Multi-axis solid state accelerometer

a solid-state accelerometer, multi-axis technology, applied in the direction of speed/acceleration/shock measurement, measurement devices, instruments, etc., can solve the problem of limiting the sensitivity of the accelerometer, and achieve the effect of reducing manufacturing costs, increasing yields, and easy manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

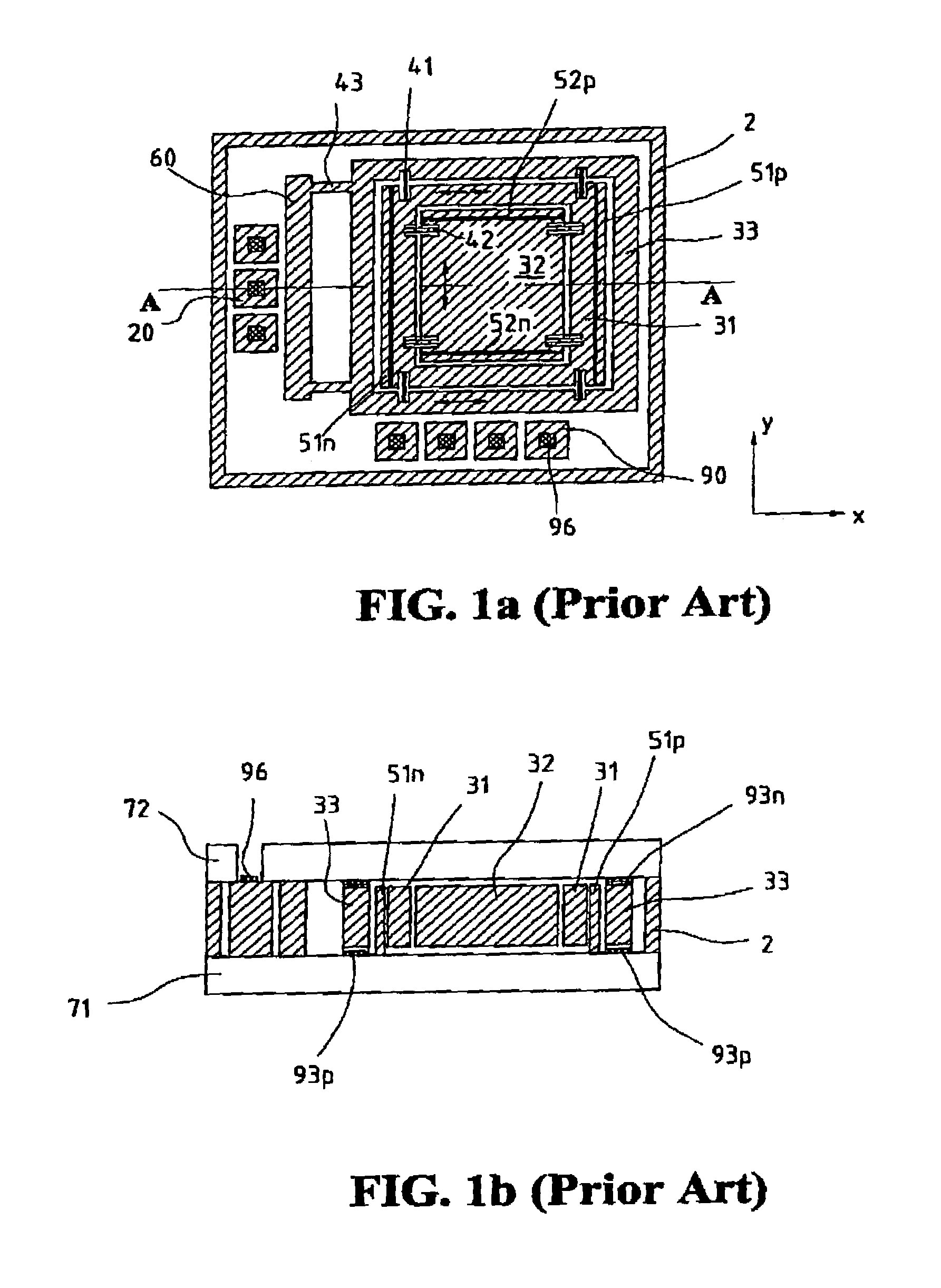

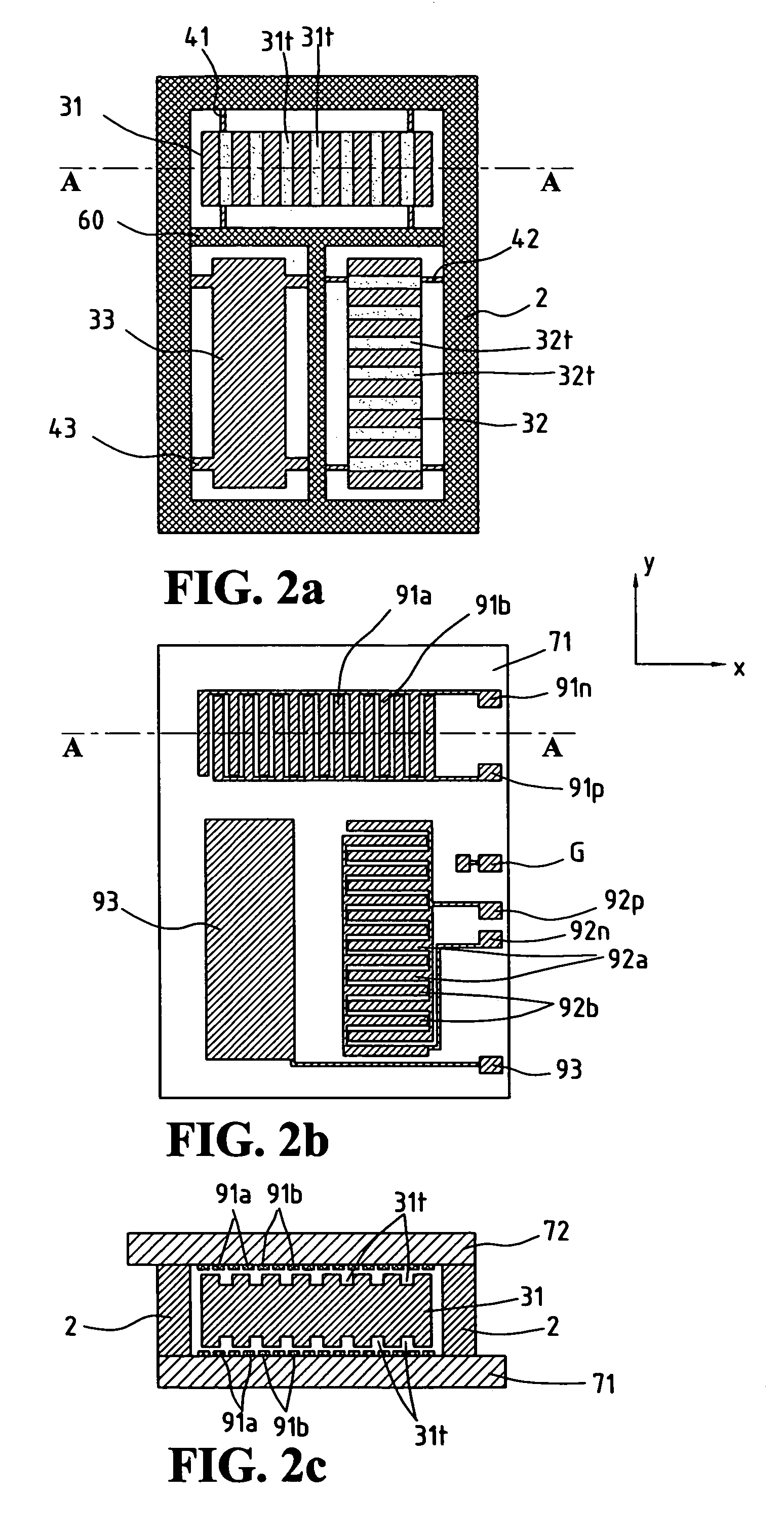

[0017]FIG. 2 shows the three-axis accelerometer in accordance with the present invention wherein FIG. 2a shows a top view of the main structure and includes three proof masses 31, 32, 33 made of electricity conductive material. The three proof masses 31, 32, 33 are connected to a frame 2 or fixing anchors 60 by sensing beams 41, 42, 43. The frame 2 or the anchors 60 are fixed to boards 71, 72. The sensing beams 41, 42, 43 make the proof masses 31, 32, 33 movable only along a first axis, a second axis parallel the boards and z-axis which is perpendicular to the boards. The proof masses 31, 32 each have grooves 31t and 32t that are perpendicular to the first axis and the second axis.

[0018]As shown in FIG. 2b, two sets of interposed stripe electrodes 91a and 91b parallel to the grooves 31t are located corresponding to the grooves 31t on the board 71, 72 and electrically connected to bond pads 91p and 91n, respectively, so as to form a first axis detection capacitors c91p and c91n with ...

second embodiment

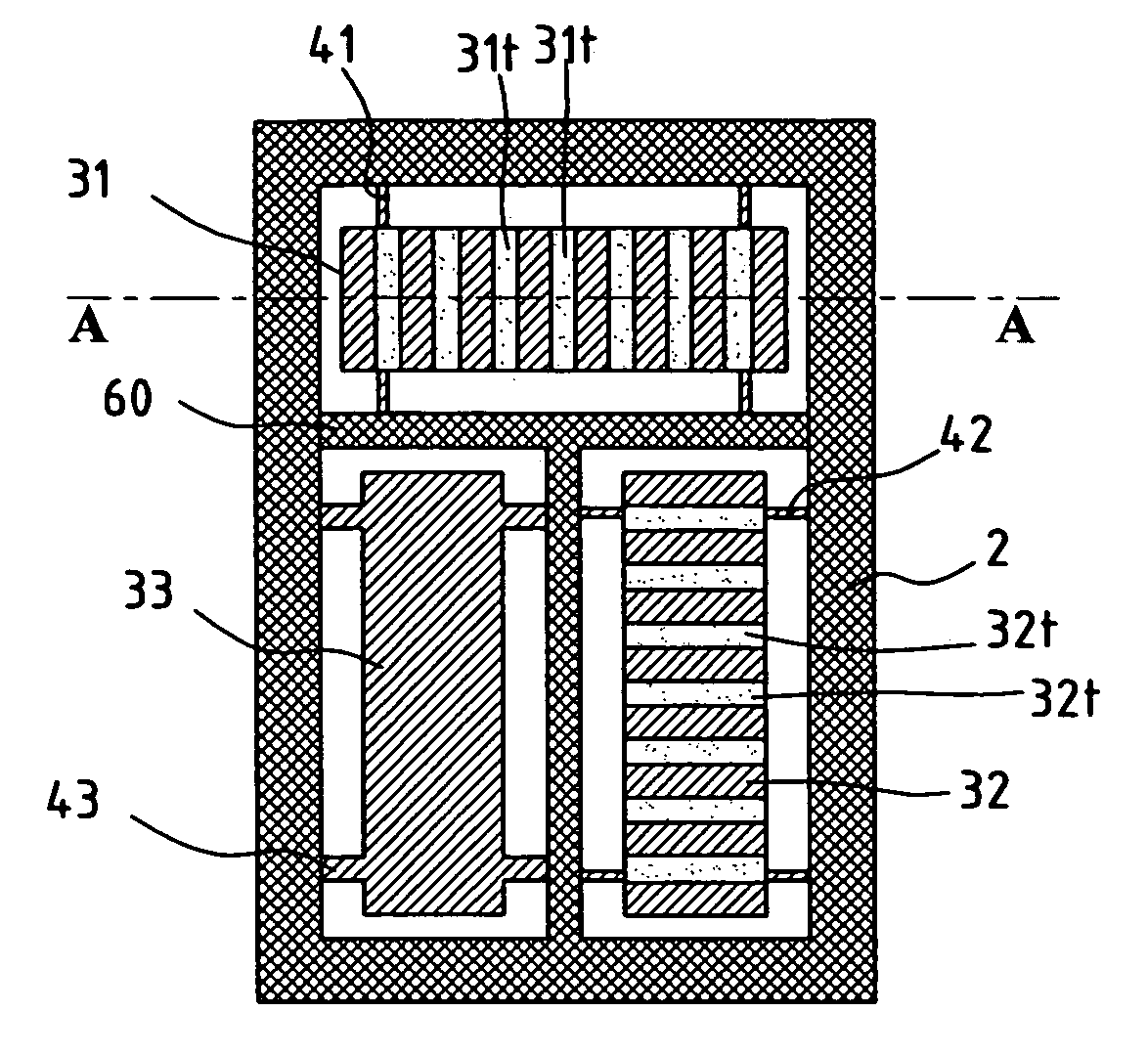

[0022]FIG. 3 shows the three-axis accelerometer. FIG. 3a shows a top view of the main structure made of electricity conductive material and includes three proof masses 31, 32, 33. The two proof masses 31, 32 are connected with each other and located around the proof mass 33 so as to form a proof mass 312. The proof mass 33 is connected to the proof mass 312 by flexible sensing beams 43, and the proof mass 312 is connected to the sensing beam 42 by sensing beams 41. Two ends of the sensing beam 42 are connected to a frame 2 or anchors 60. The frame 2 or the anchors 60 are fixed to boards 71 and 72. The sensing beam 43 makes the proof mass 33 movable only along the z-axis perpendicular to the surface of the boards. The sensing beams 41, 42 make the proof mass 312 movable along the first axis and the second axis parallel to the boards. The proof masses 31, 32 include elongate grooves 31t and 32t perpendicular to the first axis and the second axis.

[0023]As shown in FIG. 3b, two sets of ...

third embodiment

[0030]The main structure of the three-axis accelerometer is shown in FIG. 4, and includes a proof mass 3 that is connected to the sensing beam 42 by flexible sensing beams 41. The other end of the sensing beam 42 is connected to the frame 2 or the anchor 60. The frame 2 or the anchors 60 are fixed to the boards 71, 72. The sensing beams 41 and 42 form an L-shaped sensing beam so as to allow the proof mass 3 to be movable along the first axis, the second axis and movable along the z-axis. The proof mass 3 includes a plurality of grooves 31t, 32t that are perpendicular to the first axis and the second axis, respectively, and an area that has no groove defined therein.

[0031]The electrodes on the boards 71 and 72 are similar to those described in the second embodiment, as shown in FIG. 3b. The principle of acceleration detection on each axis is the same as described above. The acceleration along the first axis does not affect the capacitors c92p, c92n on the second axis and the capacito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com