Electromechanical lock employing shape memory metal wire

a technology of electromechanical locks and metal wires, applied in the field of electromechanical locks, can solve the problems of high power consumption, inability to make conventional electromagnetic devices small to a certain degree, and the feebleness of the metal wires produced by them,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

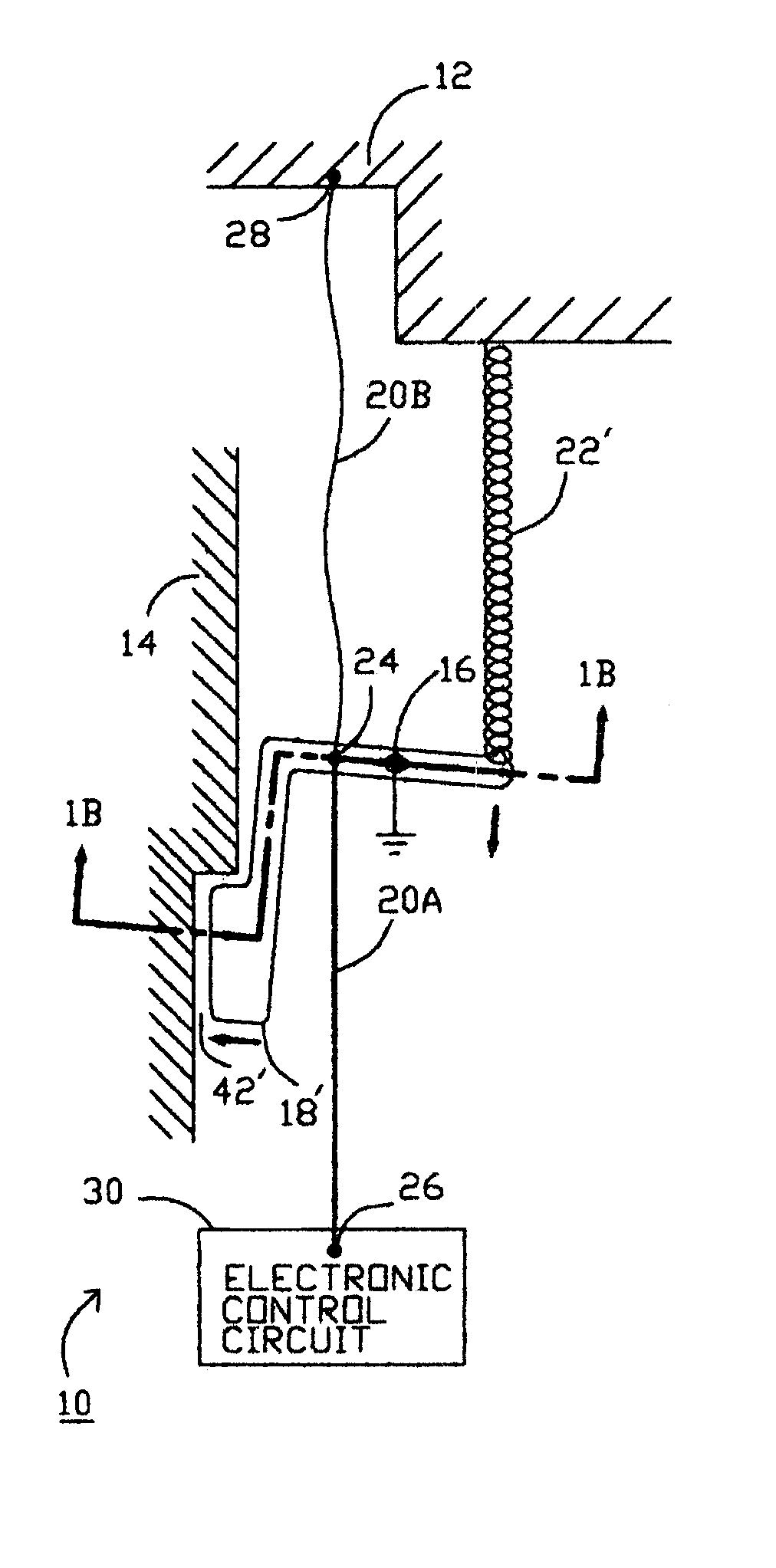

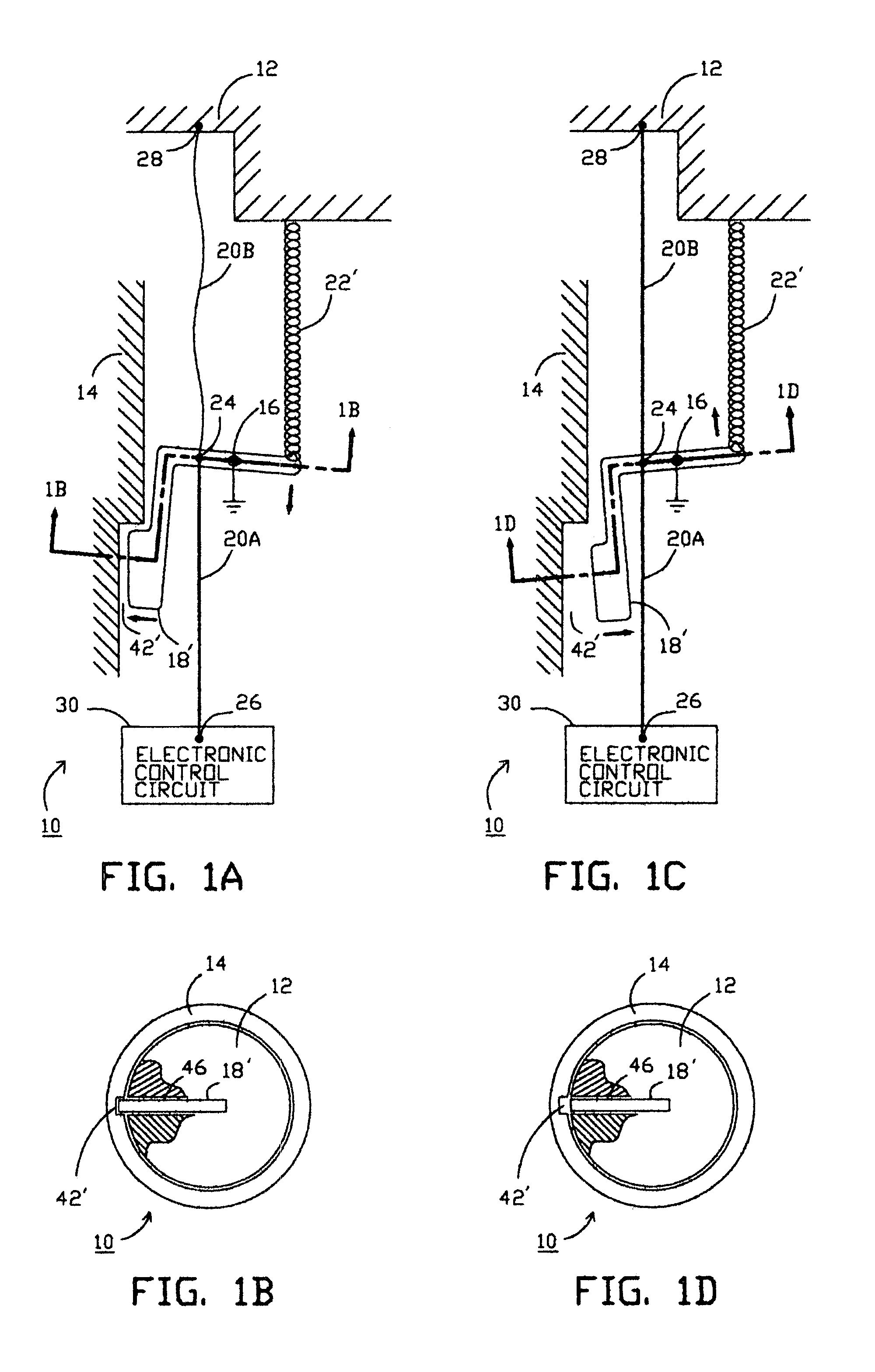

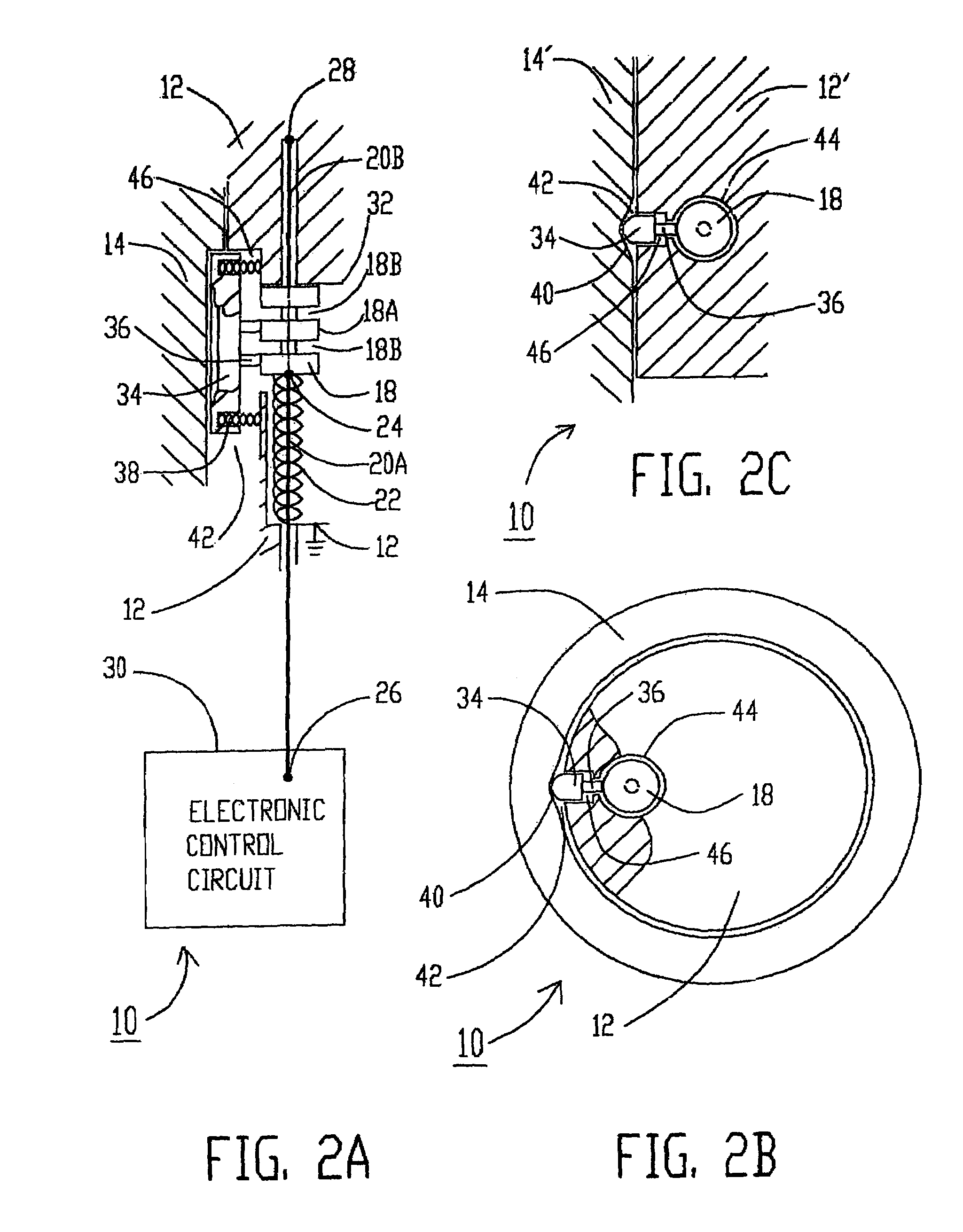

[0026]Referring to FIGS. 1A and 1B, the preferred embodiment of the electromechanical lock takes the form of a common mechanical lock cylinder 10 comprising shell 14 and plug 12. Shell 14 and plug 12 both are connected to electrical ground. Electrically conductive gate 18′ is disposed inside plug 12 with electrically conductive gate pivot 16. Gate 18′ is urged on one side by mechanical biasing means 22′, such as a spring, and is connected on the other side through attaching means 24, such as an eyelet, to shape memory metal wire 20, comprising wire segments 20A and 20B, preferably at or around the midpoint of wire 20, at the junction between the two segments. Shape memory metal wire segment 20A is connected at its other end through attaching means 26, such as an eyelet, to electronic control circuit 30. Shape memory metal wire segment 20B at its other end is anchored in the opposite direction to plug 12 by attaching means 28, such as an eyelet. Depending on what is required, the var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com