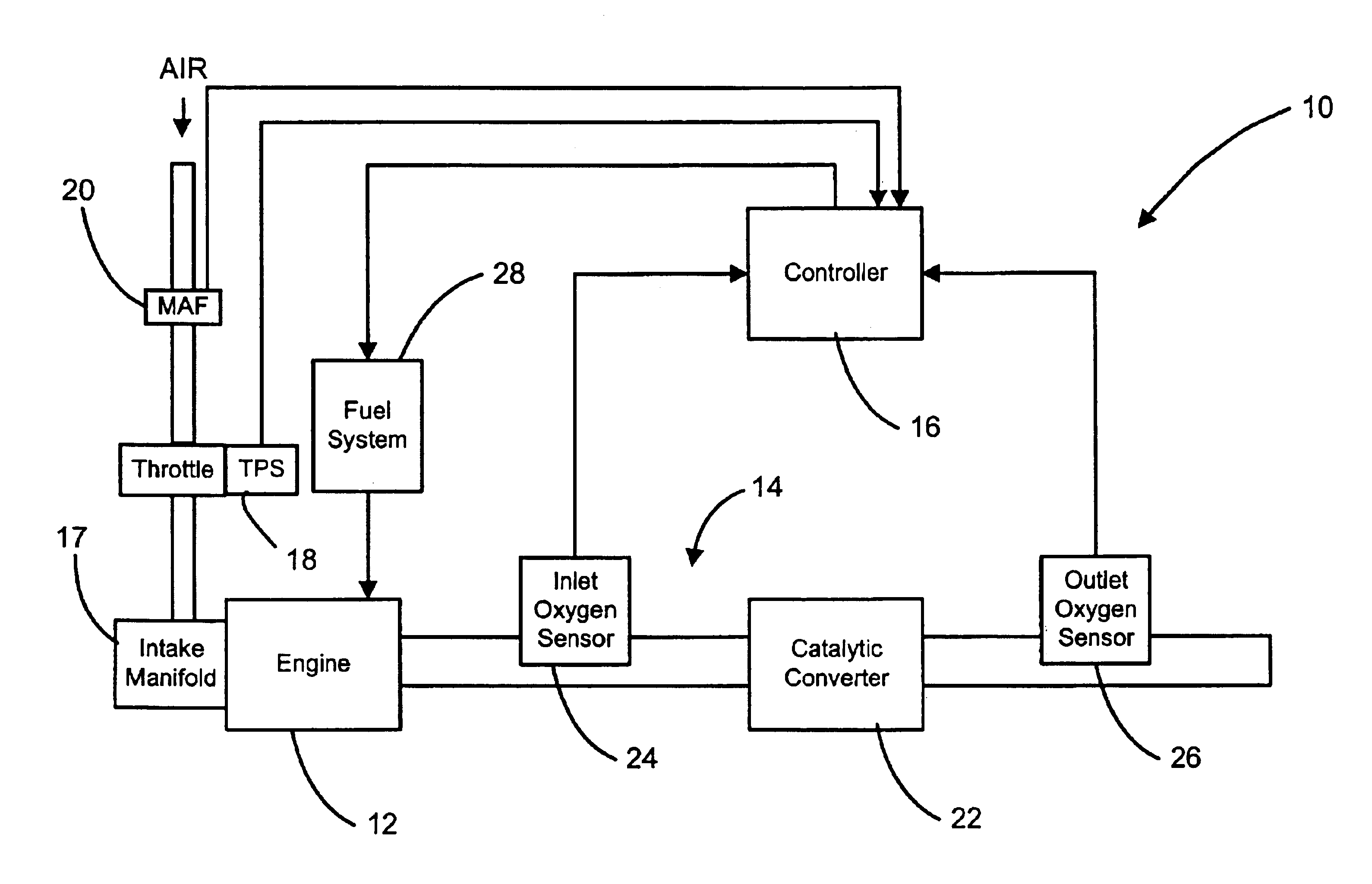

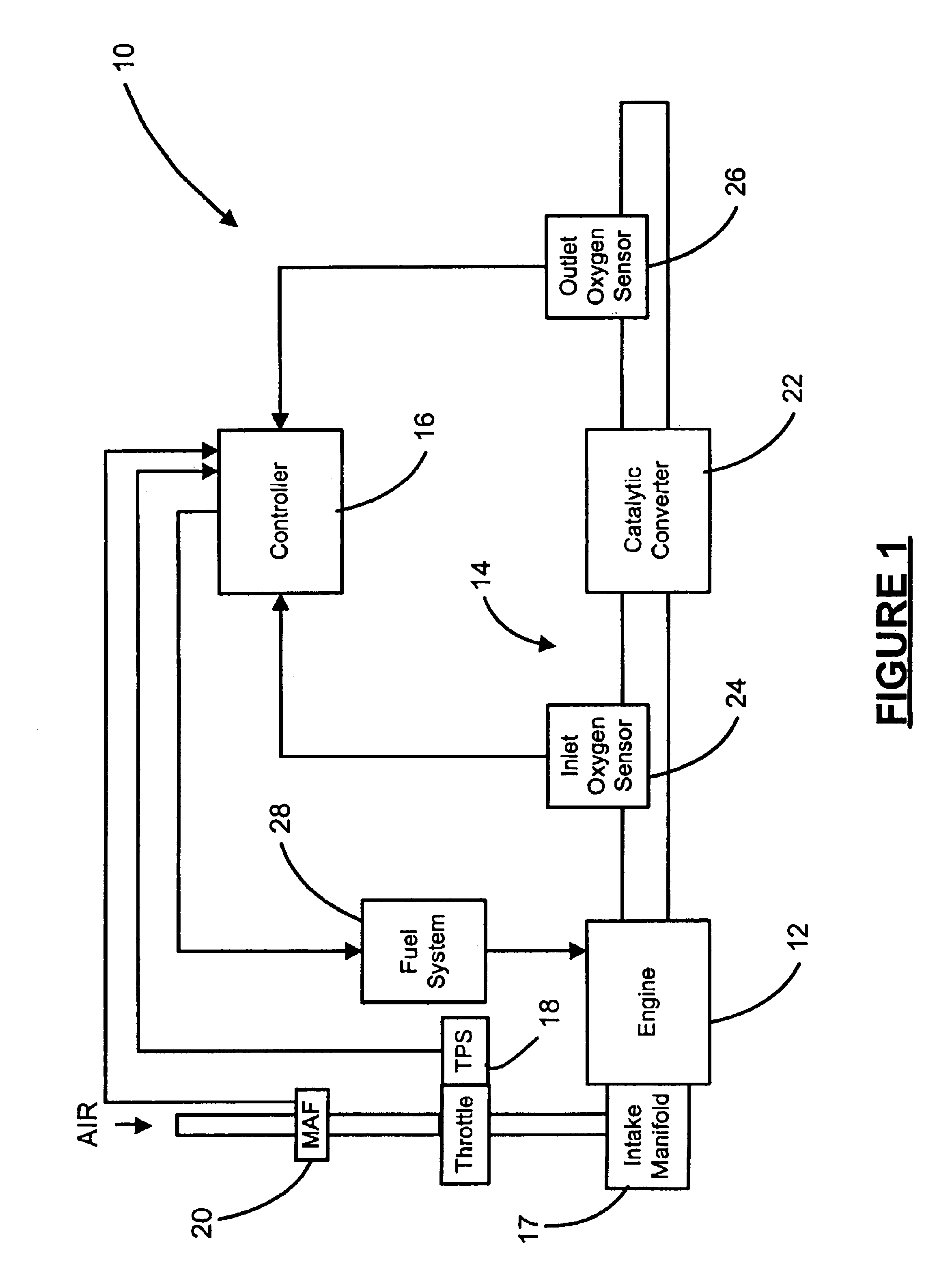

Referring now to FIG. 1, a vehicle 10 includes an engine 12, an exhaust 14 and a controller 16. The engine 12 includes an intake manifold 17, a throttle position sensor (TPS) 18 and a mass air flow (MAF) sensor 20. The throttle position sensor 18 and the MAF sensor 20 communicate with the controller 16. The exhaust 14 includes a catalytic converter 22, a pre-catalyst or inlet oxygen sensor 24, and a post-catalyst or outlet oxygen sensor 26. The inlet and outlet oxygen sensors 24, 26 communicate with the controller 16 to provide inlet and outlet F / A ratio signals, respectfully. The controller 16 communicates with a fuel system 28 to regulate fuel flow to the engine 12. In this manner, the controller 16 regulates the F / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com