Store ejection system utilizing a mixed fuel and oxidizer in a power source

a technology of ejection system and power source, which is applied in the direction of launching weapons, machines/engines, transportation and packaging, etc., can solve the problems of safety hazards, increased cost and down time, and air flow on the underside of the aircraft that may interfere with the smooth drop of the store, so as to simplify the design of the power source and the ejector. , the effect of non-corrosive natur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

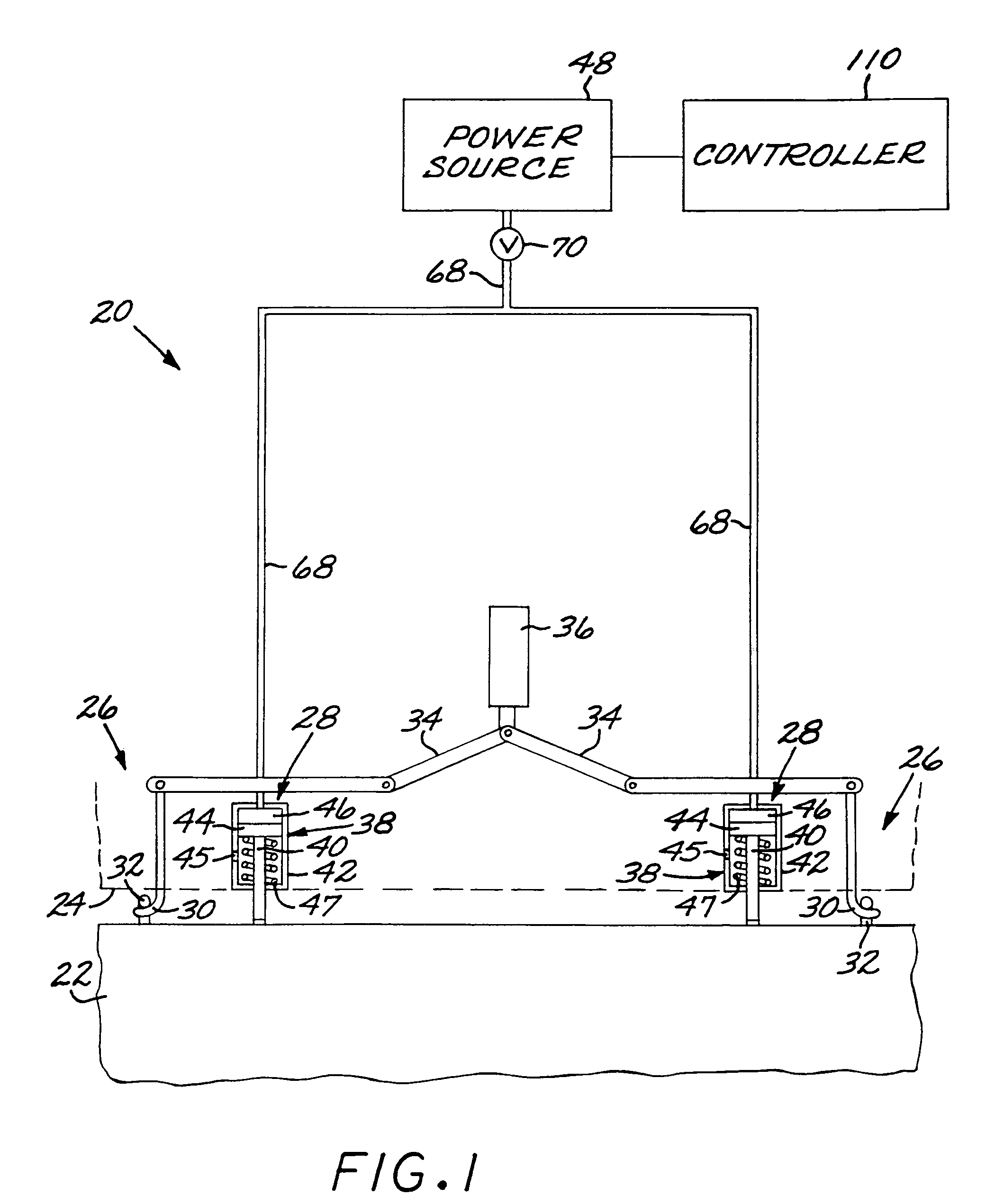

[0020]FIG. 1 depicts the relevant functional elements of a store ejection system 20. A store 22, such as a bomb, a fuel tank, or a reconnaissance pod, is supported below an aircraft 24, as from its fuselage or a wing-mounted bomb rack. The store ejection system 20 includes two main subsystems. The store 22 is supported on a store release mechanism 26, and after release is forced away from the aircraft 24 by a store-ejector subsystem 28.

[0021]The store release mechanism 26 includes a pair of suspension hooks 30 extending downwardly from the aircraft 24 and engaging a respective pair of lugs 32 extending upwardly from the store 22 to retain the store 22 supported from the aircraft 24. A mechanical linkage 34 within the aircraft 24 extends to each of the suspension hooks 30 and either holds them in position to engage the respective lugs 32 (the illustrated position), or, upon activation of the linkage 34 by a release activator 36, pivots the hooks 30 so that they no longer engage the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com