Hydraulic vehicle lift

a technology for lifting vehicles and lifts, applied in the direction of lifting devices, lifting equipment safety devices, transportation and packaging, etc., can solve the problems of limiting the access to moving parts during operation, reducing etc., to reduce the likelihood of the operator being injured, reduce the wear and tear of the lift parts, and improve the safety of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

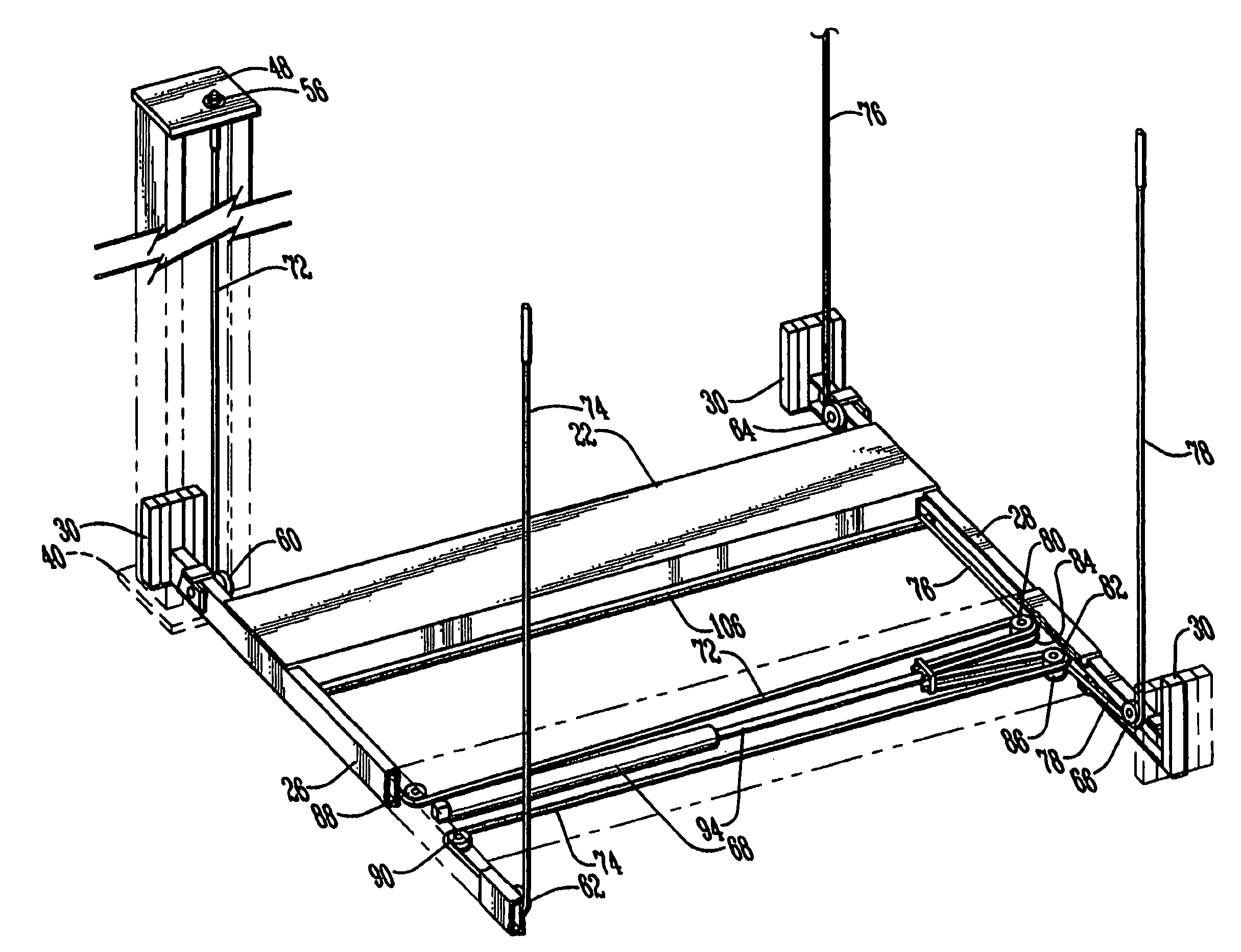

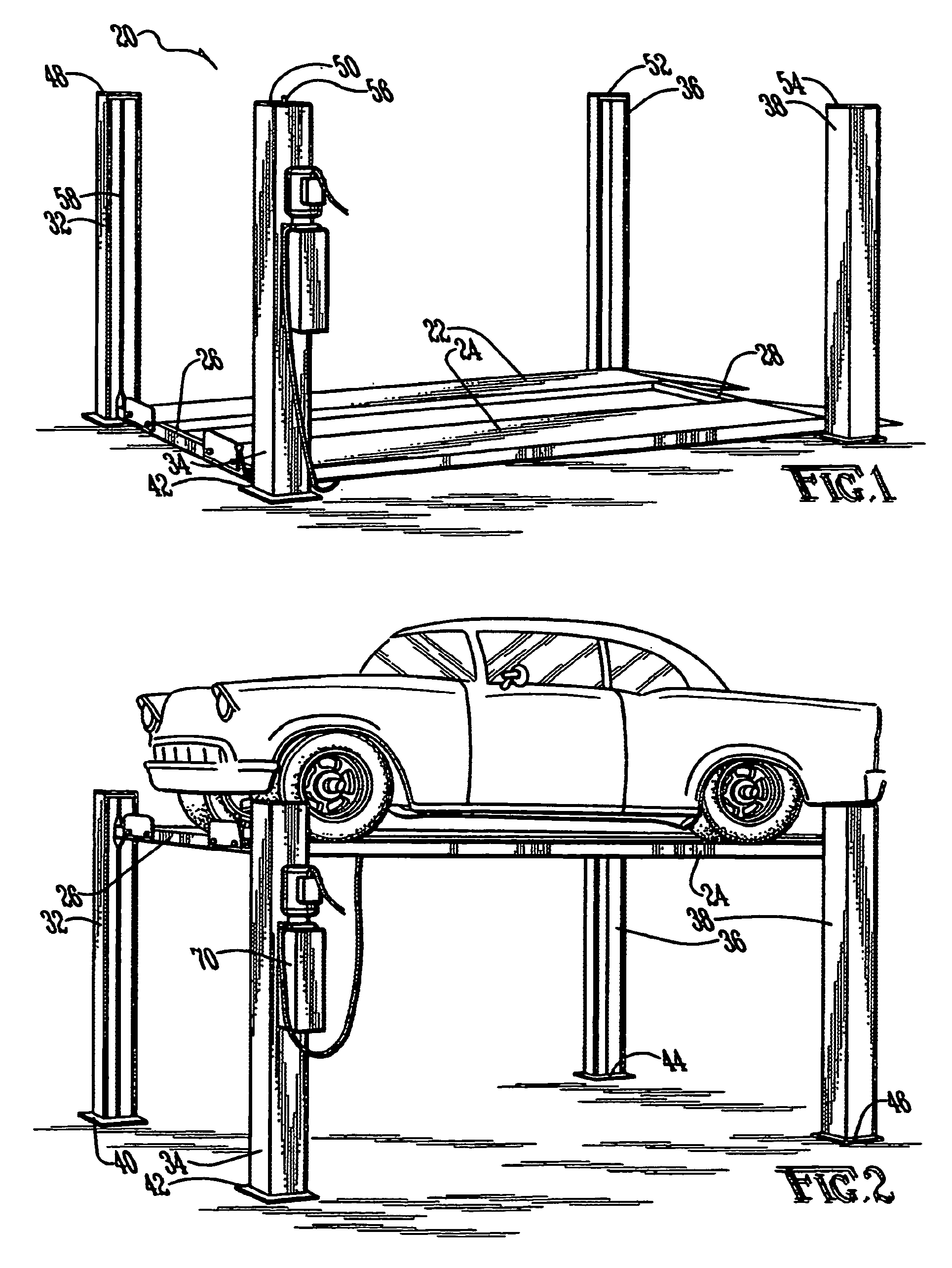

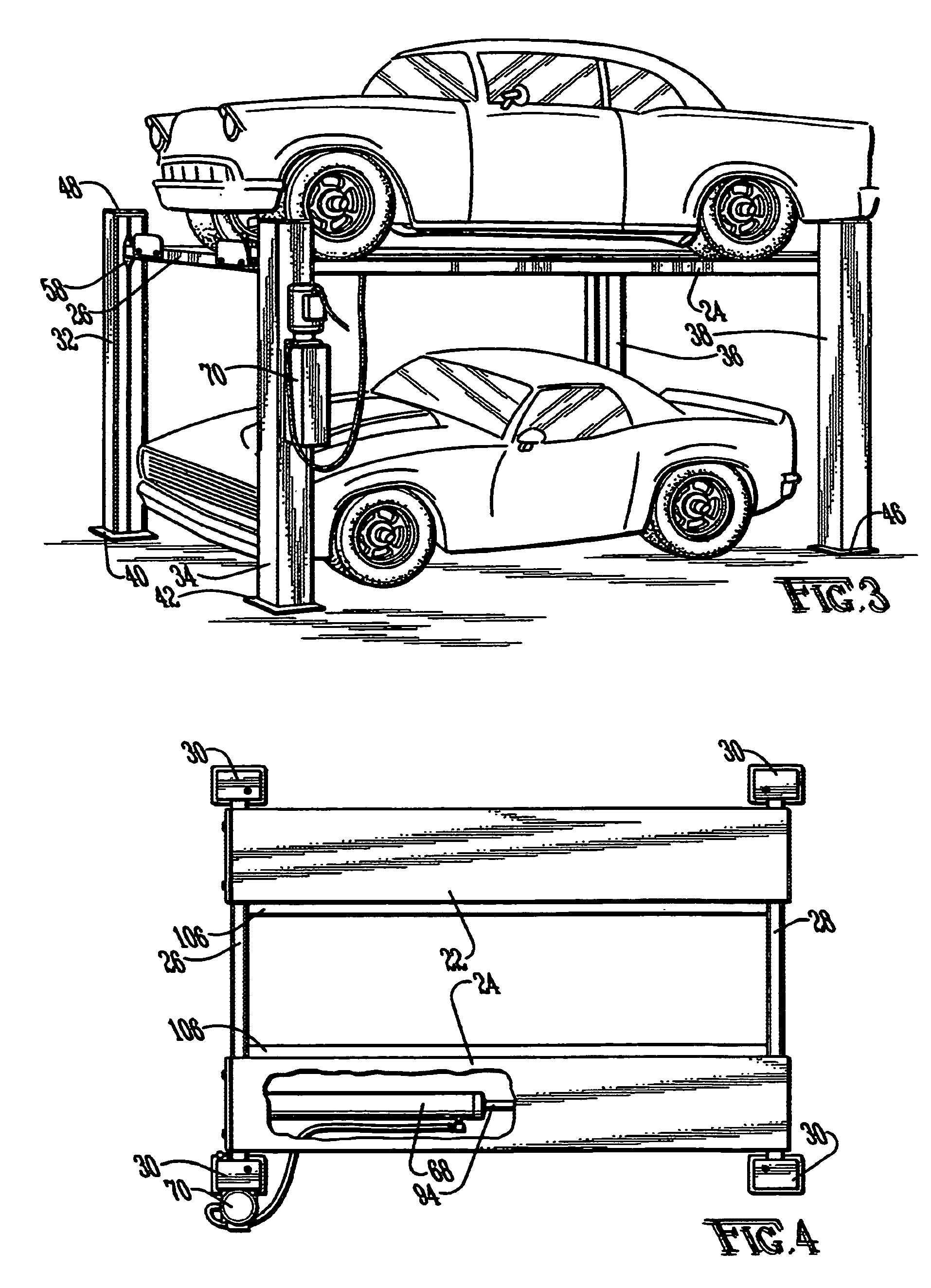

[0031]The present invention relates to a hydraulically operated vertical vehicle lift which allows for a person to work under the vehicle or for storing one vehicle over a second vehicle. The vehicle lift utilizes four large U-shaped columns positioned at each corner of the lift for stability and safety. A vehicle is elevated by a series of cables traversing through the U-shaped columns and around pulleys attached to cross members supporting the vehicle ramps. A hydraulic cylinder provides the lifting force. The orientation of the cables and pulleys direct the force, generated while elevating and suspending a vehicle, in a downward direction, as opposed to an angular direction, from the internal top center of each column. This directional force provides a stable vehicle lift and the columns and ramps shield the moving parts from operator contact and protect the parts from exposure thereby potentially increasing their useful life.

[0032]Referring now to the drawings in general, a vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com