Transportable building

a technology for transporting buildings and buildings, applied in multi-purpose tools, manufacturing tools, wing accessories, etc., can solve the problems of escorting, building or module requiring over-dimensional permits and escorting, and restricting the dimensional limit set by road transport authorities for ordinary unesco loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

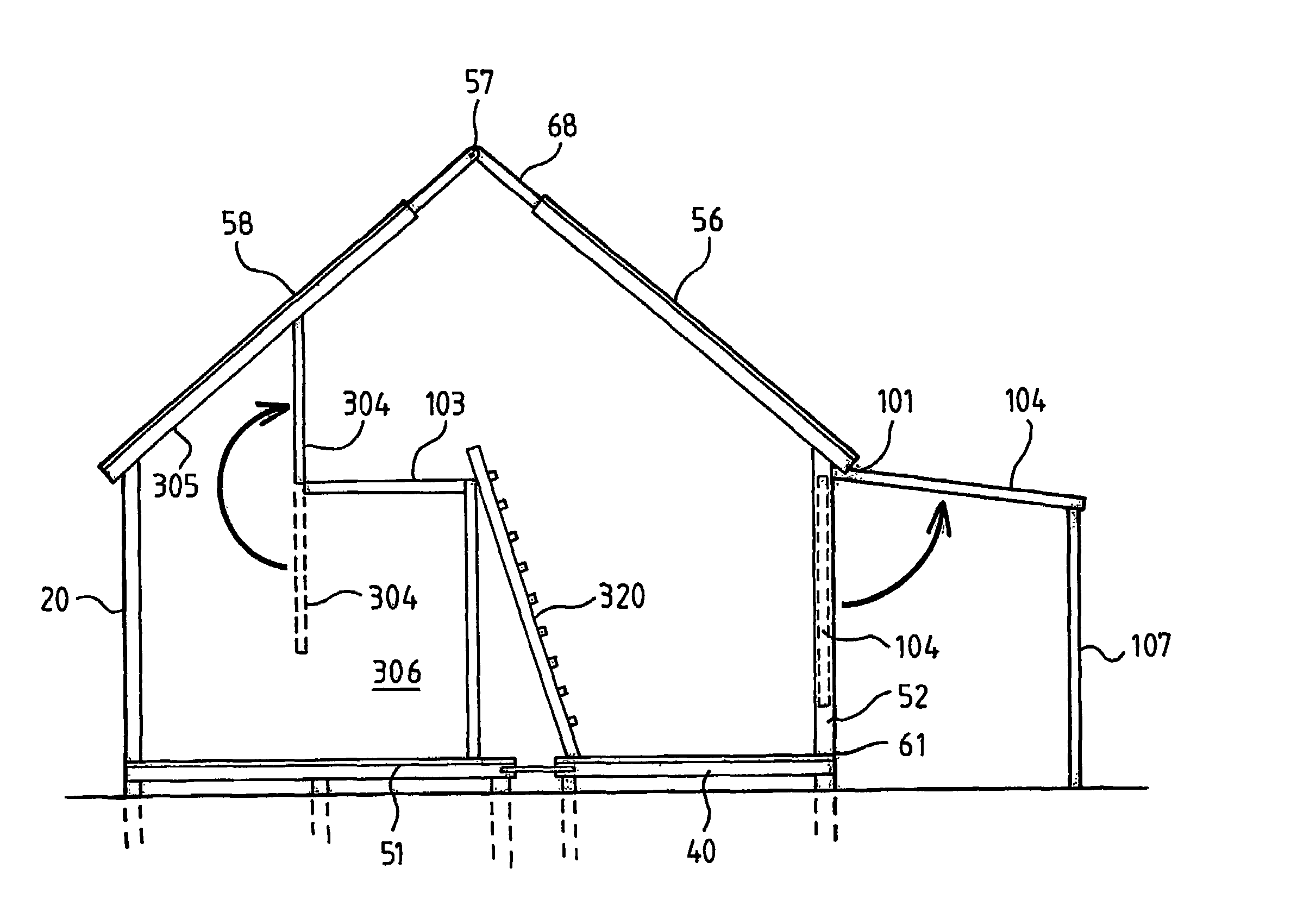

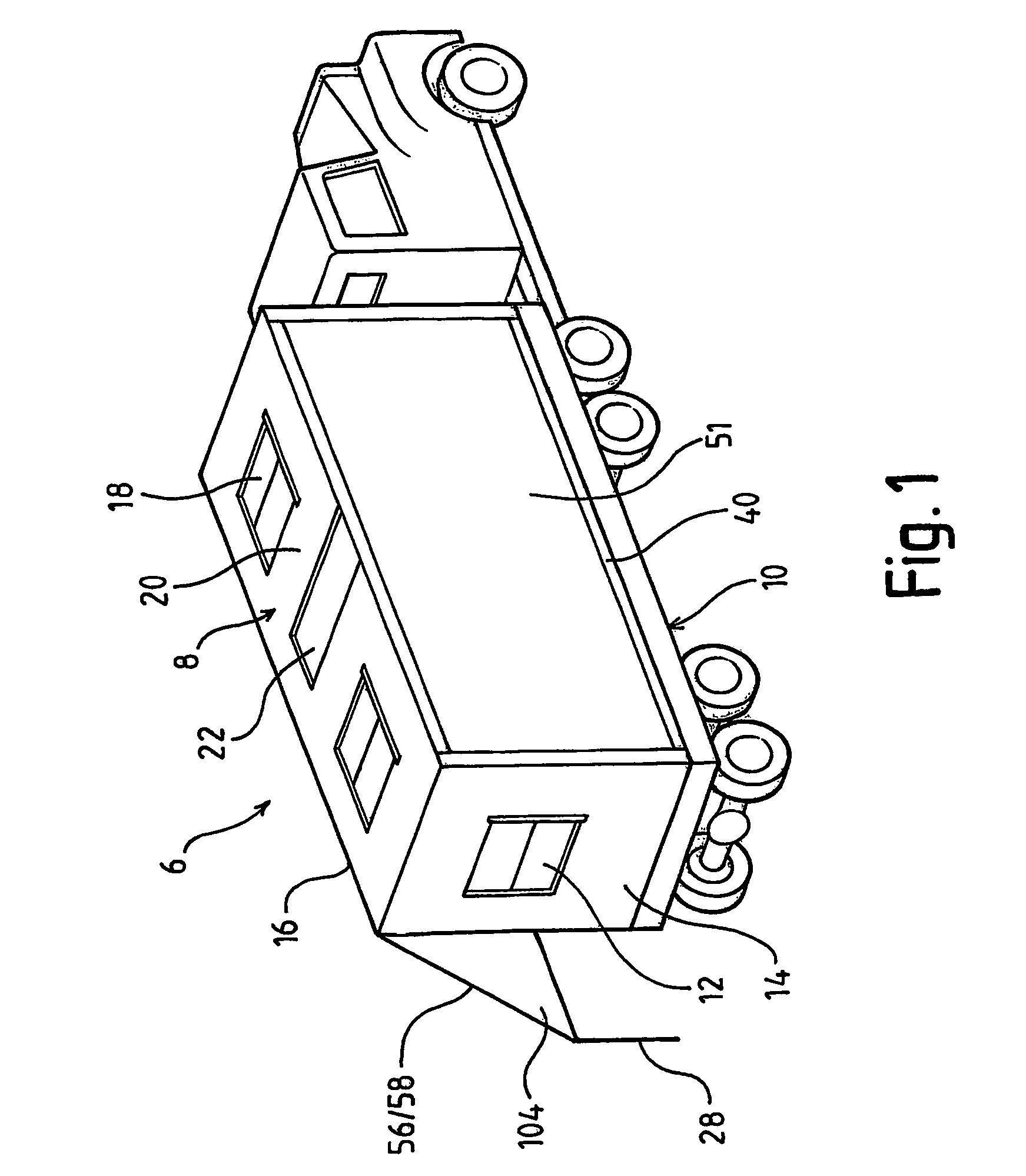

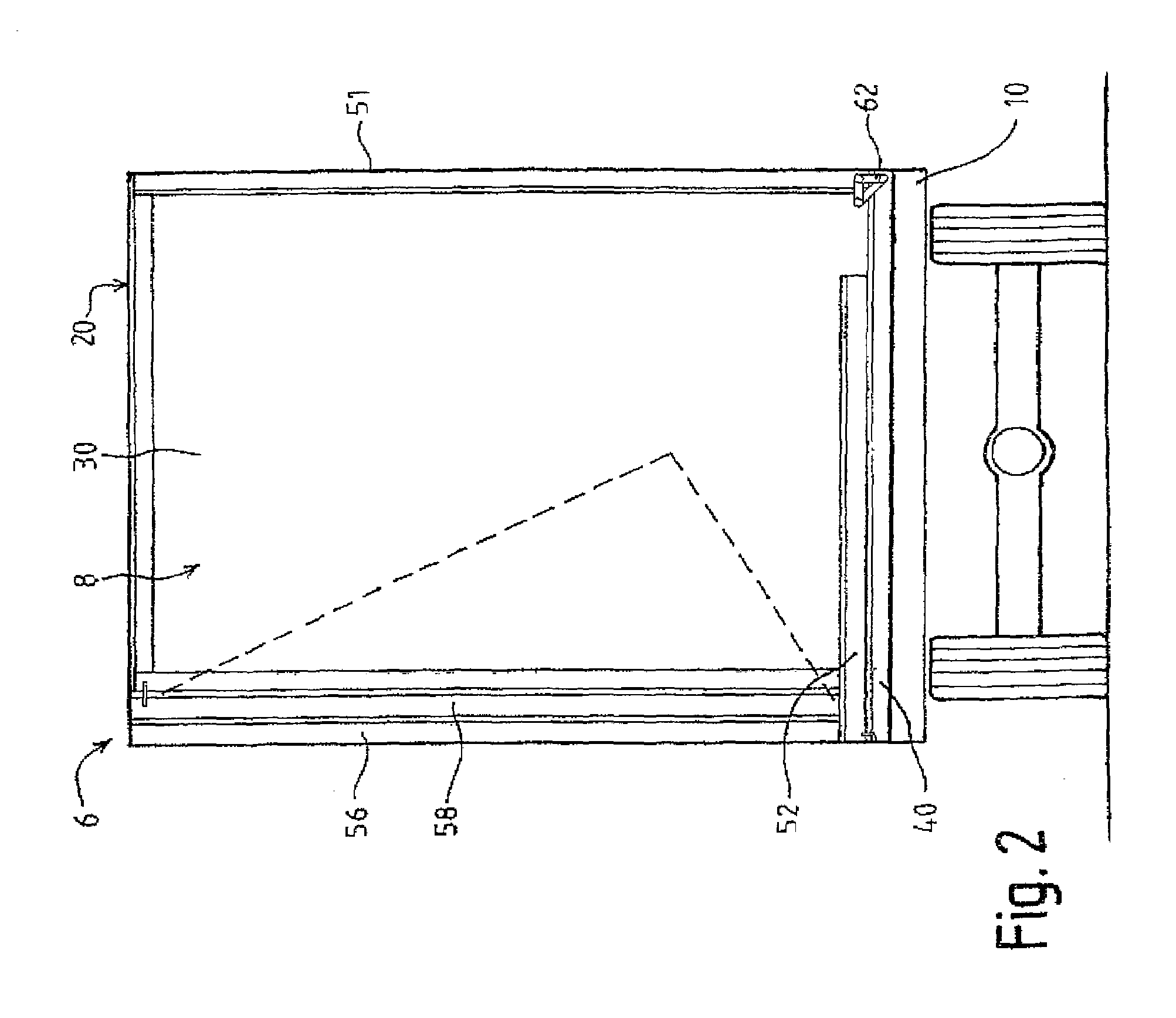

[0070]Referring to FIGS. 1 and 2, the transportable house 6, in its folded configuration on its side on a trailer 10, generally comprises an erected generally rectangular unit having the appearance and form of a box structure 8 about an enclosed space. A window 12 is formed in end walls 14 of the transportable house 6 and windows 16 and 18 are formed in sidewall 20. A door 22 is positioned approximately midway along the length of the sidewall 20. The transportable house 6 therefore comprises a pre-erected or pre-assembled unit comprising the end walls 14 and an external side wall 20. As will be explained in greater detail below, it also comprises floor panels 40, 51, roof panels 56 and 58, an external side wall 52, and an internal wall panel 54 (see FIG. 4) which is positioned opposite the side wall 20.

[0071]Although the roof panels 56 / 58 are shown in a partially open position in FIG. 1 for removal of materials from inside the transportable house 6, they are closed during transport ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com