Microscope, detector, and method for microscopy

a microscope and detector technology, applied in the field of microscopes, can solve the problems of living specimens, much greater specimen damage, ultraviolet light illuminating, etc., and achieve the effect of simple and economical manufacture, uncomplicated and reliable determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

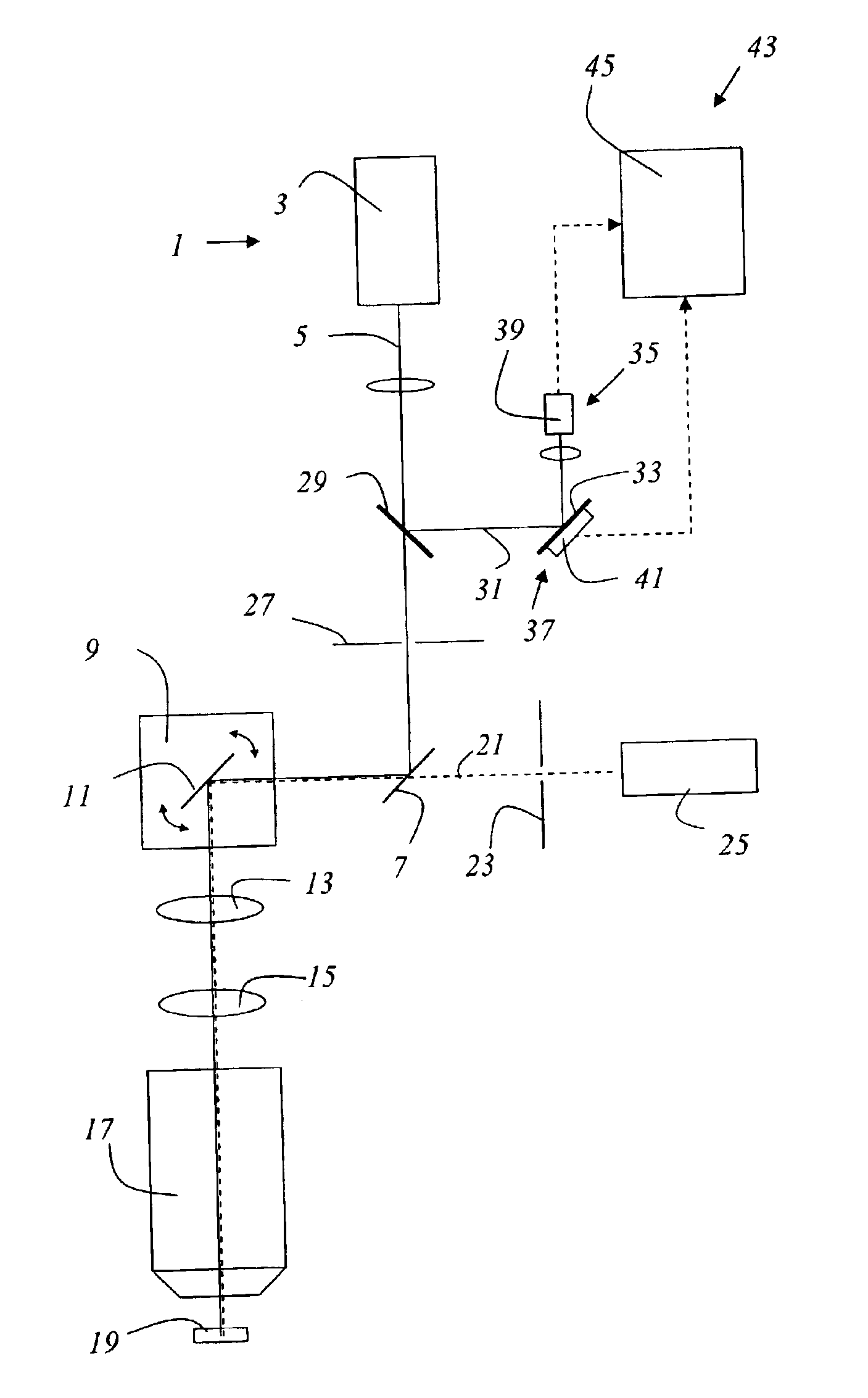

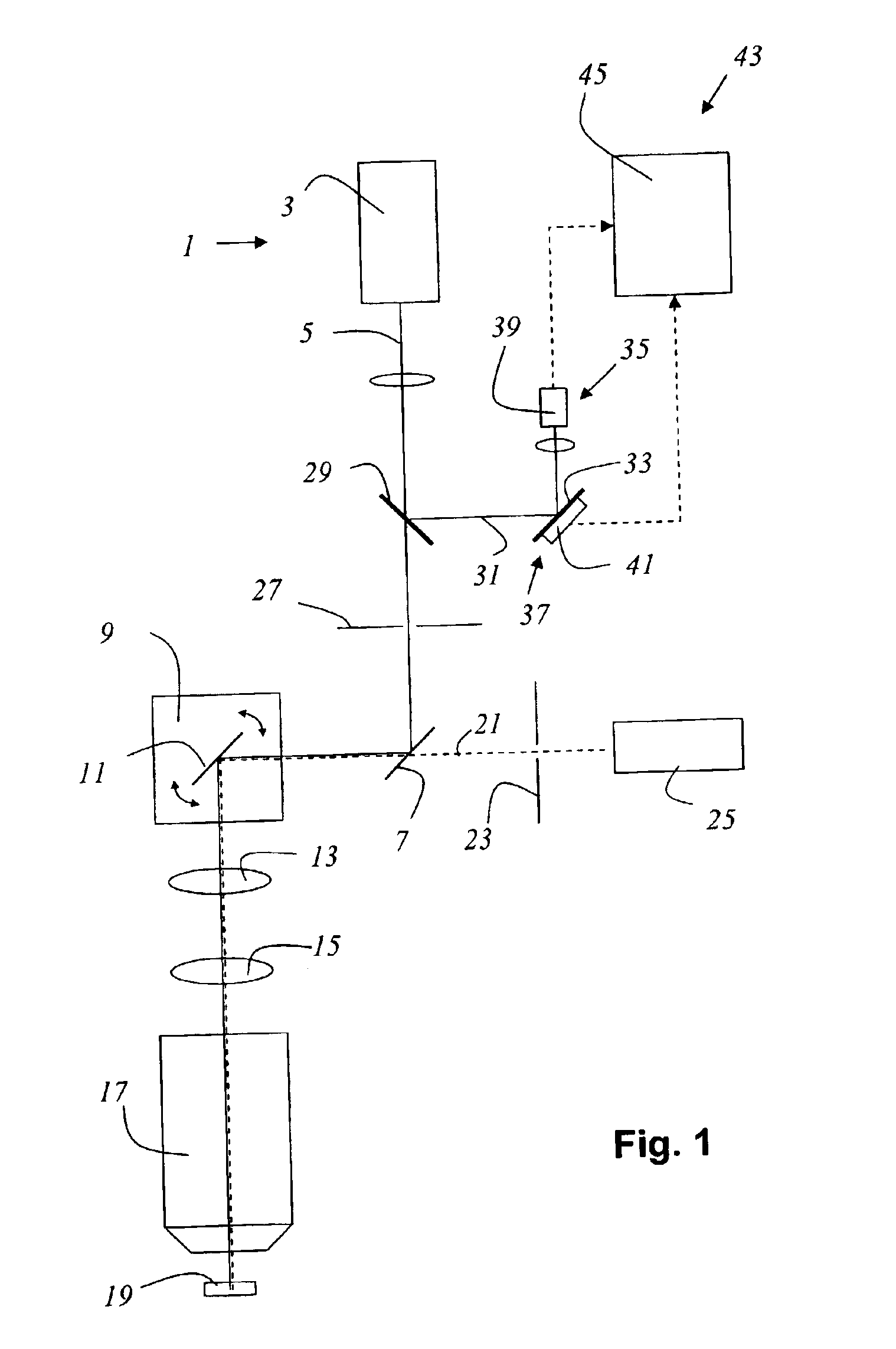

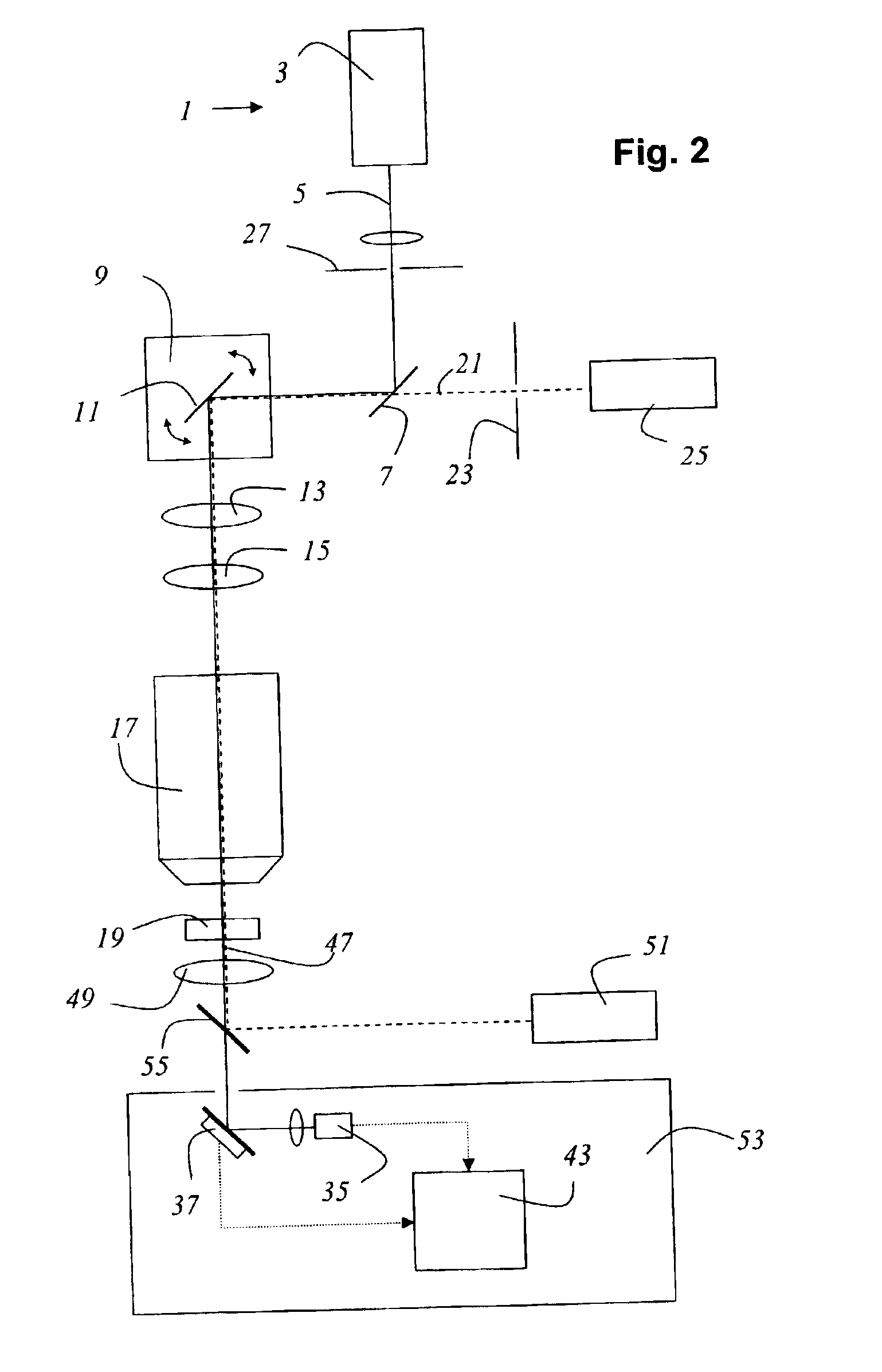

[0041]FIG. 1 schematically shows a microscope according to the present invention that is embodied as a confocal scanning microscope. The microscope contains a light source 1 that is embodied as a mode-coupled titanium:sapphire laser 3. Light 5 emitted from titanium:sapphire laser 3, which has a wavelength of 780 nm, contains light pulses with a repetition rate of 80 MHz. The duration of the light pulses is approx. 1 ps. After passing through an excitation pinhole 27, light 5 is reflected by a main beam splitter 7 of a beam deflection device 9 that contains a gimbal-mounted mirror 11, and is guided by beam deflection device 9, through scanning optical system 13, tube optical system 15, and objective 17, over or through specimen 19. Detected light 21 proceeding from specimen 19 travels along the same light path through beam deflection device 9 back to main beam splitter 7, passes through the latter, and after passing through detection pinhole 23 strikes photomultiplier 25. In the draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com