Compact drive mechanism for electrically powered vehicle

a technology of electric motors and drive mechanisms, which is applied in the direction of electric propulsion mounting, electric devices, transportation and packaging, etc., can solve the problems of occupying a lot of space for motors, gearboxes, external brakes, and a large amount of space for installing batteries and other equipment, so as to reduce the overall size of electric motors and reduce the footprint or amount of space , the effect of reducing the amount of space required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention is a compact drive mechanism that frees up space, reduces weight, and improves the runtime and efficiency of powered vehicles for the handicapped.

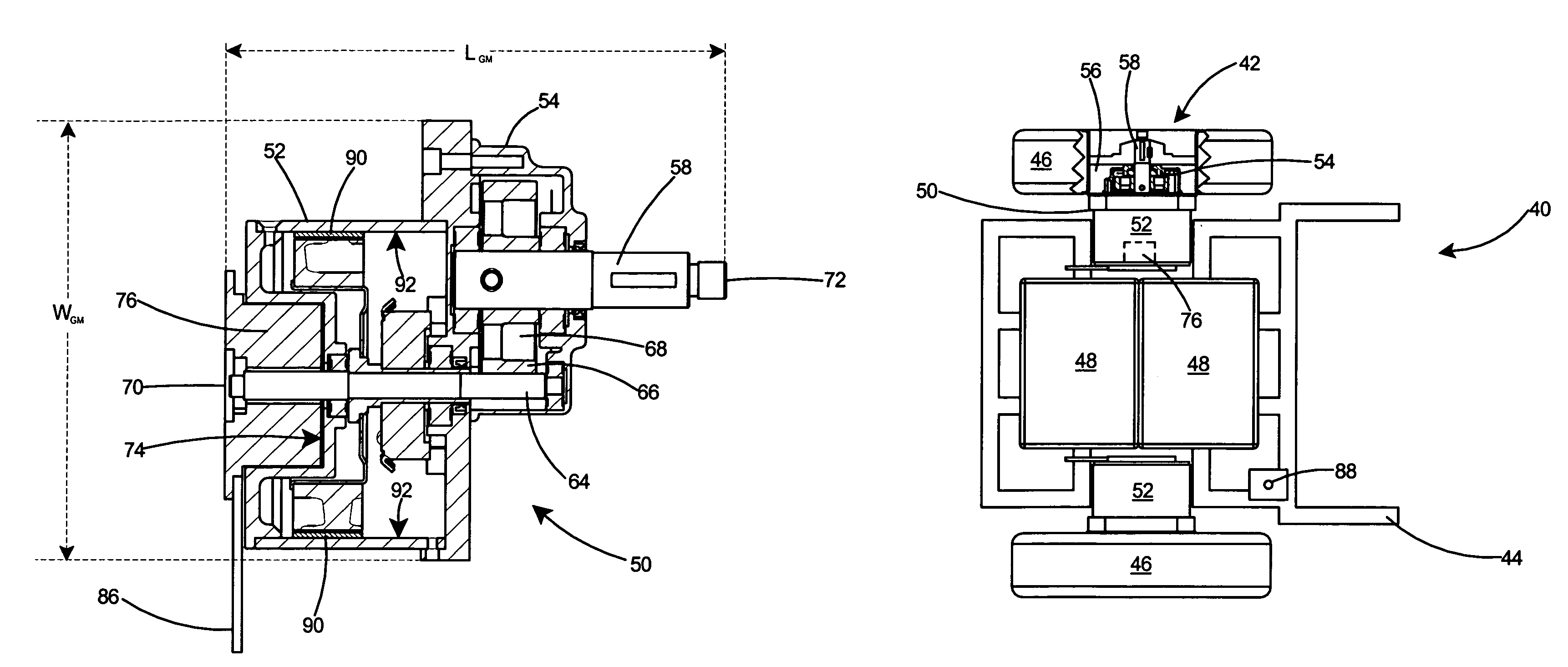

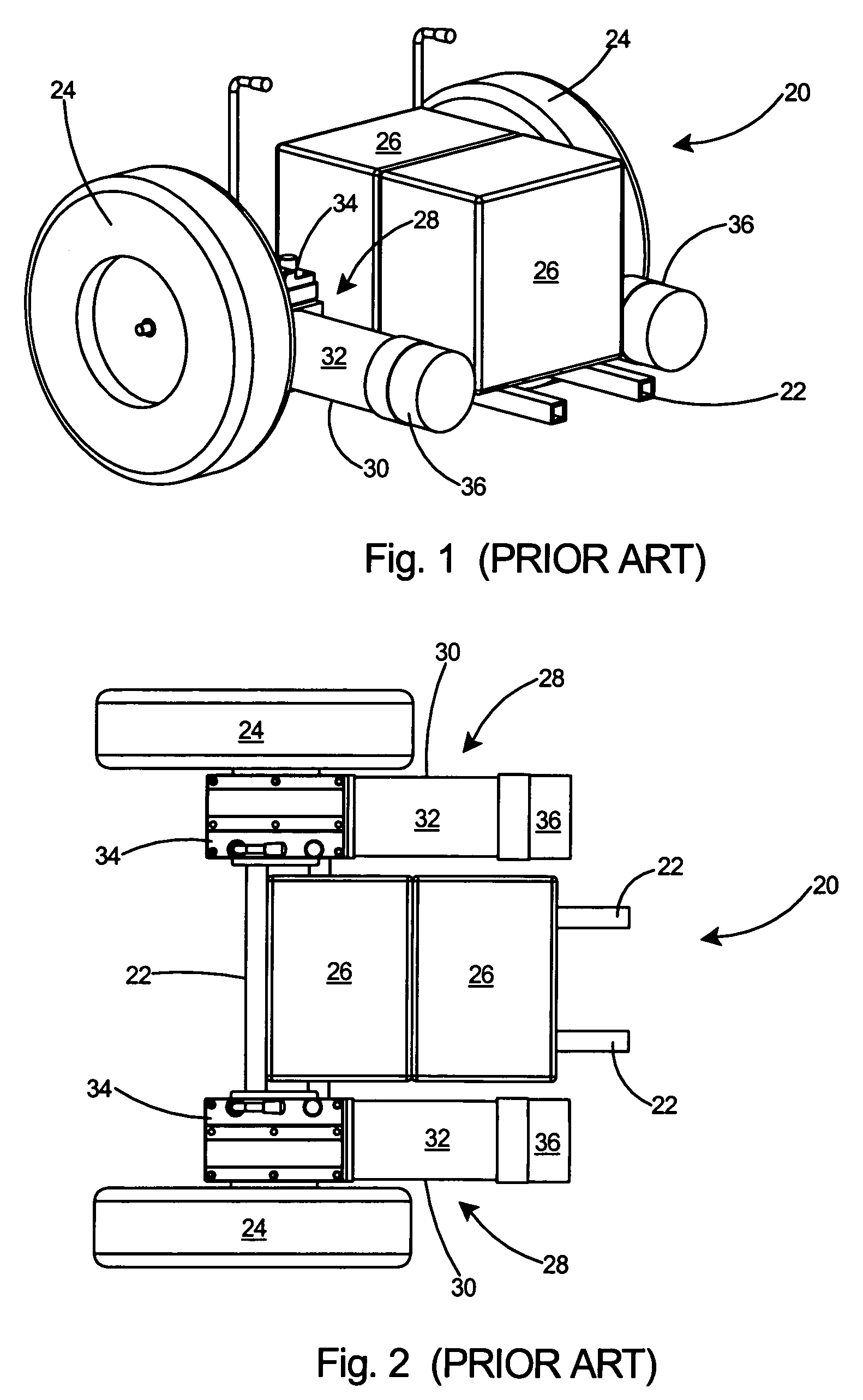

[0029]Referring to FIGS. 9 and 10, a portion of a wheelchair 40 is depicted with the compact drive mechanism 42 of the present invention installed thereon. The wheelchair 40 includes a frame 44, drive wheels 46, and batteries 48. Two compact gearmotors 50 according to the present invention are secured to the frame 44. The compact gearmotors 50 include a motor 52 and a gearbox 54. A portion of one drive wheel 46 is broken away to show the gearbox 54, which is disposed substantially within the wheel hub 56.

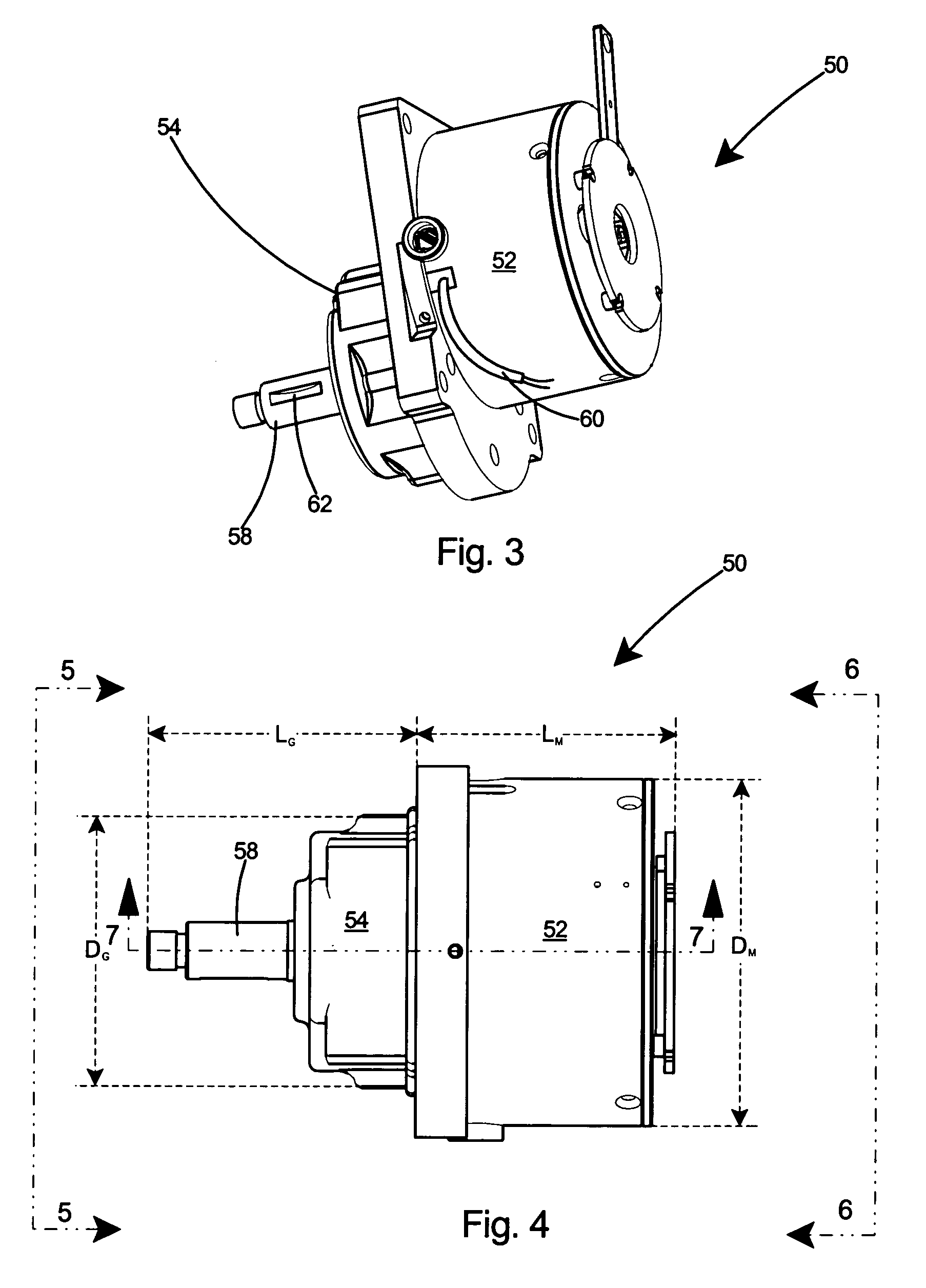

[0030]As shown in FIGS. 3 and 4, the motor 52 and gearbox 54 are joined integrally into a compact gearmotor 50. A gearbox shaft 58 extends from the gearbox. Electrical current is provided through electrical supply wiring 60 to power the motor 52 and the gearbox 54 reduces the speed of the motor to an appropriate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com